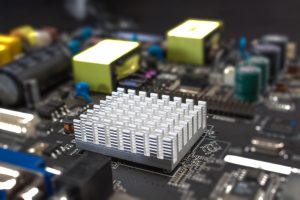

When it comes to technological applications, one thing will always remain true: thermal management capabilities are needed in order to truly help you get the most from your machines. The problem is, however, that not all applications are created the same, and sometimes it can be difficult to discern which methods are best for your particular business or industry. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a dive into the inner workings of effective heat exchangers, and details how you can achieve rapid thermal dissipation with our Copper-Finned Heat Sinks.

When it comes to technological applications, one thing will always remain true: thermal management capabilities are needed in order to truly help you get the most from your machines. The problem is, however, that not all applications are created the same, and sometimes it can be difficult to discern which methods are best for your particular business or industry. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a dive into the inner workings of effective heat exchangers, and details how you can achieve rapid thermal dissipation with our Copper-Finned Heat Sinks.

Air To Air Thermal Management

To effectively optimize your thermal management capabilities, we must first gain an understanding of your unique parameters, including environment, location, purpose, and space allotted. While many applications are unique in nature and thus require custom heat exchangers, others may only require an effective filter, fan, or other accessories to streamline productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the versatility behind our Eco-Flow Dual Filter Fan, and how we can help you get the most from air-to-air thermal management.

To effectively optimize your thermal management capabilities, we must first gain an understanding of your unique parameters, including environment, location, purpose, and space allotted. While many applications are unique in nature and thus require custom heat exchangers, others may only require an effective filter, fan, or other accessories to streamline productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the versatility behind our Eco-Flow Dual Filter Fan, and how we can help you get the most from air-to-air thermal management.

Addressing Hazardous Location Needs

Advances in industrial technology have made it possible to create unique thermal management solutions that can produce optimal results. In a world where competition is booming and customization is key, the ability to design products to meet specific parameters is necessary. What’s more? There are other considerations that must be accounted for to ensure optimal use, including purpose, environment, and ability to work in tough conditions. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance behind quality application cooling, and how we can help address your needs, even in difficult environments.

Advances in industrial technology have made it possible to create unique thermal management solutions that can produce optimal results. In a world where competition is booming and customization is key, the ability to design products to meet specific parameters is necessary. What’s more? There are other considerations that must be accounted for to ensure optimal use, including purpose, environment, and ability to work in tough conditions. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the importance behind quality application cooling, and how we can help address your needs, even in difficult environments.

Cooling With Heat Pipe Heat Exchangers

To protect your devices from overheating is one thing, but to provide ideal enclosure cooling for a variety of applications is completely different. In fact, there are countless companies out there that advertise effective thermal management, but achieve this concept at a major cost to the environment. What’s more, many products are designed with a one-size-fits-all mindset and do not account for the unique needs of different technologies, let alone the space allotted for them. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the complications that arise from these issues, and how a custom heat pipe installation can help.

To protect your devices from overheating is one thing, but to provide ideal enclosure cooling for a variety of applications is completely different. In fact, there are countless companies out there that advertise effective thermal management, but achieve this concept at a major cost to the environment. What’s more, many products are designed with a one-size-fits-all mindset and do not account for the unique needs of different technologies, let alone the space allotted for them. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the complications that arise from these issues, and how a custom heat pipe installation can help.

Ideal Filter Fan Enclosure Cooling

It goes without saying that your thermal management capabilities are largely influenced by a variety of factors. To make sure your applications are functioning in an optimal manner, one must consider their size, purpose, location, environment, and more. Indeed, thermal management extends further than just preventing overheating but ensuring that the inner workings of your applications are safe and protected as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the importance of preventing dust, dirt, and other debris from affecting your applications, and how filter fan thermal management can help.

It goes without saying that your thermal management capabilities are largely influenced by a variety of factors. To make sure your applications are functioning in an optimal manner, one must consider their size, purpose, location, environment, and more. Indeed, thermal management extends further than just preventing overheating but ensuring that the inner workings of your applications are safe and protected as well. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the importance of preventing dust, dirt, and other debris from affecting your applications, and how filter fan thermal management can help.

Heat Absorption With Cold Plates

Having a custom-made heat exchanger designed with your unique parameters in mind is incredibly helpful in getting the most from your technological applications. What’s more, an understanding of why those parameters are in place in the first place is necessary to provide effective and efficient thermal management capabilities. Still, some products are more effective than others, and you truly will not know until you learn more about their unique capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how cold plates can provide effective heat absorption, thus benefitting your business.

Having a custom-made heat exchanger designed with your unique parameters in mind is incredibly helpful in getting the most from your technological applications. What’s more, an understanding of why those parameters are in place in the first place is necessary to provide effective and efficient thermal management capabilities. Still, some products are more effective than others, and you truly will not know until you learn more about their unique capabilities. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses how cold plates can provide effective heat absorption, thus benefitting your business.

How Customization Optimizes Output

Depending on your environment and parameters, your business may benefit from a certain type of heat exchanger as opposed to another. Even still, just because a passive device is better suited for your applications than an active one, that does not mean that the generic version of a product will work in an optimal fashion. Indeed, we are long past the notion of a one-size-fits-all mentality, and our team recognizes that much more goes into creating your custom heat exchanger than other companies may think. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX focuses on the importance of customization when designing your products, as well as how it can lead to cost-effective thermal management.

Depending on your environment and parameters, your business may benefit from a certain type of heat exchanger as opposed to another. Even still, just because a passive device is better suited for your applications than an active one, that does not mean that the generic version of a product will work in an optimal fashion. Indeed, we are long past the notion of a one-size-fits-all mentality, and our team recognizes that much more goes into creating your custom heat exchanger than other companies may think. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX focuses on the importance of customization when designing your products, as well as how it can lead to cost-effective thermal management.

Different Benefits of Passive Cooling

It goes without saying that most industries utilize thermal management capabilities in one way or another in order to prevent overheating and increase production. Indeed, items such as accessories and custom heat exchangers make this notion possible, aiding our industrialized society greatly. What’s more, some manufacturers are able to kick it up a notch by offering options that optimize output, thus making the entire process that much more effective. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss a few different methods for natural application cooling, and how our custom products can help.

It goes without saying that most industries utilize thermal management capabilities in one way or another in order to prevent overheating and increase production. Indeed, items such as accessories and custom heat exchangers make this notion possible, aiding our industrialized society greatly. What’s more, some manufacturers are able to kick it up a notch by offering options that optimize output, thus making the entire process that much more effective. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss a few different methods for natural application cooling, and how our custom products can help.

Accessories For Heat Management Needs

Whether you are dealing with electrical equipment in a wastewater setting or constantly enduring rough conditions such as within the military or drilling for oil, your equipment plays a major role in your job. In fact, it is likely that a large portion of your role depends highly on your applications to perform a specified task, and when complications arise such as overheating or breaking down, the entire business suffers. Because of this, an emphasis is placed on proper temperature regulation and thermal management. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the need for application accessories, and how low-effort maintenance can encourage proper filter fan enclosure cooling.

Whether you are dealing with electrical equipment in a wastewater setting or constantly enduring rough conditions such as within the military or drilling for oil, your equipment plays a major role in your job. In fact, it is likely that a large portion of your role depends highly on your applications to perform a specified task, and when complications arise such as overheating or breaking down, the entire business suffers. Because of this, an emphasis is placed on proper temperature regulation and thermal management. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the need for application accessories, and how low-effort maintenance can encourage proper filter fan enclosure cooling.

Water Protection And NEMA Enclosures

As you may be aware, not all technological applications are created equally, and many are designed with industry-specific functions in mind. After all, the equipment used for mold cooling purposes is going to be far different from enclosures used in an Oil & Gas setting. What’s more, the purpose is not the only key identifier, as factors such as environment, space allotted, and even industry needs must be considered when attempting to optimize your equipment. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX is going to take a look at these concepts with respect to wastewater treatment, and explain how adhering to standards can optimize NEMA 4X enclosure cooling.

As you may be aware, not all technological applications are created equally, and many are designed with industry-specific functions in mind. After all, the equipment used for mold cooling purposes is going to be far different from enclosures used in an Oil & Gas setting. What’s more, the purpose is not the only key identifier, as factors such as environment, space allotted, and even industry needs must be considered when attempting to optimize your equipment. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX is going to take a look at these concepts with respect to wastewater treatment, and explain how adhering to standards can optimize NEMA 4X enclosure cooling.