NATURAL CONVECTION COOLING

NATURAL CONVECTION COOLING

Convection is a type of heat transfer which occurs only due to density differences in the fluid due to temperature gradients. In natural convection, fluid surrounding a heat source receives heat, becomes less dense and rises up. The surrounding fluid then moves to replace it. This cooler fluid is then heated and the process continues, forming convection current. Since there is no external fan to accelerate the heat transfer, the design of the heat sink should be thermally efficient to dissipate maximum amount of heat.

This type of cooling is employed when forced convection cannot be used in the system because of space constraints, power limitations, noise etc.

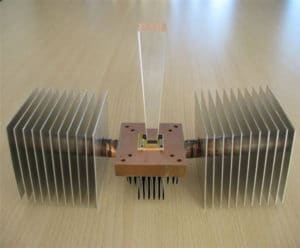

HIGH POWER DENSITY HEAT SINK ASSEMBLIES

HIGH POWER DENSITY HEAT SINK ASSEMBLIES

Noren pioneers in providing solutions for efficient high power heat dissipation, high heat flux, heat spreading and other high heat management problems.

IGBT modules are one of the applications where Noren’s heat sink assemblies are designed for high power and lower overall thermal resistance.

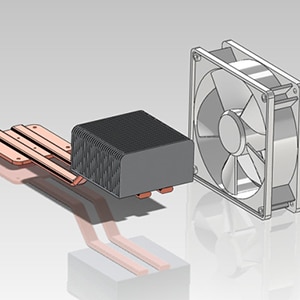

FORCED CONVECTION COOLING

FORCED CONVECTION COOLING

Design Analysis Forced convection is a type of heat transfer in which an external source (like a fan etc) is used to generate fluid motion and increase the heat transfer.

The most common perception is that higher the flow, higher the forced convection, therefore higher the cooling. This is not true because there many of other parameters which determine the amount of forced convection other than the CFM of the fan. One important parameter is the pressure drop across the heat sink. The greater the pressure drop across the heat sink, the lower the flow rate for the same fan, therefore the lower the forced convection. Therefore, the design of a heat sink is not as straight-forward as it appears to be.

At Noren we help you design the most efficient heat sink for your application to maximize the heat dissipated for the same.

Noren Heat Pipes Made Heat Exchangers Viable for Hazardous Locations

Today, heat exchangers are widely recognized as more efficient and cost-effective solutions to managing electrical waste heat. Yet, it wasn’t until the introduction of Noren’s heat pipe technology that heat exchangers could be certified to operate in hazardous locations. Noren Thermal was the first manufacturer to receive national and international certification for HX applications in hazardous conditions, paving the way for heat exchangers to revolutionize industries such as oil and gas, power generation, waste water treatment, food processing, and more.

What Are Hazardous Locations?

Hazardous locations are those in which the potential for fires and explosions is amplified by the presence of flammable substances. By necessity, all equipment utilized in hazardous locations must meet specific design, installation, and operation requirements to avoid the elements of the “fire triangle.” These elements include:

- a flammable substance, such as propane gases or agricultural dust;

- an ignition source, such as sparks or high heat;

- and air or oxygen

Air cannot be avoided, and in many industries, flammable substances are at the center of operations. Because heat exchangers previously relied on aluminum sheets, they could generate sparks and complete the fire triangle in hazardous locations.

How Heat Pipes Work

Rather than aluminum sheets, Noren heat exchangers utilize heat pipes that dissipate waste heat away from electrical panels without creating a static or electrical charge. Small fans help draw heated air over the core to prevent hot spots, and neoprene gaskets and flanges prevent air contamination inside and outside of the panel. The fans are the heat exchanger’s only moving parts and don’t require an external circuit board, which significantly cuts the costs of maintenance and down-time, and considerably reduces energy consumption.

Leading Innovators in Thermal Management Solutions

Noren’s heat pipe core technology was the first to be awarded UL/cUL, ATEX and IECEx certifications for use in Class I, Division 2 (Europe—Class I/Zone 2) hazardous locations. In addition to Underwriters Laboratory, Noren has accreditation for ISO 9001:2008 and for GSA contracts. To learn more about our innovative thermal management solutions, call Noren Thermal, Inc. at 512-595-5700. Located in Menlo Park, CA, Noren proudly produces all of our products in the United States and delivers them to clients nationwide.

Have Questions? We're Ready to Help!

Products

Noren thermal solutions are designed to cool overheating electronics in a variety of industries and applications. Check out our PRODUCTS section for more information.