It goes without saying that various technological applications require different methods to meet their thermal management needs, and believing a one-size-fits all solution will help is foolish. Indeed, technology has taken the world by storm as we move toward a technology-driven age of information. Whether we are dealing with an oil rig, a manufacturing plant, or even an elevator, it takes a thorough understanding of the different variables involved in order to provide an effective solution, and our team is ready to help. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the concepts behind our HyTec cooler that help achieve consistency through use.

It goes without saying that various technological applications require different methods to meet their thermal management needs, and believing a one-size-fits all solution will help is foolish. Indeed, technology has taken the world by storm as we move toward a technology-driven age of information. Whether we are dealing with an oil rig, a manufacturing plant, or even an elevator, it takes a thorough understanding of the different variables involved in order to provide an effective solution, and our team is ready to help. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the concepts behind our HyTec cooler that help achieve consistency through use.

Meeting Needs In Wastewater Applications

While every technological application shares one commonality in that there is a prevalent need for thermal management, not all electronics are the same. After all, you would not expect the needs of two drastically different industries to coincide in their entirety, so why would you think all applications have the same needs? Because of this, a thorough understanding of a variety of factors is needed, including purpose, location, environment, and more. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes the time to discuss the importance of meeting NEMA standards in a variety of applications, including those in the wastewater industry.

While every technological application shares one commonality in that there is a prevalent need for thermal management, not all electronics are the same. After all, you would not expect the needs of two drastically different industries to coincide in their entirety, so why would you think all applications have the same needs? Because of this, a thorough understanding of a variety of factors is needed, including purpose, location, environment, and more. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes the time to discuss the importance of meeting NEMA standards in a variety of applications, including those in the wastewater industry.

Thermal Pins Optimize Plastic Cooling

In order to streamline enclosure cooling for a variety of applications, a thorough understanding of the technological needs and parameters must first be acquired. What’s more, not every industry is created equally, and as such, what might work for one application cannot certainly be guaranteed to work for the next. Indeed, whether the goal is increased yields, high thermal conductivity, or simply rapid cooling, our team is prepared to help you find your ideal cooling solution. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the need for rapid cooling in industries that utilize molds, and how a thermal pin might just be the answer.

In order to streamline enclosure cooling for a variety of applications, a thorough understanding of the technological needs and parameters must first be acquired. What’s more, not every industry is created equally, and as such, what might work for one application cannot certainly be guaranteed to work for the next. Indeed, whether the goal is increased yields, high thermal conductivity, or simply rapid cooling, our team is prepared to help you find your ideal cooling solution. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the need for rapid cooling in industries that utilize molds, and how a thermal pin might just be the answer.

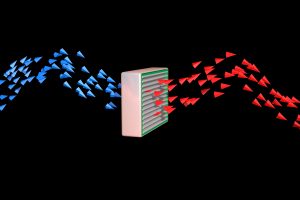

Streamlined Enclosure Cooling With Heat Pipes

When it comes to streamlining your enclosure cooling, there are a variety of methods that can be used to get the job done. Indeed, from transfer through air-to-water methods to dissipation through thermal sinks, each method used offers a unique experience that serves to address your specific parameters in innovative and eco-friendly ways. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to take a look at the way our custom heat pipes can help this process through optimizing your enclosure’s cooling capabilities.

When it comes to streamlining your enclosure cooling, there are a variety of methods that can be used to get the job done. Indeed, from transfer through air-to-water methods to dissipation through thermal sinks, each method used offers a unique experience that serves to address your specific parameters in innovative and eco-friendly ways. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX would like to take a look at the way our custom heat pipes can help this process through optimizing your enclosure’s cooling capabilities.

Air To Water Application Cooling

Ideal application cooling is a goal that many companies strive to achieve. After all, the job must get done and a number of industries rely heavily on equipment and other applications to make it happen. Nowadays, however, it is not enough to ensure an application does not overheat but to accomplish this while also optimizing yield and productivity. Fortunately, a number of methods and technologies have been utilized to help make this happen. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at phase-change technology in particular, and discuss the ways that air to water cooling optimizes output.

Ideal application cooling is a goal that many companies strive to achieve. After all, the job must get done and a number of industries rely heavily on equipment and other applications to make it happen. Nowadays, however, it is not enough to ensure an application does not overheat but to accomplish this while also optimizing yield and productivity. Fortunately, a number of methods and technologies have been utilized to help make this happen. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at phase-change technology in particular, and discuss the ways that air to water cooling optimizes output.

Ideal Cooling For NEMA-12 Enclosures

Some industries contain extreme conditions and variations in the environment that cause them to require custom technological applications and equipment to withstand these fluctuations. Indeed, hazardous locations and extreme conditions play a major factor when testing and creating optimal temperature management accessories. Other industries, however, may only need an enclosure that withstands normal conditions, such as with typical indoor industrial use. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the functions of NEMA. 12 enclosures, and how our team meets and exceeds the standards put in place for proper function.

Some industries contain extreme conditions and variations in the environment that cause them to require custom technological applications and equipment to withstand these fluctuations. Indeed, hazardous locations and extreme conditions play a major factor when testing and creating optimal temperature management accessories. Other industries, however, may only need an enclosure that withstands normal conditions, such as with typical indoor industrial use. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the functions of NEMA. 12 enclosures, and how our team meets and exceeds the standards put in place for proper function.

Application Cooling With Ambient Air

It goes without saying that proper application cooling and thermal management can be accomplished in a variety of ways. From the method used to transfer heat to the specific technology utilized, an effective, eco-friendly product can be created and implemented to not only meet your specific parameters but do so in a manner that favors productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look into one of the many products we offer – ambient cooling units – and just how they function to accomplish your goals.

It goes without saying that proper application cooling and thermal management can be accomplished in a variety of ways. From the method used to transfer heat to the specific technology utilized, an effective, eco-friendly product can be created and implemented to not only meet your specific parameters but do so in a manner that favors productivity. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look into one of the many products we offer – ambient cooling units – and just how they function to accomplish your goals.

Heat Transfer Over Distances With Cold Plates

Getting the most out of your heat exchanger has become a must for a variety of industries nowadays. Whereas prevention of overheating was the top priority in the past, efficiency and productivity are the major concerns of the present. What’s more, a demand has been created for accessories that can accomplish these goals while also taking up as little space as possible, somewhat throwing a wrench into the equation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discuss the ways that our custom products such as our cold plates can meet these parameters and help you get the most out of your equipment.

Getting the most out of your heat exchanger has become a must for a variety of industries nowadays. Whereas prevention of overheating was the top priority in the past, efficiency and productivity are the major concerns of the present. What’s more, a demand has been created for accessories that can accomplish these goals while also taking up as little space as possible, somewhat throwing a wrench into the equation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discuss the ways that our custom products such as our cold plates can meet these parameters and help you get the most out of your equipment.

Updating Your Cooling Capabilities

Staying ahead of the curve in a variety of ways often involves consistent innovation. What’s more, recognizing the unique needs and parameters of a client is crucial to ensure complete satisfaction. With all of this in mind, it would be foolish to believe that your current technological set-up is the best of what is offered, especially after years of use. Indeed, adequate application cooling is a thing of the past, as optimal solutions lead the movement. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the importance of consistent innovation when it comes to generating optimal yield and productivity in a given industry.

Staying ahead of the curve in a variety of ways often involves consistent innovation. What’s more, recognizing the unique needs and parameters of a client is crucial to ensure complete satisfaction. With all of this in mind, it would be foolish to believe that your current technological set-up is the best of what is offered, especially after years of use. Indeed, adequate application cooling is a thing of the past, as optimal solutions lead the movement. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the importance of consistent innovation when it comes to generating optimal yield and productivity in a given industry.

Personalized Products With Collaborative Engineering

NEMA-specific standards make creating custom thermal solutions much more efficient, as they provide a guideline of goals that must be met in order for a number of solutions to become UL certified. What’s more, they take unique needs into consideration, as NEMA’s line of standards vary depending on the product itself and what industry it is intended to be used for. In today’s blog, your team at Noren Thermal Solutions in Taylor, TX take an in-depth approach to helping our clients understand how collaborative engineering plays a major role in personalized products.

NEMA-specific standards make creating custom thermal solutions much more efficient, as they provide a guideline of goals that must be met in order for a number of solutions to become UL certified. What’s more, they take unique needs into consideration, as NEMA’s line of standards vary depending on the product itself and what industry it is intended to be used for. In today’s blog, your team at Noren Thermal Solutions in Taylor, TX take an in-depth approach to helping our clients understand how collaborative engineering plays a major role in personalized products.