The science of transferring and dissipating electrical waste heat has advanced significantly over the last several decades. With a wide variety of heat exchangers and spreaders taking the place of more expensive (and less reliable) solutions like air conditioning, companies can significantly improve productivity and streamline their operations. Among this variety, cold plates are often the preferred solution for systems that require consistent cooling across an area that is too large for more compact heat exchangers to effectively handle. (more…)

The science of transferring and dissipating electrical waste heat has advanced significantly over the last several decades. With a wide variety of heat exchangers and spreaders taking the place of more expensive (and less reliable) solutions like air conditioning, companies can significantly improve productivity and streamline their operations. Among this variety, cold plates are often the preferred solution for systems that require consistent cooling across an area that is too large for more compact heat exchangers to effectively handle. (more…)

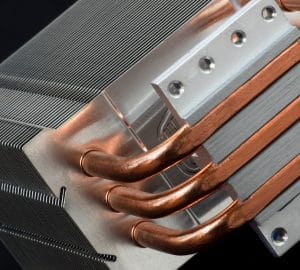

Using Heat Pipes for the Most Demanding Applications

For over 40 years, Noren has excelled at providing innovative heat exchanger technology to suit a dynamic range of needs and applications. Today, heat pipes remain one of the most effective and reliable solutions for applications that require high performance with little or no maintenance. For instance, heat pipes do not consist of external moving parts, and therefore, they’re often preferred for applications such as aerospace technology and computer processing. Yet, this is only an advantage because heat pipes are also able to transfer heat at high rates with consistent reliability. (more…)

For over 40 years, Noren has excelled at providing innovative heat exchanger technology to suit a dynamic range of needs and applications. Today, heat pipes remain one of the most effective and reliable solutions for applications that require high performance with little or no maintenance. For instance, heat pipes do not consist of external moving parts, and therefore, they’re often preferred for applications such as aerospace technology and computer processing. Yet, this is only an advantage because heat pipes are also able to transfer heat at high rates with consistent reliability. (more…)

3 More Industries that Have Benefited from Heat Exchangers

Over the last several decades, there have been countless technological innovations that have helped companies boost productivity, improve product quality, and lower overall operating costs. Among those innovations, heat exchangers stand apart as one of the most impactful. Thanks to advanced thermal management solutions like heat exchangers, all industries have been able to streamline almost every aspect of their operations. They’ve also been able to reduce energy consumption, thereby lowering their environmental footprint. (more…)

Over the last several decades, there have been countless technological innovations that have helped companies boost productivity, improve product quality, and lower overall operating costs. Among those innovations, heat exchangers stand apart as one of the most impactful. Thanks to advanced thermal management solutions like heat exchangers, all industries have been able to streamline almost every aspect of their operations. They’ve also been able to reduce energy consumption, thereby lowering their environmental footprint. (more…)

How Are Heat Exchangers Used in the Pharmaceutical Industry?

Heat exchangers are a popular choice for cooling control panels and electrical enclosures more efficiently than alternative methods, most notably in fields of manufacturing. Yet, heat exchanger technology has also changed the dynamics of pharmaceutical production and packaging in many of the same ways. In the pharmaceutical industry, managing electrical waste heat and providing consistent thermal management is vital to most processes, including the fine chemistry needed to create pharmaceutical drugs and products. (more…)

Heat exchangers are a popular choice for cooling control panels and electrical enclosures more efficiently than alternative methods, most notably in fields of manufacturing. Yet, heat exchanger technology has also changed the dynamics of pharmaceutical production and packaging in many of the same ways. In the pharmaceutical industry, managing electrical waste heat and providing consistent thermal management is vital to most processes, including the fine chemistry needed to create pharmaceutical drugs and products. (more…)

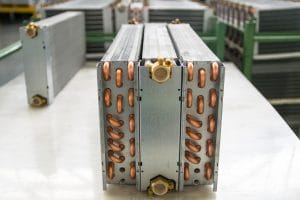

A Better Way to Cool Electrical Control Panels

When it comes to keeping electrical control panels properly cooled, Noren’s heat exchangers have continued to raise the bar in quality, efficiency, and reliability. With a variety of different design models and the ability to customize any design to meet clients’ unique needs, Noren offers a better way to cool electrical control panels than most other options. From saving companies money on energy to freeing up staff with less demanding maintenance needs, heat exchangers continue to outperform other thermal management solutions for most electrical control panels. (more…)

When it comes to keeping electrical control panels properly cooled, Noren’s heat exchangers have continued to raise the bar in quality, efficiency, and reliability. With a variety of different design models and the ability to customize any design to meet clients’ unique needs, Noren offers a better way to cool electrical control panels than most other options. From saving companies money on energy to freeing up staff with less demanding maintenance needs, heat exchangers continue to outperform other thermal management solutions for most electrical control panels. (more…)

Do Air-to-Air Heat Exchangers Protect from Contamination?

Among their many benefits, heat exchangers provide the advantage of utilizing forces like natural or forced convection to make electrical thermal management much simpler and less costly. Without the need for clunky air conditioning equipment, heat exchangers can keep air within an electrical enclosure flowing to prevent heat pockets from forming. Yet, it may not be immediately obvious how air-to-air heat exchangers protect the enclosures they cool from contaminants in the air. The secret is that outside air is not part of an air-to-air heat exchanger’s operation. In fact, keeping outside air out is a significant reason why heat exchangers are so successful. (more…)

Among their many benefits, heat exchangers provide the advantage of utilizing forces like natural or forced convection to make electrical thermal management much simpler and less costly. Without the need for clunky air conditioning equipment, heat exchangers can keep air within an electrical enclosure flowing to prevent heat pockets from forming. Yet, it may not be immediately obvious how air-to-air heat exchangers protect the enclosures they cool from contaminants in the air. The secret is that outside air is not part of an air-to-air heat exchanger’s operation. In fact, keeping outside air out is a significant reason why heat exchangers are so successful. (more…)

2 Ways Heat Exchangers Immediately Reduce Costs

For engineers endeavoring to create the latest, most powerful technology to manufacturers who want to reduce their overhead costs, heat exchangers are often the most attractive thermal management solutions. In the long run, upgrading to heat exchangers from traditional air conditioning units provides significant benefits. However, many of those benefits can be seen almost immediately after the change. The following are just two of the several ways in which heat exchangers can immediately reduce the costs of effective thermal management for virtually any application. (more…)

For engineers endeavoring to create the latest, most powerful technology to manufacturers who want to reduce their overhead costs, heat exchangers are often the most attractive thermal management solutions. In the long run, upgrading to heat exchangers from traditional air conditioning units provides significant benefits. However, many of those benefits can be seen almost immediately after the change. The following are just two of the several ways in which heat exchangers can immediately reduce the costs of effective thermal management for virtually any application. (more…)

Designing the Most Efficient Thermal Management Solutions

If you compare heat exchangers to other options, like air conditioners or air compressors, it is obvious that heat exchangers are often the most efficient solution. However, when you compare heat exchangers to heat exchangers (such as air-to-air units and air-to-water units), the advantages of one design over another may not be immediately obvious. Choosing the most efficient thermal management solution depends on the specifics of any given application, such as operating requirements and the location where the application will be employed. (more…)

If you compare heat exchangers to other options, like air conditioners or air compressors, it is obvious that heat exchangers are often the most efficient solution. However, when you compare heat exchangers to heat exchangers (such as air-to-air units and air-to-water units), the advantages of one design over another may not be immediately obvious. Choosing the most efficient thermal management solution depends on the specifics of any given application, such as operating requirements and the location where the application will be employed. (more…)

When Ambient Heat Exchangers Work Best

Technology these days is a lot more resilient than it used to be. For instance, high-performance computers and manufacturing equipment often don’t need to be chilled in order to continue working properly. While overheating is still a serious concern, most modern electrical equipment can operate optimally in ambient temperatures. As long as they are safe from environmental contamination, electrical enclosures only need to be cooled enough to prevent heat pockets from forming near sensitive electrical equipment. Therefore, ambient heat exchangers work best for a wide variety of applications in an equally wide variety of industries. (more…)

Technology these days is a lot more resilient than it used to be. For instance, high-performance computers and manufacturing equipment often don’t need to be chilled in order to continue working properly. While overheating is still a serious concern, most modern electrical equipment can operate optimally in ambient temperatures. As long as they are safe from environmental contamination, electrical enclosures only need to be cooled enough to prevent heat pockets from forming near sensitive electrical equipment. Therefore, ambient heat exchangers work best for a wide variety of applications in an equally wide variety of industries. (more…)

More Efficient Cooling for Power Plants

Some industries may never interact with certain others, but power production is an industry that all others rely on. While power plants across the nation employ a variety of methods to produce and deliver power, they all rely on efficient thermal management solutions to ensure their continued operation. In many locations, those solutions come in the form of high-temperature heat exchangers. From cooling the electrical enclosures, bearings, and lubricants in generators to maintaining fluid temperatures during certain processes, Noren’s heat exchangers help ensure that power plants continue running smoothly. (more…)

Some industries may never interact with certain others, but power production is an industry that all others rely on. While power plants across the nation employ a variety of methods to produce and deliver power, they all rely on efficient thermal management solutions to ensure their continued operation. In many locations, those solutions come in the form of high-temperature heat exchangers. From cooling the electrical enclosures, bearings, and lubricants in generators to maintaining fluid temperatures during certain processes, Noren’s heat exchangers help ensure that power plants continue running smoothly. (more…)