One of the most well-known uses for modern heat exchangers is cooling electrical control panels in lieu of larger, more complicated air conditioning equipment. Like an automobile engine, electrical equipment gives off heat as it operates, and controlling that heat is vital to the equipment’s continued operation. With the ability to transfer heat, and even reutilize it for other purposes, when necessary, modern heat exchangers provide a myriad of benefits for companies that choose to employ them for their industrial thermal management needs. (more…)

One of the most well-known uses for modern heat exchangers is cooling electrical control panels in lieu of larger, more complicated air conditioning equipment. Like an automobile engine, electrical equipment gives off heat as it operates, and controlling that heat is vital to the equipment’s continued operation. With the ability to transfer heat, and even reutilize it for other purposes, when necessary, modern heat exchangers provide a myriad of benefits for companies that choose to employ them for their industrial thermal management needs. (more…)

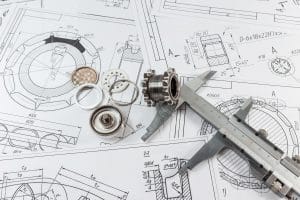

Is a Heat Exchanger Better when It’s Custom-Designed?

These days, thermal management solutions come in almost as many different forms, shapes, and sizes as the technology that relies on them. As industries continue to branch out and find new ways to implement advanced technology, they rely more heavily on innovative thermal management solutions to properly control electrical waste heat. To that end, some applications work best with heat exchangers that are custom-designed specifically for the application. In many cases, however, a unit that is already designed and certified may provide an equal level of efficiency and reliability. (more…)

These days, thermal management solutions come in almost as many different forms, shapes, and sizes as the technology that relies on them. As industries continue to branch out and find new ways to implement advanced technology, they rely more heavily on innovative thermal management solutions to properly control electrical waste heat. To that end, some applications work best with heat exchangers that are custom-designed specifically for the application. In many cases, however, a unit that is already designed and certified may provide an equal level of efficiency and reliability. (more…)

The Role of Technology in Reducing Medical Costs

Today’s medical facilities are stocked with devices and technology that most of us can’t even name. For hospitals, providers, and medical device companies, most of that technology is designed with as much focus on improving patient care as it is on controlling the skyrocketing costs of health care. From high-performance diagnostic devices to large, complex equipment, technology plays a significant role in reducing health care costs. Therefore, its performance can have profound implications, which is why more medical devices are being designed and implemented with Noren’s advanced thermal management technology. (more…)

Today’s medical facilities are stocked with devices and technology that most of us can’t even name. For hospitals, providers, and medical device companies, most of that technology is designed with as much focus on improving patient care as it is on controlling the skyrocketing costs of health care. From high-performance diagnostic devices to large, complex equipment, technology plays a significant role in reducing health care costs. Therefore, its performance can have profound implications, which is why more medical devices are being designed and implemented with Noren’s advanced thermal management technology. (more…)

Thermal Management – A Better Way to Go Green

These days, going green isn’t just about being environmentally responsible. It’s also about developing and implementing more affordable and sustainable solutions, especially for industries that rely on continuous operations. While there are many areas for companies to implement greener technology, thermal management is one of the most significant. With Noren’s advanced heat exchangers and other solutions, thermal management on all scales can become a focal point of any company’s green energy efforts. (more…)

These days, going green isn’t just about being environmentally responsible. It’s also about developing and implementing more affordable and sustainable solutions, especially for industries that rely on continuous operations. While there are many areas for companies to implement greener technology, thermal management is one of the most significant. With Noren’s advanced heat exchangers and other solutions, thermal management on all scales can become a focal point of any company’s green energy efforts. (more…)

How to Design the Best Thermal Management Solutions

At Noren Thermal, we’ve built a strong reputation for designing and improving thermal management solutions for virtually any application. Our highly skilled teams of technical and engineering experts work closely in tandem, and mostly in-house, to ensure that nothing is lost between a heat exchanger’s design and its performance in the field. In some cases, that means creating custom thermal management solutions during a given application’s design process. In others, though, it may mean thoroughly analyzing the proposed thermal management of an existing design, and then improving it to ensure it offers the most comprehensive results. (more…)

At Noren Thermal, we’ve built a strong reputation for designing and improving thermal management solutions for virtually any application. Our highly skilled teams of technical and engineering experts work closely in tandem, and mostly in-house, to ensure that nothing is lost between a heat exchanger’s design and its performance in the field. In some cases, that means creating custom thermal management solutions during a given application’s design process. In others, though, it may mean thoroughly analyzing the proposed thermal management of an existing design, and then improving it to ensure it offers the most comprehensive results. (more…)

Ecofriendly Food Packaging with the Help of Heat Exchangers

When it comes to our food, we tend to be more discerning about the products we buy than we are with other goods and services. Recent studies show that consumers pay increasingly more attention to how food is made and packaged. The majority of them prefer companies that offer eco-friendly products and packaging over those that do not. At Noren Thermal, efficiency and eco-friendliness have always been a driving factor behind the innovative thermal management solutions we provide. For our clients in the food packaging industry, our heat exchangers have helped streamline their efforts by providing custom, green energy thermal management solutions. (more…)

When it comes to our food, we tend to be more discerning about the products we buy than we are with other goods and services. Recent studies show that consumers pay increasingly more attention to how food is made and packaged. The majority of them prefer companies that offer eco-friendly products and packaging over those that do not. At Noren Thermal, efficiency and eco-friendliness have always been a driving factor behind the innovative thermal management solutions we provide. For our clients in the food packaging industry, our heat exchangers have helped streamline their efforts by providing custom, green energy thermal management solutions. (more…)

Safeguarding Heat Exchangers from Powder & Bulk

Contamination comes in many forms, depending on the industry. In the field of food and beverage manufacturing, for instance, powder and bulk solid foods like sugar, salt, and grains can pose a threat to sensitive thermal management equipment if it’s allowed to get through the equipment’s seals and gaskets. In other manufacturing fields, the biggest threats could be dirt, sawdust, or other hazardous materials constantly floating through the air. In all cases, however, heat exchangers are often ideal for protecting vital equipment from potentially dangerous powder and bulk contamination. (more…)

Contamination comes in many forms, depending on the industry. In the field of food and beverage manufacturing, for instance, powder and bulk solid foods like sugar, salt, and grains can pose a threat to sensitive thermal management equipment if it’s allowed to get through the equipment’s seals and gaskets. In other manufacturing fields, the biggest threats could be dirt, sawdust, or other hazardous materials constantly floating through the air. In all cases, however, heat exchangers are often ideal for protecting vital equipment from potentially dangerous powder and bulk contamination. (more…)

Making Molding More Efficient with Thermal Pins

The ability to effectively handle heat is an important aspect of all manufacturing operations. In most cases, it involves transferring waste heat to avoid damage to electrical equipment. In the molding industry, however, controlling and then rapidly dissipating heat is vital to the manufacturing process itself. With custom, high-performance thermal pins, Noren Thermal has helped clients throughout the molding industry increase the yields and improve the quality of their molds, all while reducing energy and maintenance costs. Thermal pins are specialized heat exchangers that are custom-designed specifically for the high-performance needs of the molding industry. (more…)

The ability to effectively handle heat is an important aspect of all manufacturing operations. In most cases, it involves transferring waste heat to avoid damage to electrical equipment. In the molding industry, however, controlling and then rapidly dissipating heat is vital to the manufacturing process itself. With custom, high-performance thermal pins, Noren Thermal has helped clients throughout the molding industry increase the yields and improve the quality of their molds, all while reducing energy and maintenance costs. Thermal pins are specialized heat exchangers that are custom-designed specifically for the high-performance needs of the molding industry. (more…)

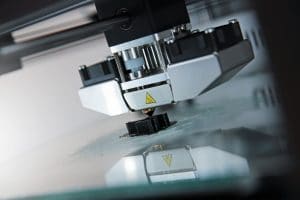

How Rapid Prototyping Makes Heat Exchangers More Efficient

Even with the most advanced design and manufacturing technology, not every product design translates flawlessly from paper to final product. For instance, sometimes, a part or product doesn’t quite fit as comfortably into a design’s limited space as the designer intended. Or, the wall of a heat exchanger may be closer to sensitive electrical equipment than designers realized. If a final product doesn’t fit the specifications it was designed for, then having to start over and produce all new units can be costly and time-consuming. With comprehensive feasibility studies and rapid 3D prototyping, we can detect and iron out issues that could halt production or affect a unit’s productivity, before the first unit is manufactured. (more…)

Even with the most advanced design and manufacturing technology, not every product design translates flawlessly from paper to final product. For instance, sometimes, a part or product doesn’t quite fit as comfortably into a design’s limited space as the designer intended. Or, the wall of a heat exchanger may be closer to sensitive electrical equipment than designers realized. If a final product doesn’t fit the specifications it was designed for, then having to start over and produce all new units can be costly and time-consuming. With comprehensive feasibility studies and rapid 3D prototyping, we can detect and iron out issues that could halt production or affect a unit’s productivity, before the first unit is manufactured. (more…)

Making Food & Beverage Processing Easier with Heat Exchangers

On farms across the country, technology has made planting, harvesting, and producing food a more effective and efficient process than ever. The same is true for the facilities that sort, store, and package these goods. With the advent of modern technology, these facilities can ensure that our food supplies stay fresh, healthy, and safe until they reach our tables. Heat exchangers play a major role in this shift. In addition to helping keep farm machinery and manufacturing equipment operating properly, heat exchangers are also responsible for making many of the processes required for food and beverage packaging much easier and more reliable. (more…)

On farms across the country, technology has made planting, harvesting, and producing food a more effective and efficient process than ever. The same is true for the facilities that sort, store, and package these goods. With the advent of modern technology, these facilities can ensure that our food supplies stay fresh, healthy, and safe until they reach our tables. Heat exchangers play a major role in this shift. In addition to helping keep farm machinery and manufacturing equipment operating properly, heat exchangers are also responsible for making many of the processes required for food and beverage packaging much easier and more reliable. (more…)