The ability to automate processes and repetitive procedures has been one of the biggest advantages of modern technology. In every industry, it’s proven valuable as both a time-saving endeavor and a cost-saving investment, helping companies streamline everything from administrative processes to assembly lines and more. The large-scale adoption and implementation of automated technologies has been possible due to several different, factors. While the streamlining of electrical thermal management with the help of heat exchangers has been only one of those factors, it’s been an essential one. They provide the high-performance cooling necessary for advanced applications in a manner that’s virtually automated itself. (more…)

The ability to automate processes and repetitive procedures has been one of the biggest advantages of modern technology. In every industry, it’s proven valuable as both a time-saving endeavor and a cost-saving investment, helping companies streamline everything from administrative processes to assembly lines and more. The large-scale adoption and implementation of automated technologies has been possible due to several different, factors. While the streamlining of electrical thermal management with the help of heat exchangers has been only one of those factors, it’s been an essential one. They provide the high-performance cooling necessary for advanced applications in a manner that’s virtually automated itself. (more…)

High Efficiency Ambient Cooling with Eco-Flow

One of the greatest advantages of modern thermal management systems is their ability to adapt to increasingly higher application demands while maintaining optimal efficiency. The new Eco-Flow heat dissipator is the epitome of that goal. Its dual filter fan design gives it the ability to match the standards and performance specifications of a wide range of electrical enclosures and can be utilized in several different configurations. (more…)

One of the greatest advantages of modern thermal management systems is their ability to adapt to increasingly higher application demands while maintaining optimal efficiency. The new Eco-Flow heat dissipator is the epitome of that goal. Its dual filter fan design gives it the ability to match the standards and performance specifications of a wide range of electrical enclosures and can be utilized in several different configurations. (more…)

Why Greener Companies Use Heat Exchangers

The idea of implementing more energy efficient and eco-friendly business practices has permeated most industries for decades now. It has prompted a wide range of initiatives, from carpooling and recycling to completely upgrading companies’ technology and equipment. While companies’ missions to make their operations greener has taken on many different forms, one of the most common has been revolutionizing their electrical cooling systems. Traditional solutions like air conditioners have been notorious for the amounts of energy they use and their inefficient operations. By upgrading their thermal management systems to more streamlined heat exchangers, companies have made significant strides in becoming greener and more eco-friendly businesses. (more…)

The idea of implementing more energy efficient and eco-friendly business practices has permeated most industries for decades now. It has prompted a wide range of initiatives, from carpooling and recycling to completely upgrading companies’ technology and equipment. While companies’ missions to make their operations greener has taken on many different forms, one of the most common has been revolutionizing their electrical cooling systems. Traditional solutions like air conditioners have been notorious for the amounts of energy they use and their inefficient operations. By upgrading their thermal management systems to more streamlined heat exchangers, companies have made significant strides in becoming greener and more eco-friendly businesses. (more…)

Designing Thermal Solutions that Work the First Time

Over the last several decades, heat exchangers have become popular electrical cooling solutions for several different reasons. On one hand, their performance speaks for itself, giving companies the ability to keep their technologies properly cooled at significantly lower costs and much higher efficiency. On the other hand, designing, creating, and implementing heat exchangers are also much more streamlined processes than they are with more traditional thermal management solutions. Together, their streamlined cooling functions and advanced manufacturing techniques make it easier to design heat exchangers for any given application, and ensure they work optimally the first time around. (more…)

Over the last several decades, heat exchangers have become popular electrical cooling solutions for several different reasons. On one hand, their performance speaks for itself, giving companies the ability to keep their technologies properly cooled at significantly lower costs and much higher efficiency. On the other hand, designing, creating, and implementing heat exchangers are also much more streamlined processes than they are with more traditional thermal management solutions. Together, their streamlined cooling functions and advanced manufacturing techniques make it easier to design heat exchangers for any given application, and ensure they work optimally the first time around. (more…)

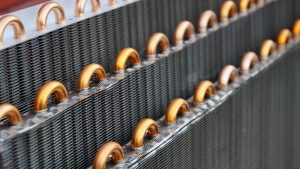

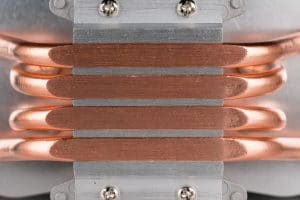

Heat Pipes as an Efficient Electrical Cooling System

These days, there are many different types of electrical cooling systems for companies and technology designers to choose from. The most frequently implemented solutions tend to be advanced heat exchangers that are able to handle varying levels of thermal management needs with optimal efficiency. For example, heat pipe heat exchangers, which are one of the most common types of heat exchangers, can be designed to keep large-scale equipment as efficiently cooled as smaller, high-performance electronics, and much more. In many cases, heat pipes can be the most beneficial choice in electrical cooling systems, and increasingly more technologies are benefiting from their high-performance cooling capabilities. (more…)

These days, there are many different types of electrical cooling systems for companies and technology designers to choose from. The most frequently implemented solutions tend to be advanced heat exchangers that are able to handle varying levels of thermal management needs with optimal efficiency. For example, heat pipe heat exchangers, which are one of the most common types of heat exchangers, can be designed to keep large-scale equipment as efficiently cooled as smaller, high-performance electronics, and much more. In many cases, heat pipes can be the most beneficial choice in electrical cooling systems, and increasingly more technologies are benefiting from their high-performance cooling capabilities. (more…)

Can Transferring Heat Really Make Cooling More Efficient?

Before heat exchangers and their ability to transfer waste heat revolutionized electrical cooling, the most common thermal management solutions followed the same basic principles. Using chilled air that’s generated through HVAC or air compression methods, these solutions forced the temperatures within electrical enclosures to remain well below maximum operating temperatures. As technology and electrical cooling have advanced, however, the trend hasn’t been to make chilling and circulating air in an enclosure more efficient. Instead, electrical thermal management has taken leaps forward by relying on more natural heat transfer methods that don’t rely on chilled air at all. (more…)

Before heat exchangers and their ability to transfer waste heat revolutionized electrical cooling, the most common thermal management solutions followed the same basic principles. Using chilled air that’s generated through HVAC or air compression methods, these solutions forced the temperatures within electrical enclosures to remain well below maximum operating temperatures. As technology and electrical cooling have advanced, however, the trend hasn’t been to make chilling and circulating air in an enclosure more efficient. Instead, electrical thermal management has taken leaps forward by relying on more natural heat transfer methods that don’t rely on chilled air at all. (more…)

The Relationship Between Heat Exchangers and Manufacturing

Since they first became a popular and well-known thermal management solution, heat exchangers have had an intricate relationship with the field of manufacturing. On one hand, their ability to streamline electrical cooling and other thermal management concerns have made them essential to modern manufacturing companies’ efficiency and productivity. On the other hand, as manufacturing has steadily advanced, heat exchanger manufacturers have gained important advantages in their ability to create and customize thermal solutions for increasingly more companies. In this relationship, heat exchangers and advanced manufacturing techniques have both evolved off of the advancements of the other. (more…)

Since they first became a popular and well-known thermal management solution, heat exchangers have had an intricate relationship with the field of manufacturing. On one hand, their ability to streamline electrical cooling and other thermal management concerns have made them essential to modern manufacturing companies’ efficiency and productivity. On the other hand, as manufacturing has steadily advanced, heat exchanger manufacturers have gained important advantages in their ability to create and customize thermal solutions for increasingly more companies. In this relationship, heat exchangers and advanced manufacturing techniques have both evolved off of the advancements of the other. (more…)

Reaching Below-Ambient Cooling without Chilled Air

Heat exchangers have become a significant part of thermal management processes across multiple different industries. That includes everything from electrical cooling, or the process of removing waste heat from inside of an electrical enclosure, to more challenging thermal processes such as wastewater treatment, and more. In some cases, the reason heat exchangers have become so popular is because they make ultimate use of ambient cooling techniques. However, in applications where ambient cooling isn’t enough, heat exchangers are becoming just as popular for their below-ambient thermal management capabilities. (more…)

Heat exchangers have become a significant part of thermal management processes across multiple different industries. That includes everything from electrical cooling, or the process of removing waste heat from inside of an electrical enclosure, to more challenging thermal processes such as wastewater treatment, and more. In some cases, the reason heat exchangers have become so popular is because they make ultimate use of ambient cooling techniques. However, in applications where ambient cooling isn’t enough, heat exchangers are becoming just as popular for their below-ambient thermal management capabilities. (more…)

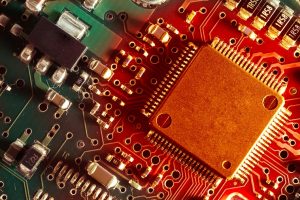

Liquid Cooling Made Easy – Heat Exchangers for Computers

For large-scale manufacturing technologies and equipment, heat exchangers have long been highly recognizable as an efficient and effective thermal management solution. Keeping such equipment properly cooled once took more cumbersome solutions, such as air conditioners. However, the significant energy and cost-savings heat exchangers provide proved invaluable to streamlining companies’ electrical cooling processes. Today, the same principles that made heat exchangers so valuable to larger equipment also make them highly beneficial for smaller, more powerful, and more advanced computing technologies. (more…)

For large-scale manufacturing technologies and equipment, heat exchangers have long been highly recognizable as an efficient and effective thermal management solution. Keeping such equipment properly cooled once took more cumbersome solutions, such as air conditioners. However, the significant energy and cost-savings heat exchangers provide proved invaluable to streamlining companies’ electrical cooling processes. Today, the same principles that made heat exchangers so valuable to larger equipment also make them highly beneficial for smaller, more powerful, and more advanced computing technologies. (more…)

How Companies Benefit from Custom Thermal Solutions

Among the many different advantages that come with modern heat exchangers, including lower electrical cooling costs and more efficient operations, one of the greatest benefits is the fact that heat exchangers are highly adaptable. This is largely due to their natural, highly efficient methods of transferring waste heat, which differ greatly from traditional methods that involve the use of chilled air. Transferring waste heat is a simpler and more efficient way of keeping electrical enclosures cooled, and also makes it easier to customize thermal solutions to meet companies’ unique thermal management needs. (more…)

Among the many different advantages that come with modern heat exchangers, including lower electrical cooling costs and more efficient operations, one of the greatest benefits is the fact that heat exchangers are highly adaptable. This is largely due to their natural, highly efficient methods of transferring waste heat, which differ greatly from traditional methods that involve the use of chilled air. Transferring waste heat is a simpler and more efficient way of keeping electrical enclosures cooled, and also makes it easier to customize thermal solutions to meet companies’ unique thermal management needs. (more…)