Despite the fact that effective waste heat management is vital to any technology, systems are often designed without proper consideration given to the application’s thermal management needs. Implementing a cooling solution is often left as an afterthought, and as a result, the application’s efficiency and reliability can suffer. The most effective way to ensure that any new system will operate at full capacity for as long as intended is to make sure that efficient thermal management is part of its design. For existing applications, customizable solutions such as heat exchangers can still offer optimal thermal management, thanks to their unique versatility. (more…)

Despite the fact that effective waste heat management is vital to any technology, systems are often designed without proper consideration given to the application’s thermal management needs. Implementing a cooling solution is often left as an afterthought, and as a result, the application’s efficiency and reliability can suffer. The most effective way to ensure that any new system will operate at full capacity for as long as intended is to make sure that efficient thermal management is part of its design. For existing applications, customizable solutions such as heat exchangers can still offer optimal thermal management, thanks to their unique versatility. (more…)

Using Heat Exchangers for Powder and Bulk Solid Foods

In the food and beverage industry, heat exchangers serve a variety of purposes, and their efficiency relies largely on their ability to keep electrical components safe from contaminants. When dealing with powder and bulk solid foods, this safety net has several implications, from maintaining the integrity of electrical and heat exchanger equipment to ensuring the safety of the foods being processed. Unlike other substances, powder and bulk foods pose several unique challenges, which heat exchangers are uniquely qualified to meet. (more…)

In the food and beverage industry, heat exchangers serve a variety of purposes, and their efficiency relies largely on their ability to keep electrical components safe from contaminants. When dealing with powder and bulk solid foods, this safety net has several implications, from maintaining the integrity of electrical and heat exchanger equipment to ensuring the safety of the foods being processed. Unlike other substances, powder and bulk foods pose several unique challenges, which heat exchangers are uniquely qualified to meet. (more…)

Common Applications for Below-Ambient Heat Exchangers

Ambient heat exchangers are like a constant breath of fresh air for modern electrical enclosures. Using natural/forced convection instead of air conditioning methods is as close as electrical components can get to operating in the fresh, open air instead of within an enclosure. Yet, many applications require cooling solutions that go below the ambient temperature outside of the enclosures. Others perform at such high capacities that they need below-ambient cooling to effectively prevent overheating. Today, we briefly examine a few of the common applications for below-ambient heat exchangers, and how they help streamline more demanding thermal management processes. (more…)

Ambient heat exchangers are like a constant breath of fresh air for modern electrical enclosures. Using natural/forced convection instead of air conditioning methods is as close as electrical components can get to operating in the fresh, open air instead of within an enclosure. Yet, many applications require cooling solutions that go below the ambient temperature outside of the enclosures. Others perform at such high capacities that they need below-ambient cooling to effectively prevent overheating. Today, we briefly examine a few of the common applications for below-ambient heat exchangers, and how they help streamline more demanding thermal management processes. (more…)

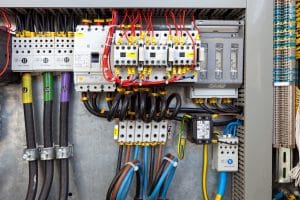

The Art of Cooling Electrical Enclosures

Electrical enclosures are a fact of life for any technological equipment. To manage them more easily, engineers and designers have found ways to make such enclosures increasingly smaller. However, this also poses several thermal management challenges, such as how to provide adequate cooling for more powerful equipment in smaller and tighter spaces. The need for efficient solutions to these challenges is what drove the adoption of modern heat exchangers. The art of constantly innovating thermal management technology is what keeps heat exchangers an important part of many advanced technologies. (more…)

Electrical enclosures are a fact of life for any technological equipment. To manage them more easily, engineers and designers have found ways to make such enclosures increasingly smaller. However, this also poses several thermal management challenges, such as how to provide adequate cooling for more powerful equipment in smaller and tighter spaces. The need for efficient solutions to these challenges is what drove the adoption of modern heat exchangers. The art of constantly innovating thermal management technology is what keeps heat exchangers an important part of many advanced technologies. (more…)

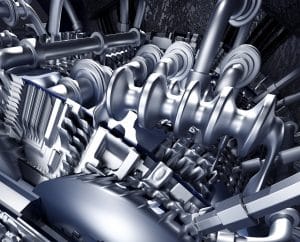

As Automated Technology Rises, So Does the Use of Heat Exchangers

When automated technology first became a reality, many industries feared that it would end up costing more than they could afford, or end up replacing large numbers of employees. It turns out, when implemented properly, automated technology is actually an enormous benefit to production and innovation in most companies, helping them grow their businesses at rates they previously thought impossible. Those benefits come from the ability to focus more time, energy, and resources on more productive tasks, and heat exchangers have allowed the technology to blossom by applying the same benefits to thermal management. (more…)

When automated technology first became a reality, many industries feared that it would end up costing more than they could afford, or end up replacing large numbers of employees. It turns out, when implemented properly, automated technology is actually an enormous benefit to production and innovation in most companies, helping them grow their businesses at rates they previously thought impossible. Those benefits come from the ability to focus more time, energy, and resources on more productive tasks, and heat exchangers have allowed the technology to blossom by applying the same benefits to thermal management. (more…)

Making Heat Exchangers Right the First Time

At Noren Thermal, our dedication to providing high-performance thermal management solutions goes beyond the high quality of products we provide. We’ve also invested significantly in providing accelerated and more precise design and manufacturing processes. In addition to wide-ranging expertise in thermal management, design, and engineering, we utilize advanced, in-house production technology, including 3D printing for rapid prototyping. Our goal is to make sure our clients receive the advanced solutions they need without losing time on hiccups during the design or production process. (more…)

At Noren Thermal, our dedication to providing high-performance thermal management solutions goes beyond the high quality of products we provide. We’ve also invested significantly in providing accelerated and more precise design and manufacturing processes. In addition to wide-ranging expertise in thermal management, design, and engineering, we utilize advanced, in-house production technology, including 3D printing for rapid prototyping. Our goal is to make sure our clients receive the advanced solutions they need without losing time on hiccups during the design or production process. (more…)

Reasons Why Heat Exchangers Contribute to Greener Energy

Effective thermal management means many things these days. However, in most applications, it requires high efficiency as much as low energy usage and consistent, reliable results. To achieve those goals, many industries rely on advanced ambient and below-ambient heat exchangers, which can achieve high-performance thermal management in a variety of energy-saving ways. At Noren, incorporating green energy concepts into every heat exchanger’s design allows us to provide effective, high-performance, and eco-friendly thermal management solutions for nearly every industry. (more…)

Effective thermal management means many things these days. However, in most applications, it requires high efficiency as much as low energy usage and consistent, reliable results. To achieve those goals, many industries rely on advanced ambient and below-ambient heat exchangers, which can achieve high-performance thermal management in a variety of energy-saving ways. At Noren, incorporating green energy concepts into every heat exchanger’s design allows us to provide effective, high-performance, and eco-friendly thermal management solutions for nearly every industry. (more…)

Why Aren’t Air Conditioners as Efficient as Heat Exchangers?

It wasn’t very long ago that air conditioning technology was the go-to solution for controlling the waste heat that electrical control panels and other enclosures emit. After all, keeping enclosures cool is exactly what air conditioners were designed to do. Today, there are still some applications in which air conditioning or air compressing technology is still the most effective thermal management solution. However, for the most part, air conditioners can no longer reach the levels of efficiency and efficacy that modern heat exchangers provide. (more…)

It wasn’t very long ago that air conditioning technology was the go-to solution for controlling the waste heat that electrical control panels and other enclosures emit. After all, keeping enclosures cool is exactly what air conditioners were designed to do. Today, there are still some applications in which air conditioning or air compressing technology is still the most effective thermal management solution. However, for the most part, air conditioners can no longer reach the levels of efficiency and efficacy that modern heat exchangers provide. (more…)

Helping Technology Meet Consumer and Industry Demands Equally

Among the greatest benefits of heat exchangers is that they free up space, time, and energy for other processes. For instance, without having to constantly maintain and repair air conditioning equipment or direct vast amounts of energy toward cooling electrical enclosures, manufacturers can redirect manpower and resources to more productive tasks. The more efficient use of space to transfer heat also provides a variety of other benefits, such as paving the way for more innovative consumer and industrial technology by simplifying the highly essential thermal management process. (more…)

Among the greatest benefits of heat exchangers is that they free up space, time, and energy for other processes. For instance, without having to constantly maintain and repair air conditioning equipment or direct vast amounts of energy toward cooling electrical enclosures, manufacturers can redirect manpower and resources to more productive tasks. The more efficient use of space to transfer heat also provides a variety of other benefits, such as paving the way for more innovative consumer and industrial technology by simplifying the highly essential thermal management process. (more…)

Food, Beverages, and Advanced Heat Exchangers

Safety and efficiency are what modern heat exchangers are known for. Along with a variety of other benefits, they’re also what often make them ideal for several applications in the food and beverage industry. For instance, when cooling control panels and manufacturing equipment, heat exchangers eliminate the risks of chemicals like Freon from entering the environment. When controlling the temperature for certain processes, heat exchangers allow for more reliable thermal management, and therefore, more reliable sanitizing procedures. (more…)

Safety and efficiency are what modern heat exchangers are known for. Along with a variety of other benefits, they’re also what often make them ideal for several applications in the food and beverage industry. For instance, when cooling control panels and manufacturing equipment, heat exchangers eliminate the risks of chemicals like Freon from entering the environment. When controlling the temperature for certain processes, heat exchangers allow for more reliable thermal management, and therefore, more reliable sanitizing procedures. (more…)