While modern heat exchangers have helped streamline thermal management and related processes in a variety of industries, those benefits have been significantly impactful to agriculture. Farming equipment, vehicles, and machinery are able to operate longer and more reliably with better thermal management. Food and beverage processing has become a more efficient endeavor, allowing companies across the industry to save significantly on energy consumption and costs. With the help of heat exchangers and other advanced solutions, modern thermal management has become much less of a burden to the agricultural industry. (more…)

While modern heat exchangers have helped streamline thermal management and related processes in a variety of industries, those benefits have been significantly impactful to agriculture. Farming equipment, vehicles, and machinery are able to operate longer and more reliably with better thermal management. Food and beverage processing has become a more efficient endeavor, allowing companies across the industry to save significantly on energy consumption and costs. With the help of heat exchangers and other advanced solutions, modern thermal management has become much less of a burden to the agricultural industry. (more…)

Noren’s Eco-Cool Heat Exchanger

For over 50 years, Noren Thermal has been dedicated to providing advanced thermal management solutions that help clients significantly improve their efficiency and productivity. Our commitment to continual innovation has helped us lead the way in advancing eco-friendly thermal management solutions, including our new line of Eco-Cool Heat Exchangers that can be used in a variety of applications. Thanks to its low energy consumption, the Eco-Cool Heat Exchanger boasts tremendous economical value for companies in all industries. (more…)

For over 50 years, Noren Thermal has been dedicated to providing advanced thermal management solutions that help clients significantly improve their efficiency and productivity. Our commitment to continual innovation has helped us lead the way in advancing eco-friendly thermal management solutions, including our new line of Eco-Cool Heat Exchangers that can be used in a variety of applications. Thanks to its low energy consumption, the Eco-Cool Heat Exchanger boasts tremendous economical value for companies in all industries. (more…)

Avoiding Mistakes that Can Hinder Thermal Management

What makes heat exchangers such an asset to so many industries is their ability to streamline thermal management to make it a much more efficient and eco-friendly process. Yet, minor mistakes in the design and manufacturing process can hinder their ability to work as effectively and reliably as it should. At Noren, maintaining a high level of quality in every product we make means avoiding such common mistakes so clients can enjoy more efficient thermal management without the headaches of correcting mistakes. (more…)

What makes heat exchangers such an asset to so many industries is their ability to streamline thermal management to make it a much more efficient and eco-friendly process. Yet, minor mistakes in the design and manufacturing process can hinder their ability to work as effectively and reliably as it should. At Noren, maintaining a high level of quality in every product we make means avoiding such common mistakes so clients can enjoy more efficient thermal management without the headaches of correcting mistakes. (more…)

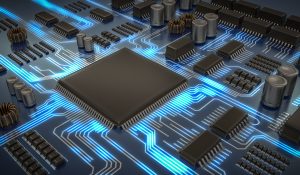

The Challenges of Cooling Modern Electronics

Over the last century, technology has advanced at an unprecedented rate, changing everything from manufacturing processes to how we communicate and interact with each other. The rapid pace at which electronics and computing technology has evolved has also changed the way technicians and engineers think about thermal management. Faster, smaller, and more powerful electronics emit more waste heat that must be properly managed. To keep up with these challenges, heat exchangers have evolved to provide the high-performance thermal management solutions needed to properly cool modern electronics. (more…)

Over the last century, technology has advanced at an unprecedented rate, changing everything from manufacturing processes to how we communicate and interact with each other. The rapid pace at which electronics and computing technology has evolved has also changed the way technicians and engineers think about thermal management. Faster, smaller, and more powerful electronics emit more waste heat that must be properly managed. To keep up with these challenges, heat exchangers have evolved to provide the high-performance thermal management solutions needed to properly cool modern electronics. (more…)

Want to Reduce Overhead? Start with Thermal Management

Companies in every industry can benefit from reducing overhead in ways that don’t negatively impact productivity. Most of those companies can also realize significant savings by analyzing and improving their electrical thermal management solutions. Instead of relying on more costly alternatives, like air conditioning, companies can effectively control electrical waste heat with more efficient heat exchangers. By implementing advanced heat exchanger technology, companies can more reliably cool high-performance technology and equipment at a fraction of the costs that come with air conditioning or air compressors. (more…)

Companies in every industry can benefit from reducing overhead in ways that don’t negatively impact productivity. Most of those companies can also realize significant savings by analyzing and improving their electrical thermal management solutions. Instead of relying on more costly alternatives, like air conditioning, companies can effectively control electrical waste heat with more efficient heat exchangers. By implementing advanced heat exchanger technology, companies can more reliably cool high-performance technology and equipment at a fraction of the costs that come with air conditioning or air compressors. (more…)

Modern Ways to Cool Electrical Control Panels

Electrical enclosures come in all shapes and sizes, and the thermal management solutions that cool them must be efficient and diverse enough to meet their unique specifications. For companies that rely on constantly running technology, particularly manufacturing, cooling various control panels is vital to their continued operations. At Noren, our specialty is providing clients with advanced thermal management solutions, such as ambient and below-ambient heat exchangers, to properly cool control panels of all sizes. (more…)

Electrical enclosures come in all shapes and sizes, and the thermal management solutions that cool them must be efficient and diverse enough to meet their unique specifications. For companies that rely on constantly running technology, particularly manufacturing, cooling various control panels is vital to their continued operations. At Noren, our specialty is providing clients with advanced thermal management solutions, such as ambient and below-ambient heat exchangers, to properly cool control panels of all sizes. (more…)

What Thermal Management Means for Wastewater Treatment

Treating wastewater effectively is an important part of many manufacturing processes. In municipal applications, it’s vital to sanitizing sewage to prevent the release of harmful substances into the environment. The same is true for industrial wastewater treatment, where different but equally or more harmful substances must be removed. In addition to cooling the technology responsible for most of wastewater treatment, thermal management is also an essential component to the process. Wastewater must be heated and treated with certain microorganisms that require specific temperatures to flourish. Heat exchangers can accomplish this more reliably while significantly reducing the need for natural gas for heating, and saving energy overall with more efficient thermal management methods. (more…)

Treating wastewater effectively is an important part of many manufacturing processes. In municipal applications, it’s vital to sanitizing sewage to prevent the release of harmful substances into the environment. The same is true for industrial wastewater treatment, where different but equally or more harmful substances must be removed. In addition to cooling the technology responsible for most of wastewater treatment, thermal management is also an essential component to the process. Wastewater must be heated and treated with certain microorganisms that require specific temperatures to flourish. Heat exchangers can accomplish this more reliably while significantly reducing the need for natural gas for heating, and saving energy overall with more efficient thermal management methods. (more…)

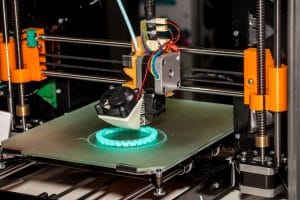

Why Rapid Prototyping Matters in Heat Exchanger Design

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product. (more…)

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product. (more…)

Thermal Pins – Heat Pipes for the Molding Industry

Heat exchanger technology has grown a reputation for changing the way industries think of thermal management. In some industries, harnessing and directing heat is required for more than just effectively cooling control panels and electrical enclosures. For instance, the molding industry operates on the principles of rapidly heating and cooling various materials. Because effective and reliable thermal management is directly involved in the molding process, a company’s choice in thermal management solutions directly affects its level of productivity and success. With the addition of thermal pins, molding companies can implement advanced heat pipe technology to the molding process, enjoying significant savings on energy while improving productivity and precision. (more…)

Heat exchanger technology has grown a reputation for changing the way industries think of thermal management. In some industries, harnessing and directing heat is required for more than just effectively cooling control panels and electrical enclosures. For instance, the molding industry operates on the principles of rapidly heating and cooling various materials. Because effective and reliable thermal management is directly involved in the molding process, a company’s choice in thermal management solutions directly affects its level of productivity and success. With the addition of thermal pins, molding companies can implement advanced heat pipe technology to the molding process, enjoying significant savings on energy while improving productivity and precision. (more…)

Common Uses for Cold Plate Heat Exchangers

Effective thermal management comes in a variety of forms these days, and in most cases, heat exchangers can be designed in equally various ways to achieve optimal results. Cold plate heat exchangers, for instance, can be designed for systems that require high effective heat transfer coefficients across large surfaces. Cold plates, which are usually crafted from metal and stacked together, can provide reliable, efficient, and highly effective thermal management solutions for high-performance operations. (more…)

Effective thermal management comes in a variety of forms these days, and in most cases, heat exchangers can be designed in equally various ways to achieve optimal results. Cold plate heat exchangers, for instance, can be designed for systems that require high effective heat transfer coefficients across large surfaces. Cold plates, which are usually crafted from metal and stacked together, can provide reliable, efficient, and highly effective thermal management solutions for high-performance operations. (more…)