Electrical enclosures are a fact of life for any technological equipment. To manage them more easily, engineers and designers have found ways to make such enclosures increasingly smaller. However, this also poses several thermal management challenges, such as how to provide adequate cooling for more powerful equipment in smaller and tighter spaces. The need for efficient solutions to these challenges is what drove the adoption of modern heat exchangers. The art of constantly innovating thermal management technology is what keeps heat exchangers an important part of many advanced technologies.

Electrical enclosures are a fact of life for any technological equipment. To manage them more easily, engineers and designers have found ways to make such enclosures increasingly smaller. However, this also poses several thermal management challenges, such as how to provide adequate cooling for more powerful equipment in smaller and tighter spaces. The need for efficient solutions to these challenges is what drove the adoption of modern heat exchangers. The art of constantly innovating thermal management technology is what keeps heat exchangers an important part of many advanced technologies.

Weighing Protection Against Thermal Management

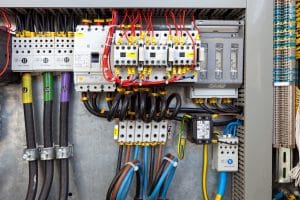

Electrical enclosures serve the vital function of protecting sensitive microprocessors and other electrical components from exposure to dust, moisture, and other damaging elements. They also create the need for consistent thermal management to stop waste heat from accumulating within the enclosure and inhibiting or damaging the equipment. This creates the dual needs of maintaining the integrity of an electrical enclosure’s seal while ensuring the continuous transfer of excess heat. Heat exchangers, which utilize natural heat transfer methods and high-quality seals and gaskets, are made specifically to meet these needs without taking up much space within a system’s design.

Designing Ways to Transfer or Use Waste Heat

Heat exchangers have evolved significantly over the last few decades, and today, they can serve an increasingly wider variety of applications. Companies in nearly every industry have utilized ambient and below-ambient heat exchangers to cool enclosures of all sizes, as well as to facilitate thermal management in other processes, such as wastewater treatment. Their versatility allows heat exchangers to meet challenges that more traditional solutions, including compressed air, cannot meet as effectively and efficiently.

To learn more, call Noren Thermal, Inc. in Taylor, TX, at 866-936-6736.