While improved productivity and lower overhead costs are significant factors in adopting new technology, eco-friendliness has become as important a consideration these days. On one hand, many regulations now mandate that companies take measures to reduce their environmental footprints. Otherwise, they may face massive fees in penalties. On another hand, today’s consumers also demand that the companies they do business with are more environmentally friendly than companies have been in the past. Together, these concerns have driven companies to race toward going green in both the products they provide and the manufacturing processes they employ. (more…)

While improved productivity and lower overhead costs are significant factors in adopting new technology, eco-friendliness has become as important a consideration these days. On one hand, many regulations now mandate that companies take measures to reduce their environmental footprints. Otherwise, they may face massive fees in penalties. On another hand, today’s consumers also demand that the companies they do business with are more environmentally friendly than companies have been in the past. Together, these concerns have driven companies to race toward going green in both the products they provide and the manufacturing processes they employ. (more…)

From Farm to Table – Heat Exchangers in Modern Agriculture

As one of the more vital industries, agriculture has long been one of the first to benefit from advanced manufacturing and other technologies, including advanced thermal management. In everything from farming equipment and dairy production to packaging and shipping operations, heat exchangers have helped virtually every part of the industry catch up to 21st century standards of safety, efficiency, and productivity. While this has greatly benefited the industry, it has also been of significant benefit to the communities that it supports across the country. (more…)

As one of the more vital industries, agriculture has long been one of the first to benefit from advanced manufacturing and other technologies, including advanced thermal management. In everything from farming equipment and dairy production to packaging and shipping operations, heat exchangers have helped virtually every part of the industry catch up to 21st century standards of safety, efficiency, and productivity. While this has greatly benefited the industry, it has also been of significant benefit to the communities that it supports across the country. (more…)

Things Every Company Should Know About Thermal Management

When air conditioners were the only option for electrical thermal management, companies didn’t think much about the costs and manpower they had to dedicate to maintaining them. That’s because preventing equipment from overheating is vital to a company’s continued operations. Without thermal management, the company’s equipment can’t run. Today, however, thermal management is a significant consideration, especially for companies that are looking for ways to lower operational costs, reduce their energy consumption, improve productivity, and lower their environmental footprints, all at the same time. (more…)

When air conditioners were the only option for electrical thermal management, companies didn’t think much about the costs and manpower they had to dedicate to maintaining them. That’s because preventing equipment from overheating is vital to a company’s continued operations. Without thermal management, the company’s equipment can’t run. Today, however, thermal management is a significant consideration, especially for companies that are looking for ways to lower operational costs, reduce their energy consumption, improve productivity, and lower their environmental footprints, all at the same time. (more…)

Do Heat Exchangers Help Consumers as Much as Companies?

For decades, companies in all industries have enjoyed enormous benefits thanks to the implementation of advanced heat exchangers. Lower energy costs, improved productivity, and more versatile thermal management solutions have allowed them to reinvest in more innovative technologies and expand their operations more cost effectively. However, heat exchangers have also helped improve the lives of everyday consumers by allowing for faster, more powerful products at affordable prices. In turn, companies that produce such products have added increased revenue and more competitive market positions to the many benefits that heat exchangers have provided them. (more…)

For decades, companies in all industries have enjoyed enormous benefits thanks to the implementation of advanced heat exchangers. Lower energy costs, improved productivity, and more versatile thermal management solutions have allowed them to reinvest in more innovative technologies and expand their operations more cost effectively. However, heat exchangers have also helped improve the lives of everyday consumers by allowing for faster, more powerful products at affordable prices. In turn, companies that produce such products have added increased revenue and more competitive market positions to the many benefits that heat exchangers have provided them. (more…)

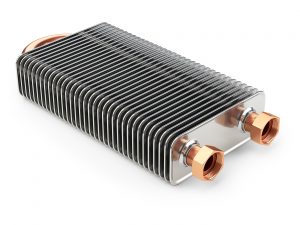

Comparing Heat Exchangers to Air Conditioners

These days, it’s common knowledge that heat exchangers typically provide a more efficient and reliable solution to thermal management than air conditioning. However, companies that are still debating whether or not they should make the change don’t always realize how heat exchangers accomplish this. Therefore, they don’t realize the many benefits that they’re missing out on. Today, we briefly compare the differences between how air conditioners and heat exchangers approach thermal management, and why the latter is generally the better option. (more…)

These days, it’s common knowledge that heat exchangers typically provide a more efficient and reliable solution to thermal management than air conditioning. However, companies that are still debating whether or not they should make the change don’t always realize how heat exchangers accomplish this. Therefore, they don’t realize the many benefits that they’re missing out on. Today, we briefly compare the differences between how air conditioners and heat exchangers approach thermal management, and why the latter is generally the better option. (more…)

Cooling Modern Electrical Cabinets

With so many advances in technology, especially in the manufacturing industry, streamlined thermal management can sometimes be overlooked. Compared to digital interfaces and automated technology, a sleeker and more efficient way to cool electrical cabinets doesn’t seem as attention-grabbing. However, such solutions are a significant reason why industries have been able to implement other technological advancements. All technology relies on efficient electrical thermal management, and heat exchangers allow companies to cool their modern electrical cabinets with optimal efficiency, minimal energy, and little or no maintenance. (more…)

With so many advances in technology, especially in the manufacturing industry, streamlined thermal management can sometimes be overlooked. Compared to digital interfaces and automated technology, a sleeker and more efficient way to cool electrical cabinets doesn’t seem as attention-grabbing. However, such solutions are a significant reason why industries have been able to implement other technological advancements. All technology relies on efficient electrical thermal management, and heat exchangers allow companies to cool their modern electrical cabinets with optimal efficiency, minimal energy, and little or no maintenance. (more…)

Can Heat Exchangers Really Meet NEMA Standards?

Efficiently transferring electrical waste heat is an essential benefit of modern heat exchangers. However, that benefit would be largely impossible if they couldn’t effectively meet the various NEMA standards that most electrical enclosures must meet these days. As industries continue to streamline productivity and safety, meeting these standards has become increasingly more important. Fortunately, today’s heat exchangers are designed specifically to maintain the integrity of different NEMA-class electrical enclosures. Using advanced heat transfer methods and high-quality seals and gaskets, heat exchangers can ensure a high level of safety under all types of operating conditions. (more…)

Efficiently transferring electrical waste heat is an essential benefit of modern heat exchangers. However, that benefit would be largely impossible if they couldn’t effectively meet the various NEMA standards that most electrical enclosures must meet these days. As industries continue to streamline productivity and safety, meeting these standards has become increasingly more important. Fortunately, today’s heat exchangers are designed specifically to maintain the integrity of different NEMA-class electrical enclosures. Using advanced heat transfer methods and high-quality seals and gaskets, heat exchangers can ensure a high level of safety under all types of operating conditions. (more…)

How Power Plants Benefit from Advanced Heat Exchangers

Most industries these days have largely benefited from advanced heat exchanger technology for their electrical thermal management needs. Among those benefits, the reduced need for energy and improved overall safety are two of the most important. Therefore, it’s no surprise that the field of power production is no exception. Plants across the world are increasingly utilizing efficient and eco-friendly heat exchanger technologies to power a variety of thermal management applications. The difference is that the benefits to power plants extend to the households and companies that rely on the power they produce. (more…)

Most industries these days have largely benefited from advanced heat exchanger technology for their electrical thermal management needs. Among those benefits, the reduced need for energy and improved overall safety are two of the most important. Therefore, it’s no surprise that the field of power production is no exception. Plants across the world are increasingly utilizing efficient and eco-friendly heat exchanger technologies to power a variety of thermal management applications. The difference is that the benefits to power plants extend to the households and companies that rely on the power they produce. (more…)

3 Ways Thermal Pins Improve Plastic Molds

Virtually all industries rely on the efficient and reliable transfer of heat, such as thermal management for electrical enclosures. Some, however, depend on that ability, such as the molding industry. Therefore, the implementation of advanced heat exchangers that can transfer high levels of heat with minimal energy requirements benefit such industries the most. For example, plastic and other molding facilities are increasingly turning to thermal pins to streamline their production process and lower overhead costs. Combining the advantages of advanced heat exchanger technology with the ability to fit nearly all types of molding equipment, thermal pins have significantly improved how plastic molding companies operate. (more…)

Virtually all industries rely on the efficient and reliable transfer of heat, such as thermal management for electrical enclosures. Some, however, depend on that ability, such as the molding industry. Therefore, the implementation of advanced heat exchangers that can transfer high levels of heat with minimal energy requirements benefit such industries the most. For example, plastic and other molding facilities are increasingly turning to thermal pins to streamline their production process and lower overhead costs. Combining the advantages of advanced heat exchanger technology with the ability to fit nearly all types of molding equipment, thermal pins have significantly improved how plastic molding companies operate. (more…)

Heat Exchangers: A Step in a Greener Direction

These days, one of the most important things for companies to focus on is finding ways to incorporate greener and more efficient processes. Besides regulations in some industries to ensure those efforts, consumers also prefer to do business with companies that are environmentally conscious with their products and manufacturing processes. In many cases, one of the most significant steps that companies in all industries can make is to upgrade their thermal management processes with the appropriate heat exchanger technology. As one of the most energy heavy processes, thermal management can be one of the biggest areas for companies to start getting serious about going green. (more…)

These days, one of the most important things for companies to focus on is finding ways to incorporate greener and more efficient processes. Besides regulations in some industries to ensure those efforts, consumers also prefer to do business with companies that are environmentally conscious with their products and manufacturing processes. In many cases, one of the most significant steps that companies in all industries can make is to upgrade their thermal management processes with the appropriate heat exchanger technology. As one of the most energy heavy processes, thermal management can be one of the biggest areas for companies to start getting serious about going green. (more…)