The search for greener, more manageable, and more eco-friendly ways to operate has become an important endeavor for companies in most industries, and for many reasons. On one hand, the general consensus is that companies need to be more responsible with their impacts on the environment and communities in which they’re situated. This means reducing pollution, cutting reliance on non-renewable energies, and implementing greener technological solutions wherever possible. In many cases, that includes revamping electrical thermal management systems with the help of modern, eco-friendly heat exchangers, which help streamline the process of electrical cooling in ways that make green energy efforts much easier. (more…)

The search for greener, more manageable, and more eco-friendly ways to operate has become an important endeavor for companies in most industries, and for many reasons. On one hand, the general consensus is that companies need to be more responsible with their impacts on the environment and communities in which they’re situated. This means reducing pollution, cutting reliance on non-renewable energies, and implementing greener technological solutions wherever possible. In many cases, that includes revamping electrical thermal management systems with the help of modern, eco-friendly heat exchangers, which help streamline the process of electrical cooling in ways that make green energy efforts much easier. (more…)

Questions and Answers About Modern Heat Exchangers

For companies that have already implemented advanced heat exchangers for their electrical thermal management needs, the advantages that have come with it seem obvious. Eliminating the need for solutions such as air conditioners and air compressors – the traditional answers to electrical cooling – has helped companies free up time, space, and capital, all while enhancing the efficiency of their thermal management systems. (more…)

For companies that have already implemented advanced heat exchangers for their electrical thermal management needs, the advantages that have come with it seem obvious. Eliminating the need for solutions such as air conditioners and air compressors – the traditional answers to electrical cooling – has helped companies free up time, space, and capital, all while enhancing the efficiency of their thermal management systems. (more…)

How Heat Exchangers Upgraded Electrical Cabinet Cooling

When companies begin thinking about technological advancement, their electrical thermal management processes may not always be at the top of the list. However, the methods that a company uses to keep their electrical cabinets, control panels, and other enclosures cooled plays a significant role in almost every area of operations. These days, companies in most industries rely on advanced, eco-friendly heat exchangers to meet their electrical enclosure cooling needs. In fact, thermal management remains further on the list of priorities for many companies because heat exchangers have already optimized the process for them. (more…)

When companies begin thinking about technological advancement, their electrical thermal management processes may not always be at the top of the list. However, the methods that a company uses to keep their electrical cabinets, control panels, and other enclosures cooled plays a significant role in almost every area of operations. These days, companies in most industries rely on advanced, eco-friendly heat exchangers to meet their electrical enclosure cooling needs. In fact, thermal management remains further on the list of priorities for many companies because heat exchangers have already optimized the process for them. (more…)

The Cost-Efficiency of Transferring Electrical Waste Heat

These days, electrical thermal management comes in many different forms. Often, the most effective and efficient method of handling electrical waste heat is to transfer it, which modern heat exchangers accomplish using a variety of natural thermal management methods. Compared to traditional cooling solutions, which most often focused on overwhelming waste heat with chilled and/or compressed air, the processes used by modern heat exchangers offer a wide range of benefits. One of the most notable of those is the cost-efficiency of transferring heat, rather than having to generate chilled air to stop it from causing damage. (more…)

These days, electrical thermal management comes in many different forms. Often, the most effective and efficient method of handling electrical waste heat is to transfer it, which modern heat exchangers accomplish using a variety of natural thermal management methods. Compared to traditional cooling solutions, which most often focused on overwhelming waste heat with chilled and/or compressed air, the processes used by modern heat exchangers offer a wide range of benefits. One of the most notable of those is the cost-efficiency of transferring heat, rather than having to generate chilled air to stop it from causing damage. (more…)

More Advanced Below-Ambient Electrical Cooling

In most areas of electrical thermal management, heat exchangers have proven more than adequate at helping companies optimize performance and efficiency. The ability to transfer waste heat makes them a more efficient and productive method of keeping electrical enclosures cooled than older methods, like air conditioning. However, not all heat exchangers were able to provide the below-ambient cooling that air conditioners are known for, and for some companies, that has meant relying on more costly conventional cooling solutions. Now, below-ambient heat exchangers are able to provide the same level of efficiency as regular ones for applications that require chilled temperatures for optimal performance. (more…)

In most areas of electrical thermal management, heat exchangers have proven more than adequate at helping companies optimize performance and efficiency. The ability to transfer waste heat makes them a more efficient and productive method of keeping electrical enclosures cooled than older methods, like air conditioning. However, not all heat exchangers were able to provide the below-ambient cooling that air conditioners are known for, and for some companies, that has meant relying on more costly conventional cooling solutions. Now, below-ambient heat exchangers are able to provide the same level of efficiency as regular ones for applications that require chilled temperatures for optimal performance. (more…)

A Glance at How Cold Plates Benefit Companies

Heat exchangers have evolved considerably since they first became popular in the realm of electrical thermal management. Today, companies have a wide range of options to choose from, including heat pipes or cold plates, each of which is designed to achieve optimal results according to the parameters of the applications for which their designed. For example, in many cases, cold plate heat exchangers offer the most effective and efficient cooling solution for several different reasons, including their ability to provide high-performance thermal management for a wide range of applications. (more…)

Heat exchangers have evolved considerably since they first became popular in the realm of electrical thermal management. Today, companies have a wide range of options to choose from, including heat pipes or cold plates, each of which is designed to achieve optimal results according to the parameters of the applications for which their designed. For example, in many cases, cold plate heat exchangers offer the most effective and efficient cooling solution for several different reasons, including their ability to provide high-performance thermal management for a wide range of applications. (more…)

The Ways Heat Exchangers Loop Electrical Cooling

When it comes to choosing the right electrical thermal management systems, companies have a wide range of concerns aside from achieving optimal efficiency. For example, companies have to weigh the costs of energy and maintenance that the system will require, as well as the level of protection that they solutions can provide against things like condensation and harmful contaminants. Part of the reason why heat exchangers have become such an increasingly more preferred solution is because they not only offer more efficient electrical cooling, but can also provide looped cooling apparatus that help optimize safety and protection, as well. (more…)

When it comes to choosing the right electrical thermal management systems, companies have a wide range of concerns aside from achieving optimal efficiency. For example, companies have to weigh the costs of energy and maintenance that the system will require, as well as the level of protection that they solutions can provide against things like condensation and harmful contaminants. Part of the reason why heat exchangers have become such an increasingly more preferred solution is because they not only offer more efficient electrical cooling, but can also provide looped cooling apparatus that help optimize safety and protection, as well. (more…)

Why Heat Exchangers Are Often the Right Cooling Solutions

The most notable advantage of heat exchangers is that they simplify the process of electrical thermal management. Compared to more traditional cooling solutions, they can deal with large amounts of waste heat quickly and efficiently, yet they do it using more streamlined and much less complicated methods. However, to achieve their notably high levels of performance and efficiency, modern heat exchangers are designed and manufactured in a more comprehensive and collaborative manner. Teams of thermal management, engineering, and other experts utilize several advanced design and manufacturing technologies to create heat exchangers or custom thermal solutions that outperform most other options for any given application. (more…)

The most notable advantage of heat exchangers is that they simplify the process of electrical thermal management. Compared to more traditional cooling solutions, they can deal with large amounts of waste heat quickly and efficiently, yet they do it using more streamlined and much less complicated methods. However, to achieve their notably high levels of performance and efficiency, modern heat exchangers are designed and manufactured in a more comprehensive and collaborative manner. Teams of thermal management, engineering, and other experts utilize several advanced design and manufacturing technologies to create heat exchangers or custom thermal solutions that outperform most other options for any given application. (more…)

Custom Thermal Solutions Benefit Food & Beverage Production

At first, heat exchangers were most important to the realm of thermal management because they helped companies save on the traditionally high costs of electrical cooling. However, before long, the possibilities that were unlocked by heat exchangers’ innovative heat transfer principles became obvious. Because the process of transferring heat is simpler, more efficient, and more manageable than conventional cooling methods, it has served as the basis for a wide range of custom thermal solutions. Many of them are designed specifically for particular industries, such as food and beverage production, and the unique thermal management needs that they entail. (more…)

At first, heat exchangers were most important to the realm of thermal management because they helped companies save on the traditionally high costs of electrical cooling. However, before long, the possibilities that were unlocked by heat exchangers’ innovative heat transfer principles became obvious. Because the process of transferring heat is simpler, more efficient, and more manageable than conventional cooling methods, it has served as the basis for a wide range of custom thermal solutions. Many of them are designed specifically for particular industries, such as food and beverage production, and the unique thermal management needs that they entail. (more…)

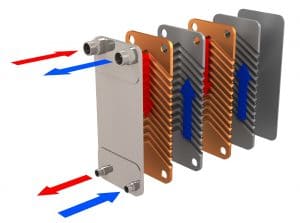

A Brief Look at the Benefits of Air-to-Water Heat Exchangers

Heat exchangers have long been an important part of many companies’ thermal management processes, and for many good reasons. However, before they became popular, industries first had to let go of several misconceptions they held about electrical thermal management. For example, it was once believed that the only way to effectively prevent an electrical enclosure from overheating is to keep the air inside of it chilled. Otherwise, the waste heat would quickly damage the components inside. As heat exchangers proved, this isn’t always he case, as the innovative thermal management solutions are designed to transfer electrical waste instead, using an eco-friendly cooling fluid to accomplish it. (more…)

Heat exchangers have long been an important part of many companies’ thermal management processes, and for many good reasons. However, before they became popular, industries first had to let go of several misconceptions they held about electrical thermal management. For example, it was once believed that the only way to effectively prevent an electrical enclosure from overheating is to keep the air inside of it chilled. Otherwise, the waste heat would quickly damage the components inside. As heat exchangers proved, this isn’t always he case, as the innovative thermal management solutions are designed to transfer electrical waste instead, using an eco-friendly cooling fluid to accomplish it. (more…)