These days, electrical thermal management comes in many different forms. Often, the most effective and efficient method of handling electrical waste heat is to transfer it, which modern heat exchangers accomplish using a variety of natural thermal management methods. Compared to traditional cooling solutions, which most often focused on overwhelming waste heat with chilled and/or compressed air, the processes used by modern heat exchangers offer a wide range of benefits. One of the most notable of those is the cost-efficiency of transferring heat, rather than having to generate chilled air to stop it from causing damage.

These days, electrical thermal management comes in many different forms. Often, the most effective and efficient method of handling electrical waste heat is to transfer it, which modern heat exchangers accomplish using a variety of natural thermal management methods. Compared to traditional cooling solutions, which most often focused on overwhelming waste heat with chilled and/or compressed air, the processes used by modern heat exchangers offer a wide range of benefits. One of the most notable of those is the cost-efficiency of transferring heat, rather than having to generate chilled air to stop it from causing damage.

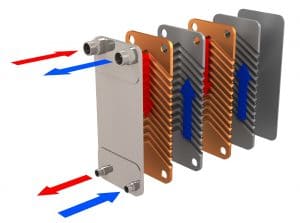

The heat transfer process in heat exchangers

The methods that heat exchangers use to transfer electrical waste heat are generally natural processes, such as natural/forced convection, conduction, phase-change cooling, or a combination of these methods. For example, a cooling fluid flows through the heat exchanger, which may be designed using heat pipes, cold plates, or more. As it absorbs the heat emitted by electrical components, the fluid evaporates and becomes less dense, then flows easily to a cooler area, such as a heat sink. Once it dissipates the heat, the fluid condenses back into a liquid and continues the cycle of absorbing and transferring heat.

A comparison to more traditional solutions

Though transferring heat is a simpler process compared to traditional cooling solutions, it’s highly advanced in several important ways. For instance, transferring heat can be accomplished with specialized heat pipes or cold plates and an eco-friendly cooling fluid, rather than complex HVAC equipment and harmful chemicals. This means they can effectively prevent electrical overheating with a higher degree of efficiency, but in a significantly more cost-effective manner. Without relying on HVAC techniques, heat exchangers can operate consistently with lower amounts of energy, and they don’t need frequent maintenance or repairs due to malfunctioning parts.

The cost and other benefits of electrical heat transfer

The ability to reduce energy needs for effective thermal management, coupled with the reduced need for maintenance and unexpected downtime, has made heat exchangers one of the most beneficial electrical cooling options for companies today. In addition to lowering costs, transferring heat is also a much more eco-friendly process, as well, making it easier for companies in all industries to lower their environmental footprints while minimizing the need to completely overhaul their technologies.

For more information about the cost-efficiency of transferring electrical waste heat, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.