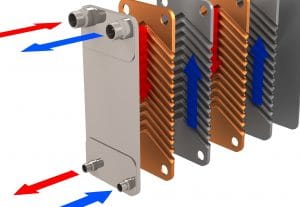

Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods. (more…)

Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods. (more…)

Using Heat Exchangers for More than Cooling Enclosures

For the application of cooling electrical enclosures, such as control panels, heat exchangers have excelled for decades. It isn’t just their reliability in consistently cooling such enclosures, but also the ability to do so with minimal energy, maintenance, and repair requirements. Given the many important benefits that they provide in electrical cooling, it’s only natural that the same efficient and eco-friendly heat transfer principles have led to thermal management innovations in areas beyond just keeping electrical enclosures cooled. Today, heat exchangers are commonly used for an increasingly wider variety of applications, which adds to their growing popularity across virtually every industry. (more…)

For the application of cooling electrical enclosures, such as control panels, heat exchangers have excelled for decades. It isn’t just their reliability in consistently cooling such enclosures, but also the ability to do so with minimal energy, maintenance, and repair requirements. Given the many important benefits that they provide in electrical cooling, it’s only natural that the same efficient and eco-friendly heat transfer principles have led to thermal management innovations in areas beyond just keeping electrical enclosures cooled. Today, heat exchangers are commonly used for an increasingly wider variety of applications, which adds to their growing popularity across virtually every industry. (more…)

Cooling Methods that Make Heat Exchangers Revolutionary

Sometimes, new technology makes an impact because it does something better than its currently existing counterparts. Sometimes, however, that innovation can be so impactful that it’s almost as though the new technology has completely revolutionized its respective field. Heat exchangers started off as the first example, providing a more efficient and cost-effective way for companies to consistently cool their technology and equipment. It turned out, however, that the innovation made possible thanks to the help of heat exchangers has had a much bigger impact than many people realized at first. That impact is due to the fact that heat exchangers improve thermal management not just by managing waste heat better than past alternatives, but by doing so in a simpler and more sustainable way than their predecessors. (more…)

Sometimes, new technology makes an impact because it does something better than its currently existing counterparts. Sometimes, however, that innovation can be so impactful that it’s almost as though the new technology has completely revolutionized its respective field. Heat exchangers started off as the first example, providing a more efficient and cost-effective way for companies to consistently cool their technology and equipment. It turned out, however, that the innovation made possible thanks to the help of heat exchangers has had a much bigger impact than many people realized at first. That impact is due to the fact that heat exchangers improve thermal management not just by managing waste heat better than past alternatives, but by doing so in a simpler and more sustainable way than their predecessors. (more…)

A Heat Exchanger for Nearly Every Industry

Most industries rely on similar types of technology, even if the specific applications for that technology can differ greatly. For example, automated technology can come in the form of software that streamlines a company’s administrative processes, or large equipment that makes up entire manufacturing assembly lines. Much like automation, most other forms of technology can be customized and applied as needed, but will always come with several consistent considerations for the companies that implement them. One of the most common of those considerations – and, also, one of the most impactful – is electrical thermal management, which heat exchangers can often address with optimal efficiency and reliability. (more…)

Most industries rely on similar types of technology, even if the specific applications for that technology can differ greatly. For example, automated technology can come in the form of software that streamlines a company’s administrative processes, or large equipment that makes up entire manufacturing assembly lines. Much like automation, most other forms of technology can be customized and applied as needed, but will always come with several consistent considerations for the companies that implement them. One of the most common of those considerations – and, also, one of the most impactful – is electrical thermal management, which heat exchangers can often address with optimal efficiency and reliability. (more…)

Important Considerations About Heat Pipes

There are several different types of heat exchangers that companies and technicians prefer according to any given system’s thermal management needs. In many cases, though, heat pipes are the most efficient method thanks to their many highly versatile applications. In everything from large manufacturing equipment and automated assembly lines to small, smart, and powerful consumer electronics, pipe-based heat exchangers offer the high-performance thermal management that most modern technologies rely on. (more…)

There are several different types of heat exchangers that companies and technicians prefer according to any given system’s thermal management needs. In many cases, though, heat pipes are the most efficient method thanks to their many highly versatile applications. In everything from large manufacturing equipment and automated assembly lines to small, smart, and powerful consumer electronics, pipe-based heat exchangers offer the high-performance thermal management that most modern technologies rely on. (more…)

The Benefit of Rapid Prototyping for Making Heat Exchangers

One of the most important reasons why heat exchangers have remained a prominent thermal management solution for so many different applications is because of their ability to meet increasingly more pressing demands. Even as technology continues advancing, heat exchangers and their many different iterations have effectively met their advanced thermal management demands. Part of that ability comes from a comprehensive, yet highly efficient, production process that includes the significant advantage of rapid 3D prototyping. (more…)

One of the most important reasons why heat exchangers have remained a prominent thermal management solution for so many different applications is because of their ability to meet increasingly more pressing demands. Even as technology continues advancing, heat exchangers and their many different iterations have effectively met their advanced thermal management demands. Part of that ability comes from a comprehensive, yet highly efficient, production process that includes the significant advantage of rapid 3D prototyping. (more…)

A Brief Look at Molding with Thermal Pins

Thermal management has many more applications than just electrical, and in some industries, those applications directly impact a company’s output and performance. For example, in the molding industry, thermal management doesn’t just mean keeping equipment cool, but also harnessing heat and rapidly removing it from molds during the production process. Much like more conventional electrical thermal management, the molding process itself can also be made much more efficient with the help of modern heat exchanger technology. Known as thermal pins, specialized heat exchangers allow companies to more effectively, efficiently, and evenly remove heat from their molds to significantly improve the rate and quality of their output. (more…)

Thermal management has many more applications than just electrical, and in some industries, those applications directly impact a company’s output and performance. For example, in the molding industry, thermal management doesn’t just mean keeping equipment cool, but also harnessing heat and rapidly removing it from molds during the production process. Much like more conventional electrical thermal management, the molding process itself can also be made much more efficient with the help of modern heat exchanger technology. Known as thermal pins, specialized heat exchangers allow companies to more effectively, efficiently, and evenly remove heat from their molds to significantly improve the rate and quality of their output. (more…)

How Heat Exchangers Meet Below-Ambient Cooling Needs

When heat exchangers first became popular, their ability to provide effective, efficient, and highly reliable thermal management was directly tied to their ambient cooling abilities. Instead of chilling an electrical enclosure, they prevented overheating by transferring the waste heat before it had a chance to accumulate. For most common applications, this proved more than viable. However, as technology continues advancing and companies continue expanding their reach and operating in new territories, the need for below-ambient cooling has become increasingly more pressing. Fortunately, below-ambient heat exchangers can meet that need with equal efficiency and reliability. (more…)

When heat exchangers first became popular, their ability to provide effective, efficient, and highly reliable thermal management was directly tied to their ambient cooling abilities. Instead of chilling an electrical enclosure, they prevented overheating by transferring the waste heat before it had a chance to accumulate. For most common applications, this proved more than viable. However, as technology continues advancing and companies continue expanding their reach and operating in new territories, the need for below-ambient cooling has become increasingly more pressing. Fortunately, below-ambient heat exchangers can meet that need with equal efficiency and reliability. (more…)

When Ambient Cooling Is All You Need

Not long ago, the idea of cooling electrical enclosures and other equipment to just above the ambient temperatures around them didn’t seem plausible. However, ever since heat exchangers became an increasingly more popular solution, the need for equipment such as air conditioners and other chilling methods have become less of a necessity. That’s because heat exchangers accomplish what didn’t seem possible before – the ability to keep electrical enclosures, control cabinets, and more properly cooled without having to chill the air within them. (more…)

Not long ago, the idea of cooling electrical enclosures and other equipment to just above the ambient temperatures around them didn’t seem plausible. However, ever since heat exchangers became an increasingly more popular solution, the need for equipment such as air conditioners and other chilling methods have become less of a necessity. That’s because heat exchangers accomplish what didn’t seem possible before – the ability to keep electrical enclosures, control cabinets, and more properly cooled without having to chill the air within them. (more…)

The Challenge of Thermal Management in Automated Tech

Over the last decade, automated technology has increasingly revolutionized the way companies in most industries operate. Everything from customer service, sales, and marketing to manufacturing, packaging, and shipping have all seen profound transformations thanks to the abilities that automated technologies have given companies. However, the transformation wasn’t easy, and the innovators of automation had to overcome several significant challenges before the technology could become so prominent. One of the greatest of those challenges was finding an efficient, eco-friendly, and nearly automated thermal management solution for handling the technology’s electrical waste heat – a challenge that is easily met with the help of modern heat exchangers. (more…)

Over the last decade, automated technology has increasingly revolutionized the way companies in most industries operate. Everything from customer service, sales, and marketing to manufacturing, packaging, and shipping have all seen profound transformations thanks to the abilities that automated technologies have given companies. However, the transformation wasn’t easy, and the innovators of automation had to overcome several significant challenges before the technology could become so prominent. One of the greatest of those challenges was finding an efficient, eco-friendly, and nearly automated thermal management solution for handling the technology’s electrical waste heat – a challenge that is easily met with the help of modern heat exchangers. (more…)