Noren’s innovative products are designed to meet the most demanding thermal management needs for a variety of industries. Consequently, some of the most demanding applications are based in equally demanding environments, such as for the oil and gas industry. In fact, Noren’s Hazloc line is the only line of heat exchangers that is certified for use in hazardous locations as per UL/cUL as well as ATEX and IECEx standards.

Noren’s innovative products are designed to meet the most demanding thermal management needs for a variety of industries. Consequently, some of the most demanding applications are based in equally demanding environments, such as for the oil and gas industry. In fact, Noren’s Hazloc line is the only line of heat exchangers that is certified for use in hazardous locations as per UL/cUL as well as ATEX and IECEx standards.

Meeting the Complex Demands of Innovative Technology

No matter how advanced modern technology becomes, it is seemingly impossible to reach 100 percent efficiency when it comes to thermal management. Even the most powerful and innovative electrical equipment gives off some amount of electrical waste heat. Because complex electronics must usually be sealed off from environmental contamination, electrical enclosures must effectively and efficiently transfer that heat to prevent extensive heat damage. With over four decades of experience customizing thermal management solutions for computers and complex machinery of all kinds, Noren is especially adept at meeting the complex thermal management demands of innovative technology. (more…)

No matter how advanced modern technology becomes, it is seemingly impossible to reach 100 percent efficiency when it comes to thermal management. Even the most powerful and innovative electrical equipment gives off some amount of electrical waste heat. Because complex electronics must usually be sealed off from environmental contamination, electrical enclosures must effectively and efficiently transfer that heat to prevent extensive heat damage. With over four decades of experience customizing thermal management solutions for computers and complex machinery of all kinds, Noren is especially adept at meeting the complex thermal management demands of innovative technology. (more…)

Do Heat Exchangers Really Outperform Air Conditioners?

Since the industrial revolution, industries have continuously sought ways to boost their productivity while finding ways to keep overhead costs reasonably low. In many instances, that has meant investing in ways to better manage the costs of energy consumption and routine maintenance on complex manufacturing equipment. For over 40 years, Noren Thermal has helped pioneer the drive to cleaner and more efficient thermal management solutions, utilizing a variety of heat exchanger models to suit the unique needs of every industry. As alternatives to air conditioning equipment that often proves costly to maintain, Noren’s heat exchangers offer a wide range of benefits, both immediately and long-term. (more…)

Since the industrial revolution, industries have continuously sought ways to boost their productivity while finding ways to keep overhead costs reasonably low. In many instances, that has meant investing in ways to better manage the costs of energy consumption and routine maintenance on complex manufacturing equipment. For over 40 years, Noren Thermal has helped pioneer the drive to cleaner and more efficient thermal management solutions, utilizing a variety of heat exchanger models to suit the unique needs of every industry. As alternatives to air conditioning equipment that often proves costly to maintain, Noren’s heat exchangers offer a wide range of benefits, both immediately and long-term. (more…)

A Closer Look at Phase-Change Cooling

Over the last several decades, thermal management has made leaps and bounds to keep up with the ever-evolving, higher-capacity advancement of electrical technology. In many instances, phase-change cooling has been one of the most significant breakthroughs. Heat exchangers that utilize phase-change technology rely on fluids with high thermal conductivity. When the fluid is near electrical components, it absorbs the waste heat and changes from liquid to gas. The fluid is moved to another part of the heat exchanger where it gives up the energy it absorbed and condenses back into a liquid, repeating the process continuously. (more…)

Over the last several decades, thermal management has made leaps and bounds to keep up with the ever-evolving, higher-capacity advancement of electrical technology. In many instances, phase-change cooling has been one of the most significant breakthroughs. Heat exchangers that utilize phase-change technology rely on fluids with high thermal conductivity. When the fluid is near electrical components, it absorbs the waste heat and changes from liquid to gas. The fluid is moved to another part of the heat exchanger where it gives up the energy it absorbed and condenses back into a liquid, repeating the process continuously. (more…)

Heat Exchangers Made Specifically for Powder & Bulk

In a variety of industries, from food manufacturing to pharmaceutical packaging and more, dealing with powder and bulk are a necessary part of operations. As such, sensitive electrical equipment and cooling technology must be properly protected from such miniscule, potentially harmful particles. If powder and bulk are allowed to enter an electrical cabinet, then the accumulation could lead to potentially serious damage, the need for costly repairs, and in some cases, significant downtime while systems are replaced. If the powder in question is a volatile substance, then that risk is expontentially higher. Fortunately, Noren’s advanced heat exchangers are highly adept at protecting electrical enclosures, even in areas that are highly prone to contamination from powder and bulk. (more…)

In a variety of industries, from food manufacturing to pharmaceutical packaging and more, dealing with powder and bulk are a necessary part of operations. As such, sensitive electrical equipment and cooling technology must be properly protected from such miniscule, potentially harmful particles. If powder and bulk are allowed to enter an electrical cabinet, then the accumulation could lead to potentially serious damage, the need for costly repairs, and in some cases, significant downtime while systems are replaced. If the powder in question is a volatile substance, then that risk is expontentially higher. Fortunately, Noren’s advanced heat exchangers are highly adept at protecting electrical enclosures, even in areas that are highly prone to contamination from powder and bulk. (more…)

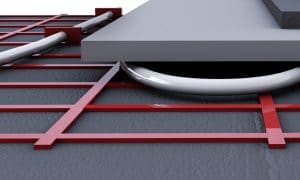

Thermal Pins Increase Yields for the Molding Industry

Thermal management is one of the most essential demands of the molding industry. The manufacturing process relies on superheating glass, plastic, metal, or ceramic so that it fits into the appropriate mold, then cooling the mold so that the material hardens. Cycle times depend on how fast and efficient the heating and cooling processes are, and overhead costs are significantly impacted by the energy used in each cycle. With Noren’s advanced thermal pins, companies can significantly increase their yields by drastically reducing cycle times and minimizing overall energy consumption. (more…)

Thermal management is one of the most essential demands of the molding industry. The manufacturing process relies on superheating glass, plastic, metal, or ceramic so that it fits into the appropriate mold, then cooling the mold so that the material hardens. Cycle times depend on how fast and efficient the heating and cooling processes are, and overhead costs are significantly impacted by the energy used in each cycle. With Noren’s advanced thermal pins, companies can significantly increase their yields by drastically reducing cycle times and minimizing overall energy consumption. (more…)

How Heat Exchangers Contribute to Greener Business

The push for cleaner and more sustainable energy resources is one of the largest and most important cross-industry initiatives in history. Typically, that push focuses on finding sources of energy other than fossil fuels, and implementing technology that has optimal functionality but leaves a minimal carbon footprint. One of the biggest challenges to implementing completely new machinery and operating systems is finding an equally efficient thermal management system to control the electrical waste heat that the systems give off. (more…)

The push for cleaner and more sustainable energy resources is one of the largest and most important cross-industry initiatives in history. Typically, that push focuses on finding sources of energy other than fossil fuels, and implementing technology that has optimal functionality but leaves a minimal carbon footprint. One of the biggest challenges to implementing completely new machinery and operating systems is finding an equally efficient thermal management system to control the electrical waste heat that the systems give off. (more…)

Why Heat Pipes May Be Your Most Efficient Thermal Management Option

Modern heat exchangers come in a variety of shapes, sizes, and types, each with its own unique advantages. For instance, heat pipes, which are among the most popular solutions, can be designed to optimize thermal management for virtually any system. While all heat spreaders are extremely effective at managing electrical waste heat, heat pipes offer significantly higher thermal conductivity than those that consist of solid conductors. Heat pipes are also more versatile in their design, making them able to fit into unique spaces to offer optimal results. (more…)

Modern heat exchangers come in a variety of shapes, sizes, and types, each with its own unique advantages. For instance, heat pipes, which are among the most popular solutions, can be designed to optimize thermal management for virtually any system. While all heat spreaders are extremely effective at managing electrical waste heat, heat pipes offer significantly higher thermal conductivity than those that consist of solid conductors. Heat pipes are also more versatile in their design, making them able to fit into unique spaces to offer optimal results. (more…)

Heat Exchangers for Processing and Packaging Pharmaceuticals

In addition to keeping manufacturing and other equipment properly cooled, thermal management is essential for a number of other applications in the pharmaceutical industry. Creating certain drugs and products must often be processed and/or stored at various, highly precise temperatures. The machinery used to process and package those substances also relies on thermal management solutions to prevent electrical circuits from overheating. The custom-design, minimal need for maintenance, and significant reduction in energy consumption make heat exchangers essential for a wide variety of processes, making them ideal for ensuring that operations run smoothly. (more…)

In addition to keeping manufacturing and other equipment properly cooled, thermal management is essential for a number of other applications in the pharmaceutical industry. Creating certain drugs and products must often be processed and/or stored at various, highly precise temperatures. The machinery used to process and package those substances also relies on thermal management solutions to prevent electrical circuits from overheating. The custom-design, minimal need for maintenance, and significant reduction in energy consumption make heat exchangers essential for a wide variety of processes, making them ideal for ensuring that operations run smoothly. (more…)

Efficient Thermal Management in Hazardous Locations

Industries that rely on manufacturing have benefited for decades by choosing heat exchanger technology to effectively manage waste heat from electrical enclosures. However, Noren’s innovative technology has helped organizations in far more industries enjoy the same benefits, and that technology was the first to be certified for use in hazardous locations. With this certification, more companies are able to take advantage of more efficient and less costly thermal management solutions, even in areas where heat exchangers weren’t always viable. (more…)

Industries that rely on manufacturing have benefited for decades by choosing heat exchanger technology to effectively manage waste heat from electrical enclosures. However, Noren’s innovative technology has helped organizations in far more industries enjoy the same benefits, and that technology was the first to be certified for use in hazardous locations. With this certification, more companies are able to take advantage of more efficient and less costly thermal management solutions, even in areas where heat exchangers weren’t always viable. (more…)