Companies in every industry can benefit from reducing overhead in ways that don’t negatively impact productivity. Most of those companies can also realize significant savings by analyzing and improving their electrical thermal management solutions. Instead of relying on more costly alternatives, like air conditioning, companies can effectively control electrical waste heat with more efficient heat exchangers. By implementing advanced heat exchanger technology, companies can more reliably cool high-performance technology and equipment at a fraction of the costs that come with air conditioning or air compressors. (more…)

Companies in every industry can benefit from reducing overhead in ways that don’t negatively impact productivity. Most of those companies can also realize significant savings by analyzing and improving their electrical thermal management solutions. Instead of relying on more costly alternatives, like air conditioning, companies can effectively control electrical waste heat with more efficient heat exchangers. By implementing advanced heat exchanger technology, companies can more reliably cool high-performance technology and equipment at a fraction of the costs that come with air conditioning or air compressors. (more…)

Modern Ways to Cool Electrical Control Panels

Electrical enclosures come in all shapes and sizes, and the thermal management solutions that cool them must be efficient and diverse enough to meet their unique specifications. For companies that rely on constantly running technology, particularly manufacturing, cooling various control panels is vital to their continued operations. At Noren, our specialty is providing clients with advanced thermal management solutions, such as ambient and below-ambient heat exchangers, to properly cool control panels of all sizes. (more…)

Electrical enclosures come in all shapes and sizes, and the thermal management solutions that cool them must be efficient and diverse enough to meet their unique specifications. For companies that rely on constantly running technology, particularly manufacturing, cooling various control panels is vital to their continued operations. At Noren, our specialty is providing clients with advanced thermal management solutions, such as ambient and below-ambient heat exchangers, to properly cool control panels of all sizes. (more…)

What Thermal Management Means for Wastewater Treatment

Treating wastewater effectively is an important part of many manufacturing processes. In municipal applications, it’s vital to sanitizing sewage to prevent the release of harmful substances into the environment. The same is true for industrial wastewater treatment, where different but equally or more harmful substances must be removed. In addition to cooling the technology responsible for most of wastewater treatment, thermal management is also an essential component to the process. Wastewater must be heated and treated with certain microorganisms that require specific temperatures to flourish. Heat exchangers can accomplish this more reliably while significantly reducing the need for natural gas for heating, and saving energy overall with more efficient thermal management methods. (more…)

Treating wastewater effectively is an important part of many manufacturing processes. In municipal applications, it’s vital to sanitizing sewage to prevent the release of harmful substances into the environment. The same is true for industrial wastewater treatment, where different but equally or more harmful substances must be removed. In addition to cooling the technology responsible for most of wastewater treatment, thermal management is also an essential component to the process. Wastewater must be heated and treated with certain microorganisms that require specific temperatures to flourish. Heat exchangers can accomplish this more reliably while significantly reducing the need for natural gas for heating, and saving energy overall with more efficient thermal management methods. (more…)

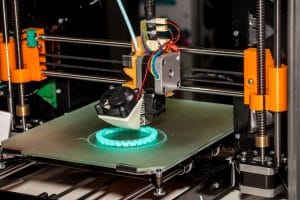

Why Rapid Prototyping Matters in Heat Exchanger Design

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product. (more…)

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product. (more…)

Thermal Pins – Heat Pipes for the Molding Industry

Heat exchanger technology has grown a reputation for changing the way industries think of thermal management. In some industries, harnessing and directing heat is required for more than just effectively cooling control panels and electrical enclosures. For instance, the molding industry operates on the principles of rapidly heating and cooling various materials. Because effective and reliable thermal management is directly involved in the molding process, a company’s choice in thermal management solutions directly affects its level of productivity and success. With the addition of thermal pins, molding companies can implement advanced heat pipe technology to the molding process, enjoying significant savings on energy while improving productivity and precision. (more…)

Heat exchanger technology has grown a reputation for changing the way industries think of thermal management. In some industries, harnessing and directing heat is required for more than just effectively cooling control panels and electrical enclosures. For instance, the molding industry operates on the principles of rapidly heating and cooling various materials. Because effective and reliable thermal management is directly involved in the molding process, a company’s choice in thermal management solutions directly affects its level of productivity and success. With the addition of thermal pins, molding companies can implement advanced heat pipe technology to the molding process, enjoying significant savings on energy while improving productivity and precision. (more…)

Common Uses for Cold Plate Heat Exchangers

Effective thermal management comes in a variety of forms these days, and in most cases, heat exchangers can be designed in equally various ways to achieve optimal results. Cold plate heat exchangers, for instance, can be designed for systems that require high effective heat transfer coefficients across large surfaces. Cold plates, which are usually crafted from metal and stacked together, can provide reliable, efficient, and highly effective thermal management solutions for high-performance operations. (more…)

Effective thermal management comes in a variety of forms these days, and in most cases, heat exchangers can be designed in equally various ways to achieve optimal results. Cold plate heat exchangers, for instance, can be designed for systems that require high effective heat transfer coefficients across large surfaces. Cold plates, which are usually crafted from metal and stacked together, can provide reliable, efficient, and highly effective thermal management solutions for high-performance operations. (more…)

Heat Exchangers’ Impact on the Manufacturing Industry

The goal to make manufacturing more efficient and cost-effective is not a new one. With the introduction of heat exchangers, however, that goal took on a new facet—the improvement of electrical thermal management. The continuous operation of manufacturing equipment is one of the biggest influencers on productivity, and the costs of keeping that equipment properly cooled can offer a significant area for improvement. With the help of heat exchangers, companies can significantly reduce those costs while also increasing overall productivity. (more…)

The goal to make manufacturing more efficient and cost-effective is not a new one. With the introduction of heat exchangers, however, that goal took on a new facet—the improvement of electrical thermal management. The continuous operation of manufacturing equipment is one of the biggest influencers on productivity, and the costs of keeping that equipment properly cooled can offer a significant area for improvement. With the help of heat exchangers, companies can significantly reduce those costs while also increasing overall productivity. (more…)

Computer Processing with the Help of Heat Exchangers

Leaders in a variety of industries have long recognized the value of advanced heat exchangers in providing highly efficient thermal management for industrial-sized electrical cabinets and control panels. Yet, electrical enclosures come in every shape and size, and are utilized for much more than just manufacturing equipment. For instance, today’s high-performance computers and consumer electronics rely on powerful processors that emit high levels of waste heat. For these devices to work properly, they also need highly efficient and reliable thermal management methods to effectively dissipate the excess heat. (more…)

Leaders in a variety of industries have long recognized the value of advanced heat exchangers in providing highly efficient thermal management for industrial-sized electrical cabinets and control panels. Yet, electrical enclosures come in every shape and size, and are utilized for much more than just manufacturing equipment. For instance, today’s high-performance computers and consumer electronics rely on powerful processors that emit high levels of waste heat. For these devices to work properly, they also need highly efficient and reliable thermal management methods to effectively dissipate the excess heat. (more…)

Why Heat Exchangers Should Be Part of Your Green Energy Efforts

In the not-too-distant past, the concept of wide-spread green energy solutions often seemed unattainable. However, the quest for greener technology and manufacturing processes has only grown at an exponential rate over the years. Today, companies throughout every industry have taken great strides to improve their operations through innovative, green energy equipment and processes. Often, those efforts include the implementation of heat exchangers to handle a wide variety of thermal management needs. (more…)

In the not-too-distant past, the concept of wide-spread green energy solutions often seemed unattainable. However, the quest for greener technology and manufacturing processes has only grown at an exponential rate over the years. Today, companies throughout every industry have taken great strides to improve their operations through innovative, green energy equipment and processes. Often, those efforts include the implementation of heat exchangers to handle a wide variety of thermal management needs. (more…)

Who Benefits from Heat Exchangers?

After proving themselves reliable for several decades, heat exchangers have become well-known for the numerous benefits they offer in the field of electrical thermal management. By helping companies eliminate their reliance on more costly measures, like air conditioning equipment or air compressors, heat exchangers are perhaps most well-known for their ability to reduce overall energy and maintenance costs. For many clients, heat exchangers also help streamline thermal management in numerous other areas, making them even more beneficial. (more…)

After proving themselves reliable for several decades, heat exchangers have become well-known for the numerous benefits they offer in the field of electrical thermal management. By helping companies eliminate their reliance on more costly measures, like air conditioning equipment or air compressors, heat exchangers are perhaps most well-known for their ability to reduce overall energy and maintenance costs. For many clients, heat exchangers also help streamline thermal management in numerous other areas, making them even more beneficial. (more…)