As the art (and the importance) of electrical thermal management has evolved, versatility and customization have become important aspect of modern heat exchanger technology. They’ve also become significant challenges – designing advanced thermal management technology is one thing, but ensuring that every innovative design performs as expected is another. Through comprehensive design, analysis, and feasibility testing, manufacturers can create increasingly more advanced heat exchanger designs while minimizing errors, reducing turn around times, and maximizing overall efficiency. (more…)

As the art (and the importance) of electrical thermal management has evolved, versatility and customization have become important aspect of modern heat exchanger technology. They’ve also become significant challenges – designing advanced thermal management technology is one thing, but ensuring that every innovative design performs as expected is another. Through comprehensive design, analysis, and feasibility testing, manufacturers can create increasingly more advanced heat exchanger designs while minimizing errors, reducing turn around times, and maximizing overall efficiency. (more…)

Manufacturing Made Easier with the Help of Heat Exchangers

The many different facets of technology have made it a defining characteristic of most modern societies. That includes virtually every industry that powers those societies, including all forms of manufacturing. Heat exchangers played a seemingly small role in the advancement of those technologies, but it’s a role that has proven to be pivotal. For example, at first, heat exchangers were simply used as an alternative electrical thermal management solution, allowing manufacturers to cut their reliance on more costly air conditioners. Now, however, modern heat exchangers and the science behind their thermal management processes have become key to several significant advanced forms of manufacturing technology. (more…)

The many different facets of technology have made it a defining characteristic of most modern societies. That includes virtually every industry that powers those societies, including all forms of manufacturing. Heat exchangers played a seemingly small role in the advancement of those technologies, but it’s a role that has proven to be pivotal. For example, at first, heat exchangers were simply used as an alternative electrical thermal management solution, allowing manufacturers to cut their reliance on more costly air conditioners. Now, however, modern heat exchangers and the science behind their thermal management processes have become key to several significant advanced forms of manufacturing technology. (more…)

3 Things Heat Exchangers Can Do that Air Conditioners Can’t

Some of the differences between heat exchangers and air conditioners are obvious, such as the reduced energy and overall costs that come with implementing the more streamlined thermal management solutions. However, the specific ways in which heat exchangers differ from more traditional solutions aren’t always as obvious. For example, the reason why they don’t require as much energy or as high of a cost to operate is because of the specific differences in how they approach electrical thermal management. (more…)

Some of the differences between heat exchangers and air conditioners are obvious, such as the reduced energy and overall costs that come with implementing the more streamlined thermal management solutions. However, the specific ways in which heat exchangers differ from more traditional solutions aren’t always as obvious. For example, the reason why they don’t require as much energy or as high of a cost to operate is because of the specific differences in how they approach electrical thermal management. (more…)

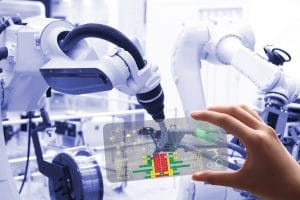

A Look at Heat Exchangers’ Contribution to Automation

The ability to make thermal management less of a burden and more of an advantage has made heat exchangers a truly disruptive force in virtually all industries. From manufacturing to agriculture and much more, more efficient electrical thermal management has also paved the way for increasingly more innovation in the form of advanced technologies. For example, thanks to being able to keep technology properly cooled with minimal interaction, minimal energy usage, and maximum reliability, heat exchangers have been an essential advantage in creating and implementing automated technology and machinery. (more…)

The ability to make thermal management less of a burden and more of an advantage has made heat exchangers a truly disruptive force in virtually all industries. From manufacturing to agriculture and much more, more efficient electrical thermal management has also paved the way for increasingly more innovation in the form of advanced technologies. For example, thanks to being able to keep technology properly cooled with minimal interaction, minimal energy usage, and maximum reliability, heat exchangers have been an essential advantage in creating and implementing automated technology and machinery. (more…)

3 Reasons Heat Exchangers Work for NEMA Enclosures

The National Electrical Manufacturers Association, or NEMA, regulates the various grades of electrical enclosures that are often utilized in manufacturing and other industrial applications. The point of the standards that NEMA sets forth is to maintain an optimal level of safety and functionality for electrical enclosures that often operate in hazardous conditions. For instance, adhering to the standards helps ensure an adequate degree of protection for personnel from accessing hazardous components of the enclosure and protection for the enclosure against certain environmental elements. Because of these high demands, heat exchangers are often the ideal solution for meeting these standards and ensuring optimal electrical thermal management for NEMA enclosures. (more…)

The National Electrical Manufacturers Association, or NEMA, regulates the various grades of electrical enclosures that are often utilized in manufacturing and other industrial applications. The point of the standards that NEMA sets forth is to maintain an optimal level of safety and functionality for electrical enclosures that often operate in hazardous conditions. For instance, adhering to the standards helps ensure an adequate degree of protection for personnel from accessing hazardous components of the enclosure and protection for the enclosure against certain environmental elements. Because of these high demands, heat exchangers are often the ideal solution for meeting these standards and ensuring optimal electrical thermal management for NEMA enclosures. (more…)

Extended Benefits of Better Thermal Management

The impact of thermal management can be felt in virtually every aspect of a company’s operations. From the reliability of their equipment to the level of energy the company consumes, better thermal management solutions equate to better, more reliable, and more efficient processes. However, the benefits of streamlining thermal management processes with the help of modern heat exchangers goes further than the operations contained within a facility’s four walls. From improving power production to optimizing pollution control measures such as wastewater treatment, communities as a whole have benefited, as well. (more…)

The impact of thermal management can be felt in virtually every aspect of a company’s operations. From the reliability of their equipment to the level of energy the company consumes, better thermal management solutions equate to better, more reliable, and more efficient processes. However, the benefits of streamlining thermal management processes with the help of modern heat exchangers goes further than the operations contained within a facility’s four walls. From improving power production to optimizing pollution control measures such as wastewater treatment, communities as a whole have benefited, as well. (more…)

How the Molding Industry Benefits from Heat Exchangers

These days, virtually every industry has benefited to some degree from the implementation of advanced heat exchangers. In any application that demands the use of advanced technology, the ability to apply high-performance electrical thermal management with minimal energy consumption and space requirements make heat exchangers the ideal cooling solution. In some industries, however, that ability is of more benefit than to others. For example, in the molding industry, efficient heat transfer is about more than just keeping electrical enclosures and equipment properly cooled. It’s also about optimizing a company’s output and productivity by creating a faster and more reliable way to remove the heat from each fresh mold. (more…)

These days, virtually every industry has benefited to some degree from the implementation of advanced heat exchangers. In any application that demands the use of advanced technology, the ability to apply high-performance electrical thermal management with minimal energy consumption and space requirements make heat exchangers the ideal cooling solution. In some industries, however, that ability is of more benefit than to others. For example, in the molding industry, efficient heat transfer is about more than just keeping electrical enclosures and equipment properly cooled. It’s also about optimizing a company’s output and productivity by creating a faster and more reliable way to remove the heat from each fresh mold. (more…)

What Makes Heat Exchangers So Attractive to Modern Companies

The fact that heat exchangers are popular isn’t the only reason why increasingly more companies are benefiting from the advent of heat exchangers. The main reason is because of the many different advantages that they experience thanks to the incredibly streamlined thermal management capabilities of modern heat exchangers. Designed to eliminate vast amounts of electrical waste heat using minimal amounts of energy and space, heat exchangers are often the most beneficial thermal management solutions to help companies stay competitive. (more…)

The fact that heat exchangers are popular isn’t the only reason why increasingly more companies are benefiting from the advent of heat exchangers. The main reason is because of the many different advantages that they experience thanks to the incredibly streamlined thermal management capabilities of modern heat exchangers. Designed to eliminate vast amounts of electrical waste heat using minimal amounts of energy and space, heat exchangers are often the most beneficial thermal management solutions to help companies stay competitive. (more…)

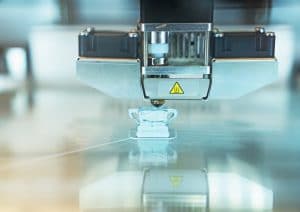

How 3D Printing Streamlines Heat Exchanger Manufacturing

As heat exchangers have advanced over the decades, they’ve taken on increasingly more roles in an ever-wider range of thermal management applications. That means manufacturers have learned to create an expansive range of heat exchanger types, each designed to accommodate the specific needs of certain, sometimes unique, applications. In the quest to continuously evolve their designs, heat exchanger manufacturers often employ advanced design and manufacturing techniques to ensure that every solution operates as designed. That often includes the use of 3D printing technology to create rapid prototypes that can be thoroughly tested before any unit goes into final production. (more…)

As heat exchangers have advanced over the decades, they’ve taken on increasingly more roles in an ever-wider range of thermal management applications. That means manufacturers have learned to create an expansive range of heat exchanger types, each designed to accommodate the specific needs of certain, sometimes unique, applications. In the quest to continuously evolve their designs, heat exchanger manufacturers often employ advanced design and manufacturing techniques to ensure that every solution operates as designed. That often includes the use of 3D printing technology to create rapid prototypes that can be thoroughly tested before any unit goes into final production. (more…)

Heat Exchanger Applications Besides Cooling Enclosures

Properly cooling electrical enclosures by eliminating the waste heat inside of them is a fundamental necessity. If any piece of equipment overheats, then it can malfunction and interrupt or completely stop a company’s operations. Given the importance of cooling electrical enclosures, that process has become one of the biggest reasons why heat exchangers have become prominent aspects of many companies’ operational infrastructure. However, these days, thermal management takes on may different forms in modern manufacturing and other operations. In many cases, heat exchangers also help vastly improve these applications, as well. (more…)

Properly cooling electrical enclosures by eliminating the waste heat inside of them is a fundamental necessity. If any piece of equipment overheats, then it can malfunction and interrupt or completely stop a company’s operations. Given the importance of cooling electrical enclosures, that process has become one of the biggest reasons why heat exchangers have become prominent aspects of many companies’ operational infrastructure. However, these days, thermal management takes on may different forms in modern manufacturing and other operations. In many cases, heat exchangers also help vastly improve these applications, as well. (more…)