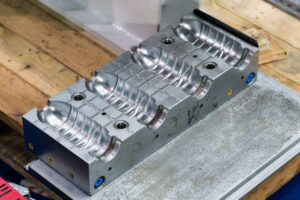

Last week, our team took a look at the ins and outs of heat sink thermal management, including the way these devices utilize thermal dissipation to provide an eco-friendly solution. Indeed, heat exchangers are excellent tools to help regulate internal temperatures within a technological application, and most are created without thermal solutions in mind, to begin with. Fortunately, our team manufactures a variety of solutions to help address your unique needs, including those of plastic molds. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the unique parameters of plastic mold cooling and how our solutions can address a variety of needs.

Last week, our team took a look at the ins and outs of heat sink thermal management, including the way these devices utilize thermal dissipation to provide an eco-friendly solution. Indeed, heat exchangers are excellent tools to help regulate internal temperatures within a technological application, and most are created without thermal solutions in mind, to begin with. Fortunately, our team manufactures a variety of solutions to help address your unique needs, including those of plastic molds. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the unique parameters of plastic mold cooling and how our solutions can address a variety of needs.

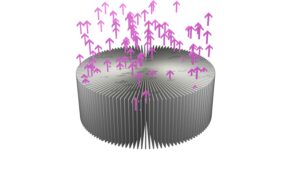

Looking At Heat Sink Thermal Management

For most industries, there are a few important goals or outcomes that define the business’ success. For example, completing timed executables in a timely and efficient manner could make all of the difference when it comes to the competition, just as it is necessary to keep the line up and running for food and beverage packaging. Indeed, there are several factors that go into the process, and unfortunately, overheating is one that affects most of them. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the major components of heat sink thermal management and describes how a custom heat exchanger can benefit you.

For most industries, there are a few important goals or outcomes that define the business’ success. For example, completing timed executables in a timely and efficient manner could make all of the difference when it comes to the competition, just as it is necessary to keep the line up and running for food and beverage packaging. Indeed, there are several factors that go into the process, and unfortunately, overheating is one that affects most of them. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains the major components of heat sink thermal management and describes how a custom heat exchanger can benefit you.

Complete Timed Executables Efficiently

Whether you are aware of it or not, the key to getting the most from your thermal solutions and industrial applications is seeking customized solutions. Indeed, many manufacturers tout the abilities of a one-size-fits-all heat exchanger to address your overheating needs, but this really only offers sub-optimal results, at best. When applying these concepts to specific industries, it becomes even more clear that the only way to optimize your capabilities is by seeking custom options. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains how a custom heat exchanger can be used to bring efficiency to your processes using automation.

Whether you are aware of it or not, the key to getting the most from your thermal solutions and industrial applications is seeking customized solutions. Indeed, many manufacturers tout the abilities of a one-size-fits-all heat exchanger to address your overheating needs, but this really only offers sub-optimal results, at best. When applying these concepts to specific industries, it becomes even more clear that the only way to optimize your capabilities is by seeking custom options. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains how a custom heat exchanger can be used to bring efficiency to your processes using automation.

Custom Solutions Benefit You

For years it has been clear that industry and advancing technology is the way to go when it comes to staying ahead of the curve in terms of competition. Indeed, virtually every industry nowadays has caught up to this standard, requiring the assistance of large-scale industrial applications to encourage greater outputs, yield, and shorter cycle times. Though many manufacturers may tout the abilities of one-size-fits-all heat exchanger, in all actuality, customization is key when it comes to getting the most from your devices. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the major benefits of seeking custom thermal solutions and how our team can help.

For years it has been clear that industry and advancing technology is the way to go when it comes to staying ahead of the curve in terms of competition. Indeed, virtually every industry nowadays has caught up to this standard, requiring the assistance of large-scale industrial applications to encourage greater outputs, yield, and shorter cycle times. Though many manufacturers may tout the abilities of one-size-fits-all heat exchanger, in all actuality, customization is key when it comes to getting the most from your devices. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the major benefits of seeking custom thermal solutions and how our team can help.

Major Concepts That Drive Our Designs

In our most recent blog, we took a look at the components needed for thermal success, as well as what it meant to practice sustainable thermal management. Indeed, your industrial applications may be able to help you achieve a host of great capabilities, however, if you do not factor in the potential to overheat, you will quickly find yourself in a difficult predicament. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX continues this discussion on important factors that are considered when looking for thermal solutions and identifies a few of the major concepts that drive our thermal solutions.

In our most recent blog, we took a look at the components needed for thermal success, as well as what it meant to practice sustainable thermal management. Indeed, your industrial applications may be able to help you achieve a host of great capabilities, however, if you do not factor in the potential to overheat, you will quickly find yourself in a difficult predicament. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX continues this discussion on important factors that are considered when looking for thermal solutions and identifies a few of the major concepts that drive our thermal solutions.

Components Needed For Thermal Success

For over fifty years, our team has utilized collaborative engineering and our years of expertise to help you find the ideal thermal solution that is needed for your specific needs. Indeed, thermal management is an essential process that helps prevent overheating in industrial applications, but what exactly does this mean, and how exactly does it all work? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the many components we use to promote optimal thermal management and explains how each method could benefit specific industries and businesses.

For over fifty years, our team has utilized collaborative engineering and our years of expertise to help you find the ideal thermal solution that is needed for your specific needs. Indeed, thermal management is an essential process that helps prevent overheating in industrial applications, but what exactly does this mean, and how exactly does it all work? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the many components we use to promote optimal thermal management and explains how each method could benefit specific industries and businesses.

Helping You Find Your Ideal Solution

It goes without saying that technological advancement has certainly paved the way for greater capabilities in a host of different industries. For example, industrial-grade applications can be used to promote higher yields at lower cycle times for certain fields, as well as assist in resource extraction at greater levels of success. Indeed, technology has made it possible to achieve even greater capabilities than ever before, but it is also important to recognize that even these devices may have limits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains how we can help you find your ideal thermal solution and how we assist throughout the process.

It goes without saying that technological advancement has certainly paved the way for greater capabilities in a host of different industries. For example, industrial-grade applications can be used to promote higher yields at lower cycle times for certain fields, as well as assist in resource extraction at greater levels of success. Indeed, technology has made it possible to achieve even greater capabilities than ever before, but it is also important to recognize that even these devices may have limits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explains how we can help you find your ideal thermal solution and how we assist throughout the process.

Phase-Change Methods For Heat Pipes

In our most recent blog post, we took a look at the way heat exchangers such as heat sinks utilized thermal dissipation in order to prevent overheating within a given application. Indeed, the methods with which you regulate waste heat production in your environment matters tremendously, as not all options can optimize everyone’s capabilities. Still, however, it is beneficial to understand the differences between methods so you can have a good idea of where to start. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind phase-change technology, as well as how it is used within heat pipe heat exchangers.

In our most recent blog post, we took a look at the way heat exchangers such as heat sinks utilized thermal dissipation in order to prevent overheating within a given application. Indeed, the methods with which you regulate waste heat production in your environment matters tremendously, as not all options can optimize everyone’s capabilities. Still, however, it is beneficial to understand the differences between methods so you can have a good idea of where to start. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind phase-change technology, as well as how it is used within heat pipe heat exchangers.

The Science Behind Thermal Dissipation

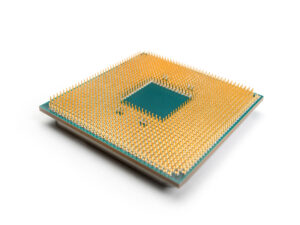

Technological advancements have made it possible for various industries to accomplish even more than they initially sought out to do. Indeed, we as a society rely heavily on technology to help us get the job done, whatever that job may be. From computer and printing equipment in an office to power lines and telephone poles, virtually every line of work benefits from technology. Unfortunately, overheating is a threat to most applications, and a heat exchanger is often needed to prevent this from occurring. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the importance of thermal regulation and discusses the science behind thermal dissipation.

Technological advancements have made it possible for various industries to accomplish even more than they initially sought out to do. Indeed, we as a society rely heavily on technology to help us get the job done, whatever that job may be. From computer and printing equipment in an office to power lines and telephone poles, virtually every line of work benefits from technology. Unfortunately, overheating is a threat to most applications, and a heat exchanger is often needed to prevent this from occurring. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the importance of thermal regulation and discusses the science behind thermal dissipation.

Addressing Cooling In Hydraulics

It goes without saying that technological advancement has paved the way for greater thermal capabilities, allowing manufacturers to address overheating before it becomes an issue. Indeed, advances in these capabilities not only addressed the issue of thermal management, but it allowed companies to effectively get the most from their setups, yielding greater outcomes and profits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the importance of functional safety when using industrial applications, as well as how our custom solutions can provide optimal hydraulic cooling.

It goes without saying that technological advancement has paved the way for greater thermal capabilities, allowing manufacturers to address overheating before it becomes an issue. Indeed, advances in these capabilities not only addressed the issue of thermal management, but it allowed companies to effectively get the most from their setups, yielding greater outcomes and profits. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the importance of functional safety when using industrial applications, as well as how our custom solutions can provide optimal hydraulic cooling.