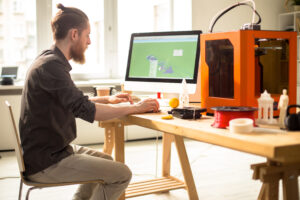

3D printing is quickly becoming a dominating force in the manufacturing landscape. This process is more precisely known by the term additive manufacturing. When the involved machinery is running efficiently, this can be a revolutionary new way for small-scale producers to develop prototypes in record time. Engineers are designing more and more applications for this technology each day. New materials such as ceramic clay allow for the creation of printed designs. Even food is bring used as a medium for 3D printing technology!

3D printing is quickly becoming a dominating force in the manufacturing landscape. This process is more precisely known by the term additive manufacturing. When the involved machinery is running efficiently, this can be a revolutionary new way for small-scale producers to develop prototypes in record time. Engineers are designing more and more applications for this technology each day. New materials such as ceramic clay allow for the creation of printed designs. Even food is bring used as a medium for 3D printing technology!

With such sophisticated computer science, the proper thermal maintenance is paramount in ensuring that you can produce efficiently and consistently. Production halts can be disproportionately costly with this method, so the key to a successful operation is keeping your machinery and its components running safely in avoiding overheating. Increased heat can also lead to increases in waste, so it is crucial to avoid these inefficiencies through proper thermal management. At Noren Thermal Solutions in Taylor, TX, we are dedicated to helping small businesses like yours bring creation and design into the new millennium with 3d printing. Discover how an efficient system can help your additive manufacturing system, from one printer to an entire farm!

Specific Hazards For Additive Manufacturing

While 3D printing is becoming more and more popular, it has only become recently common. There are individual concerns that relate to this method that do not exist in others. Efficiency has grown over the last decade in its thermal management almost as much as the production method itself.

For your specific needs, it may be best to discuss your solution with our team so that we can help you grow into the future. If you are planning on expanding the amount of your machines, you may look toward a solution that can help you scale.

The Benefits Of Copper Heat Sinks

One of the ways that we strive to give you the most stable experience in production is our choice of heat sink metal. While other companies rely on aluminum, copper is two to three times as efficient in its heat transfer capabilities. This allows your system to create less waste and captures more heat from your computing technology.

Reduce component strain as well and work to ensure that your machines operate with longevity. By maintaining your machinery, you can help to maximize profitability and further grow your small business!

Printing Toward The Future With Noren Thermal Solutions

At Noren Thermal Solutions in Taylor, TX, we applaud the innovators that are bringing additive manufacturing to the forefront of production. Enhance your creativity by spending less time on your machinery and more time designing. Give us a call at 512-595-5700 to learn more about how we can help you to create bigger and bolder new projects!