Determining the most appropriate method for thermal management within your applications largely depends on your unique parameters. Indeed, a custom heat exchanger such as a heat sink may do well for applications aiming to utilize dissipation, but this is not the case for a variety of industries. Further, these methods may not offer as much optimization as a group might expect, leading to more complications than it does solutions. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the overwhelming need for electrical panel enclosure cooling, and how our team can provide custom products that address your needs.

Determining the most appropriate method for thermal management within your applications largely depends on your unique parameters. Indeed, a custom heat exchanger such as a heat sink may do well for applications aiming to utilize dissipation, but this is not the case for a variety of industries. Further, these methods may not offer as much optimization as a group might expect, leading to more complications than it does solutions. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the overwhelming need for electrical panel enclosure cooling, and how our team can provide custom products that address your needs.

The Need for Electrical Panel Enclosure Cooling

It goes without saying that a number of businesses utilize technology to streamline the production process. As a matter of fact, many industries rely heavily on their devices to maintain their position in competitive fields, which means consistency of function is essential to establish. Although this is the goal, many applications are not capable of consistent function without additional accessories. Fortunately, electrical panel enclosure cooling can help tremendously.

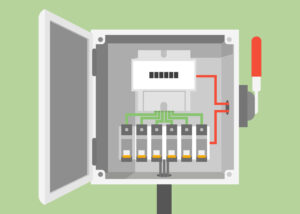

For a variety of applications, the central point of function is considered to be housed in the electrical panel or enclosure. In other words, the sensitive electronics and wires necessary to maintain function are housed in a central location, oftentimes with an air-tight seal to protect against outside debris. The problem arises, however, when these components begin to generate heat and cause the internal temperature of the breaker box to increase.

Indeed, without an effective method for ridding the enclosure of this surmounting waste heat, the internal temperatures can reach dangerous levels and cause significant damage to your equipment. In cases such as these, it is important to consider a thermal management option. To learn more about this process, give our team a call today.

A Central Breaker Box

Although it would be foolish to leave wires and components exposed that are integral to your operation, having them all enclosed within a confine and without a method for temperature regulation will only lead to issues as well.

Indeed, your central breaker box should be able to provide an air-tight seal that keeps out debris, as well as a method for temperature regulation to prevent overheating, and our team is ready to help. Contact one of our representatives to learn about your options today.

Maintaining Consistent Protection

Your equipment is integral to staying ahead of the competitive curve, and you should not have to break the bank just to ensure consistency in operation and quality. Our team will work with you to determine a thermal solution that best meets your needs through consideration of each of your parameters.

Learn More Today

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to learn how you can upgrade your thermal capabilities in order to provide optimal levels of thermal management and consistent function.