Effective temperature regulation and disposal of thermal waste within a given application is a necessary step to accomplish if you are relying on heavy machinery to accomplish a task. Indeed, a number of industries have made the move from air-to-air management to custom products that maximize the function of their applications, and our team is here to assist. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the management concept of dissipation, and how a heat sink can promote effective enclosure cooling.

Effective temperature regulation and disposal of thermal waste within a given application is a necessary step to accomplish if you are relying on heavy machinery to accomplish a task. Indeed, a number of industries have made the move from air-to-air management to custom products that maximize the function of their applications, and our team is here to assist. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the management concept of dissipation, and how a heat sink can promote effective enclosure cooling.

Preventing Overheating

As the inner mechanisms of an application mechanically work together to produce a product or perform a task, thermal energy is generated. If an application is designed without a means for removing this heat, it will continue to build and build. This not only causes the internal temperature of a machine to rise drastically, but will eventually result in overheating and even significant damage of the equipment. Indeed, significant cost has been attributed to mechanism maintenance and equipment replacement in the past, causing significant economic stress for a business’ output as well as upkeep.

To avoid the negative effects of overheating, an application must either be created with a means of regulating temperature or obtain a solution or accessory that can accomplish this feat. Fortunately, this is where our team comes in to help by utilizing eco-friendly and naturally occurring thermal management concepts to accomplish this task.

Dissipating Heat Waste

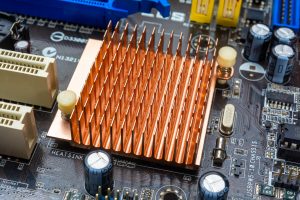

We implement three strategies to handle thermal waste – spreading, movement, and dissipation. Our heat sink solutions utilize the strategy of spreading to rapidly disperse the waste into the surrounding air, and can do so through forced air cooling. Our team recognizes that power densities per square inch are forever increasing as space allotted for these products continues to reduce. As a solution to this dilemma, our custom cooper-finned heat sinks spread or dissipate waste quickly and efficiently.

Copper contains a thermal transfer rate of nearly double that of aluminum, meaning the use of this material can do wonders for proper heat sink enclosure cooling. For more information about this process, reach out to your Noren representative today.

Optimal Cooling Capabilities

It is one thing to cool sensitive technology and prevent overheating, but it is completely different to do so in a manner that is also optimal and efficient. Our team takes the time to work with you and gain a thorough understanding of the specific parameters your applications have that need to be met. What’s more, we continue to innovate and strive to create optimally-functioning solutions with eco-friendly concepts.

Speak with Our Team

For more information about optimal heat sink enclosure cooling, reach out to the team at Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative and get started on your custom solution.