By now, the fact that heat exchangers make electrical thermal management much more efficient is well-known. In most industries, companies have continuously enjoyed the numerous benefits of heat exchangers, including the significant cost savings associated with more streamlined electrical cooling. While many of these benefits are obvious, such as the reduced need for energy and more efficient use of physical space, heat exchangers also impact a company’s overhead costs in several other positive ways.

By now, the fact that heat exchangers make electrical thermal management much more efficient is well-known. In most industries, companies have continuously enjoyed the numerous benefits of heat exchangers, including the significant cost savings associated with more streamlined electrical cooling. While many of these benefits are obvious, such as the reduced need for energy and more efficient use of physical space, heat exchangers also impact a company’s overhead costs in several other positive ways.

Cutting down on overall energy needs

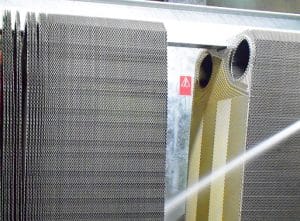

One of the most direct benefits of streamlined thermal management is the reduced need for energy that modern electrical cooling solutions require. For example, heat exchangers such as heat pipes and cold plates work by transferring and dissipating electrical waste heat in a continuous loop. Compared to traditional cooling solutions that chill electrical enclosures using cold air, the more natural heat transfer process can be accomplished using just a fraction of the energy. The more technology a company relies on, the more significant the impact of reducing the energy required to keep their electrical enclosures efficiently cooled.

Reducing maintenance and downtime

In different areas of different industries, technology has been implemented in a wide variety of ways. Many of those are designed to help companies improve their productivity by reducing the amount of maintenance and repairs required to keep things running smoothly. This is especially important when it comes to electrical thermal management. Companies used to rely mostly on solutions like air conditioners and air compressors, which utilize complicated machinery to generate chilled air consistently. Instead of using machinery with many complicated moving parts, heat exchangers use few or no external moving parts. They rely mainly on their cooling fluid and, in some cases, an appropriate number of fans to force more rapid convection.

Boosting overall efficiency and productivity

In addition to the time companies save by reducing the need for maintenance, more natural and efficient cooling solutions like heat exchangers also directly impact the efficiency of the technologies they cool. Transferring waste heat utilizes simpler, more natural processes than traditional HVAC solutions, but the process can be adapted to accommodate some of the most demanding applications in modern industries. This helps ensure that new technologies companies integrate into their workflow perform as well as expected, and with the same level of efficiency that they’re used to enjoying with modern heat exchangers.

For more information about the overall cost savings associated with heat exchangers, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.