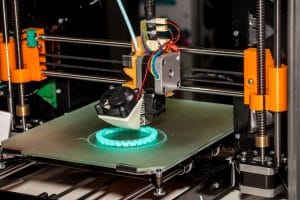

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product.

The common saying to measure twice and cut once is good advice. Yet, with technology, we often take for granted that some things don’t always transfer exactly between an idea or design and the product that is finally produced. At Noren, quality has defined our mission from the beginning. Today, we still measure twice and cut once with the help of 3D printing for in-house prototyping. By rapidly producing prototypes of every component, we can fine-tune designs according to real-world applications before producing the final product.

Save Time from Design to Manufacturing

Effective thermal management grows increasingly more complex as modern technology advances. Operating temperatures, space requirements, accessibility, and more differ from application to application, and thermal management solutions come in a variety of designs to meet these needs. With teams of highly experienced thermal management and engineering experts, Noren has built a reputation of excellence in providing such solutions to clients who operate in virtually every industry.

By combining that expertise with in-house design and manufacturing equipment within the same facility, we’re also able to help clients save time between the design and manufacturing processes for faster and more consistent results. Using 3D printing technology, we go step further in ensuring quality by producing rapid prototypes in-house, allowing for adjustments to be made, if necessary. This eliminates the need to go back to the drawing board because a product doesn’t fit or operate as intended by its design.

A More Competitive Edge with Rapid Prototyping

With the advantage of in-house manufacturing and rapid prototyping, we can give our clients a more competitive edge in thermal management. To learn more, call Noren Thermal, Inc. at 866-936-6736. Now located in Taylor, TX, Noren proudly produces all of our products in the United States and delivers them to clients nationwide.