Noren Thermal has built and maintained a reputation of excellence over the last 40 years when it comes to designing, manufacturing, and improving thermal management solutions. Today, that reputation continues and has expanded thanks to the success of Noren’s wide range of advanced electrical cooling solutions. Much of that success relies on our expertise in heat exchanger design and our in-house manufacturing capabilities, which allow us to conduct comprehensive feasibility studies of every design. A feasibility study can tell you everything you need to know about how your heat exchangers will fit so appropriate adjustments can be made before the final product is created. (more…)

Noren Thermal has built and maintained a reputation of excellence over the last 40 years when it comes to designing, manufacturing, and improving thermal management solutions. Today, that reputation continues and has expanded thanks to the success of Noren’s wide range of advanced electrical cooling solutions. Much of that success relies on our expertise in heat exchanger design and our in-house manufacturing capabilities, which allow us to conduct comprehensive feasibility studies of every design. A feasibility study can tell you everything you need to know about how your heat exchangers will fit so appropriate adjustments can be made before the final product is created. (more…)

Thermal Management Challenges for Medical Devices

Technology has revolutionized how every industry operates, and in many ways, that change is felt most potently in the medical field. From advanced imaging devices to laser diagnostics and surgery, nearly every aspect of health care has been streamlined and improved with the help of technology. To help propel this advancement, Noren’s experts have spent decades innovating and improving thermal management solutions that help medical devices of all kinds, shapes, and sizes operate with optimal efficiency and reliability. (more…)

Technology has revolutionized how every industry operates, and in many ways, that change is felt most potently in the medical field. From advanced imaging devices to laser diagnostics and surgery, nearly every aspect of health care has been streamlined and improved with the help of technology. To help propel this advancement, Noren’s experts have spent decades innovating and improving thermal management solutions that help medical devices of all kinds, shapes, and sizes operate with optimal efficiency and reliability. (more…)

Increased Productivity Starts with Better Thermal Management

Reducing overhead and improving productivity are continuous goals for any company, and finding more efficient thermal management solutions is one of the most overlooked areas to begin. Large equipment, electrical control panels, automated technology, and even certain manufacturing processes all rely on thermal management, often in the form of air conditioning. By relying more on innovative heat exchanger technology, companies can see significant savings in their overall operating costs, as well as units that operate smoother and for much longer than other options. (more…)

Reducing overhead and improving productivity are continuous goals for any company, and finding more efficient thermal management solutions is one of the most overlooked areas to begin. Large equipment, electrical control panels, automated technology, and even certain manufacturing processes all rely on thermal management, often in the form of air conditioning. By relying more on innovative heat exchanger technology, companies can see significant savings in their overall operating costs, as well as units that operate smoother and for much longer than other options. (more…)

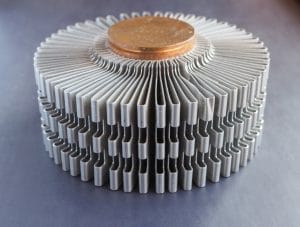

A Brief Look at How Heat Exchangers Work

The good thing about heat exchangers is that they can be crafted and adapted to fit virtually any electrical enclosure. Yet, every system is different, and therefore, heat exchangers must be designed in a variety of different ways to effectively meet each application’s needs. At Noren, our experts specialize in creating thermal management solutions that operate optimally in any given situation. For instance, our air-to-air and air-to-water heat exchangers are certified to operate in a diverse range of conditions, and are manufactured to continue working much longer than more traditional cabinet cooling methods. (more…)

The good thing about heat exchangers is that they can be crafted and adapted to fit virtually any electrical enclosure. Yet, every system is different, and therefore, heat exchangers must be designed in a variety of different ways to effectively meet each application’s needs. At Noren, our experts specialize in creating thermal management solutions that operate optimally in any given situation. For instance, our air-to-air and air-to-water heat exchangers are certified to operate in a diverse range of conditions, and are manufactured to continue working much longer than more traditional cabinet cooling methods. (more…)

Important Reasons to Upgrade to Industrial Heat Exchangers

Manufacturing equipment varies from industry to industry, and even further from organization to organization, in everything from the size and capacity of control panels to the circuits in each piece of machinery. Nevertheless, companies across all industries are increasingly recognizing the importance of upgrading their thermal management systems to more efficient heat exchangers. For over four decades, Noren has continued to provide a wide range of heat exchangers to help clients in every industry reduce the costs and manpower needed to keep their operations running. (more…)

Manufacturing equipment varies from industry to industry, and even further from organization to organization, in everything from the size and capacity of control panels to the circuits in each piece of machinery. Nevertheless, companies across all industries are increasingly recognizing the importance of upgrading their thermal management systems to more efficient heat exchangers. For over four decades, Noren has continued to provide a wide range of heat exchangers to help clients in every industry reduce the costs and manpower needed to keep their operations running. (more…)

Typical Heat Exchanger Applications

The idea of exchanging heat has been around for much of modern man’s history, but utilizing heat transfer concepts to cool electrical equipment is a relatively newer revelation. Since they’ve become an accepted and increasingly more popular option for electrical thermal management, however, heat exchangers have also become an important resource in a number of other manufacturing processes. For virtually all industries, heat exchangers serve a variety of applications, and cooling electrical enclosures is only one of their common uses. (more…)

The idea of exchanging heat has been around for much of modern man’s history, but utilizing heat transfer concepts to cool electrical equipment is a relatively newer revelation. Since they’ve become an accepted and increasingly more popular option for electrical thermal management, however, heat exchangers have also become an important resource in a number of other manufacturing processes. For virtually all industries, heat exchangers serve a variety of applications, and cooling electrical enclosures is only one of their common uses. (more…)

Common Mistakes in Electrical Thermal Management

Designing thermal management for modern electrical enclosures is not always a flawless practice. Many engineers may misjudge the importance of thermal management during a system’s design process, or miscalculate the system’s precise operating temperatures. Even if the design is perfect, the final product may be inhibited by unforeseen circumstances, or by a poor physical fit in the system’s layout. To help our clients avoid common but costly mistakes, we take exceptional care in every step of the process, from design to manufacturing. (more…)

Designing thermal management for modern electrical enclosures is not always a flawless practice. Many engineers may misjudge the importance of thermal management during a system’s design process, or miscalculate the system’s precise operating temperatures. Even if the design is perfect, the final product may be inhibited by unforeseen circumstances, or by a poor physical fit in the system’s layout. To help our clients avoid common but costly mistakes, we take exceptional care in every step of the process, from design to manufacturing. (more…)

Avoiding Condensation While Cooling Control Panels

The main reason for keeping electrical control panels enclosed is to stop environmental influences like dust and condensation from damaging their sensitive components. However, because they’re enclosed, control panels also need to be properly cooled to prevent heat from accumulating too close to those components. In some cases, especially when air conditioning is used to control waste heat, being enclosed may not always be enough to protect electrical components from condensation or the damage that it could cause. With Noren’s heat exchangers and variety of custom thermal management solutions, we can help all of our clients keep their control panels cool while avoiding the potential for condensation. (more…)

The main reason for keeping electrical control panels enclosed is to stop environmental influences like dust and condensation from damaging their sensitive components. However, because they’re enclosed, control panels also need to be properly cooled to prevent heat from accumulating too close to those components. In some cases, especially when air conditioning is used to control waste heat, being enclosed may not always be enough to protect electrical components from condensation or the damage that it could cause. With Noren’s heat exchangers and variety of custom thermal management solutions, we can help all of our clients keep their control panels cool while avoiding the potential for condensation. (more…)

The Evolution of Electrical Thermal Management

Efficiency and productivity have always been a focal point of technology, and as it has advanced throughout the decades, the means for managing electrical waste heat have evolved to keep up. At Noren, innovative thermal management has been our specialty for over 40 years, and we continue to exceed our clients’ expectations by creating solutions to meet every application. As the demand for more efficient and ecofriendly technology has grown, our expertise has helped lead the way in meeting those demands. (more…)

Efficiency and productivity have always been a focal point of technology, and as it has advanced throughout the decades, the means for managing electrical waste heat have evolved to keep up. At Noren, innovative thermal management has been our specialty for over 40 years, and we continue to exceed our clients’ expectations by creating solutions to meet every application. As the demand for more efficient and ecofriendly technology has grown, our expertise has helped lead the way in meeting those demands. (more…)

Choosing Heat Exchangers Based on Comprehensive Analysis

For most electrical systems in most industries and applications, heat exchangers offer a significantly more efficient and reliable solution to thermal management compared to air conditioning. However, with an increasingly wide variety of ecofriendly thermal management solutions, choosing the right heat exchanger should involve a comprehensive analysis of the existing system to determine its exact operating requirements and limitations. At Noren, quality is a defining characteristic of every one of our products, and maintaining our high standards relies largely on the analysis, design, and in-house manufacturing services we provide. (more…)

For most electrical systems in most industries and applications, heat exchangers offer a significantly more efficient and reliable solution to thermal management compared to air conditioning. However, with an increasingly wide variety of ecofriendly thermal management solutions, choosing the right heat exchanger should involve a comprehensive analysis of the existing system to determine its exact operating requirements and limitations. At Noren, quality is a defining characteristic of every one of our products, and maintaining our high standards relies largely on the analysis, design, and in-house manufacturing services we provide. (more…)