For the over four decades that Noren Thermal has been providing innovative thermal management solutions, our focus has always been on helping industries go green. As one of the greatest energy demands for facilities of all kinds, thermal management is one of the most significant areas to begin lowering an organization’s environmental footprint. With that focus in mind, Noren’s advanced heat exchangers are designed according to each client’s unique needs and specifications. We have helped our clients eliminate the need for costly solutions, such as air conditioning equipment, while still effectively and efficiently keeping electrical control panels and enclosures of all kinds adequately cooled. (more…)

For the over four decades that Noren Thermal has been providing innovative thermal management solutions, our focus has always been on helping industries go green. As one of the greatest energy demands for facilities of all kinds, thermal management is one of the most significant areas to begin lowering an organization’s environmental footprint. With that focus in mind, Noren’s advanced heat exchangers are designed according to each client’s unique needs and specifications. We have helped our clients eliminate the need for costly solutions, such as air conditioning equipment, while still effectively and efficiently keeping electrical control panels and enclosures of all kinds adequately cooled. (more…)

Can the Oil & Gas Industry Benefit from Heat Exchangers?

Since they first became an accepted method of electrical thermal management, heat exchangers have been a significant boon to companies in all industries. The innovative electrical cooling units provide a large number of benefits compared to more traditional air conditioning units or compressed air solutions. However, despite their many advantages, heat exchangers do have limitations, and one of those used to be an inability to work in extreme conditions, such as those faced every day by companies in the oil & gas industry. Fortunately, Noren Thermal has closed the gap with its Hazloc line of heat exchangers that are specifically certified for oil and gas, as well as other hazardous industries. (more…)

Since they first became an accepted method of electrical thermal management, heat exchangers have been a significant boon to companies in all industries. The innovative electrical cooling units provide a large number of benefits compared to more traditional air conditioning units or compressed air solutions. However, despite their many advantages, heat exchangers do have limitations, and one of those used to be an inability to work in extreme conditions, such as those faced every day by companies in the oil & gas industry. Fortunately, Noren Thermal has closed the gap with its Hazloc line of heat exchangers that are specifically certified for oil and gas, as well as other hazardous industries. (more…)

Need Better Thermal Management? Consider Heat Exchangers

Throughout history, organizations have automatically considered the high costs of electrical cooling a necessary burden. For instance, control panels and large-scale electrical enclosures only work if a cooling system is present to stop the equipment from overheating. If that means paying exorbitant energy and maintenance costs, then so be it. However, heat exchangers have changed the way organizations view thermal management, making it possible to save costs without sacrificing the ability to prevent electrical overheating. With custom-made heat exchangers from Noren Thermal, companies in all types of industries are able to enjoy better, more reliable, and more cost-effective thermal management solutions. (more…)

Throughout history, organizations have automatically considered the high costs of electrical cooling a necessary burden. For instance, control panels and large-scale electrical enclosures only work if a cooling system is present to stop the equipment from overheating. If that means paying exorbitant energy and maintenance costs, then so be it. However, heat exchangers have changed the way organizations view thermal management, making it possible to save costs without sacrificing the ability to prevent electrical overheating. With custom-made heat exchangers from Noren Thermal, companies in all types of industries are able to enjoy better, more reliable, and more cost-effective thermal management solutions. (more…)

Electrical Control Panel Cooling with Ecofriendly Heat Exchangers

Electrical control panels are utilized for a large variety of applications and systems. Though they vary in size and purpose, all control panels share one vital characteristic—they emit electrical waste heat that must be transferred to avoid electrical overheating. Heat exchangers have long been a go-to option for control panel cooling because they offer highly efficient and greener solutions compared to traditional air conditioners. At Noren, our lineup of innovative thermal management products continues to help all industries enjoy the benefits of energy efficient, ecofriendly heat exchangers. (more…)

Electrical control panels are utilized for a large variety of applications and systems. Though they vary in size and purpose, all control panels share one vital characteristic—they emit electrical waste heat that must be transferred to avoid electrical overheating. Heat exchangers have long been a go-to option for control panel cooling because they offer highly efficient and greener solutions compared to traditional air conditioners. At Noren, our lineup of innovative thermal management products continues to help all industries enjoy the benefits of energy efficient, ecofriendly heat exchangers. (more…)

Efficient, Ruggedized Thermal Management for Military Use

Modern heat exchangers can be found in virtually every industry, and are utilized for an increasingly long list of applications. Noren’s specially certified heat exchangers can even benefit industries that operate in hazardous locations, such as oil and gas refineries or areas where there are large amounts of agricultural dust. Besides protection against harsh environments, however, Noren’s heat exchangers can also be ruggedized to withstand the extreme conditions and treatment that most military equipment goes through. Through ruggedization, we can help ensure that those who serve in our armed forces are equipped with efficient and reliable technology when it matters most. (more…)

Modern heat exchangers can be found in virtually every industry, and are utilized for an increasingly long list of applications. Noren’s specially certified heat exchangers can even benefit industries that operate in hazardous locations, such as oil and gas refineries or areas where there are large amounts of agricultural dust. Besides protection against harsh environments, however, Noren’s heat exchangers can also be ruggedized to withstand the extreme conditions and treatment that most military equipment goes through. Through ruggedization, we can help ensure that those who serve in our armed forces are equipped with efficient and reliable technology when it matters most. (more…)

How to Cool Control Panels in Hazardous Locations

Cooling electrical control panels and other enclosures has become significantly easier since the advent of heat exchangers. In most industries, replacing conventional cooling methods (such as air conditioning and air compression) with greener, more efficient thermal management solutions has led to incredible reductions in both energy consumption and maintenance costs. Heat exchangers also allow for increased productivity while simultaneously lowering a facility’s environmental footprint. Today, one of the greatest advantages of heat exchangers is that they can now be employed even in hazardous locations. Thanks to Noren’s extensive expertise and advanced manufacturing processes, our heat exchangers are certified to provide efficient thermal management under the harshest conditions. (more…)

Cooling electrical control panels and other enclosures has become significantly easier since the advent of heat exchangers. In most industries, replacing conventional cooling methods (such as air conditioning and air compression) with greener, more efficient thermal management solutions has led to incredible reductions in both energy consumption and maintenance costs. Heat exchangers also allow for increased productivity while simultaneously lowering a facility’s environmental footprint. Today, one of the greatest advantages of heat exchangers is that they can now be employed even in hazardous locations. Thanks to Noren’s extensive expertise and advanced manufacturing processes, our heat exchangers are certified to provide efficient thermal management under the harshest conditions. (more…)

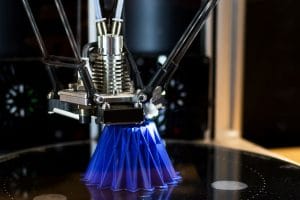

Prototyping Heat Exchanger Designs for Optimal Efficiency

Even the most precise thermal management designs can sometimes underperform once they’ve been integrated into an electrical system. The dimensions of the cooling unit may not fit as snugly as imagined, or it may be situated too closely to sensitive electrical components. Noren not only offers innovative custom-design and in-house manufacturing, but also thorough design analysis and rapid prototyping with 3D printing to avoid thermal management problems that may arise after production. (more…)

Even the most precise thermal management designs can sometimes underperform once they’ve been integrated into an electrical system. The dimensions of the cooling unit may not fit as snugly as imagined, or it may be situated too closely to sensitive electrical components. Noren not only offers innovative custom-design and in-house manufacturing, but also thorough design analysis and rapid prototyping with 3D printing to avoid thermal management problems that may arise after production. (more…)

How Heat Exchangers Boost Agriculture

As the world’s population continues to grow, agricultural industries across the globe have to continue adapting to meet its burgeoning needs. When equipment fails or becomes damaged beyond repair, the failure can have ripple effects throughout the rest of a country’s economy, not to mention the impact on its food supplies. At Noren products, we know that even small details can have monumental consequences, and those consequences are higher in the field of agriculture than they are in many other industries. (more…)

As the world’s population continues to grow, agricultural industries across the globe have to continue adapting to meet its burgeoning needs. When equipment fails or becomes damaged beyond repair, the failure can have ripple effects throughout the rest of a country’s economy, not to mention the impact on its food supplies. At Noren products, we know that even small details can have monumental consequences, and those consequences are higher in the field of agriculture than they are in many other industries. (more…)

Food & Beverage Manufacturing with Heat Exchangers

The methods of growing, cultivating, processing, and packaging food and beverages has advanced greatly over the centuries. From farms to large-scale manufacturers and retailers, technology has streamlined food and beverage production and every industry related to it. A significant factor in this technological advancement has been the development and application of innovative thermal management solutions, such as heat exchangers. By employing heat exchangers, the food & beverage industry has been able to significantly reduce energy costs and improve safety in many food processing procedures, all while helping facilities lower their environmental footprints. (more…)

The methods of growing, cultivating, processing, and packaging food and beverages has advanced greatly over the centuries. From farms to large-scale manufacturers and retailers, technology has streamlined food and beverage production and every industry related to it. A significant factor in this technological advancement has been the development and application of innovative thermal management solutions, such as heat exchangers. By employing heat exchangers, the food & beverage industry has been able to significantly reduce energy costs and improve safety in many food processing procedures, all while helping facilities lower their environmental footprints. (more…)

Science vs. Power: The Advantages of Phase-Change Cooling

Electrical systems generate heat as they operate. Because many electrical circuits are enclosed to protect them from harmful contaminants, that waste heat can easily accumulate into pockets and damage sensitive electrical components. Electrical enclosures must remain cool to operate properly, and conventional methods such as air conditioning, which require excessive amounts of power, are not always financially or operationally viable. By contrast, modern heat exchangers utilize scientific processes, such as phase-change cooling, to provide consistent thermal management without drawing on large amounts of energy. (more…)

Electrical systems generate heat as they operate. Because many electrical circuits are enclosed to protect them from harmful contaminants, that waste heat can easily accumulate into pockets and damage sensitive electrical components. Electrical enclosures must remain cool to operate properly, and conventional methods such as air conditioning, which require excessive amounts of power, are not always financially or operationally viable. By contrast, modern heat exchangers utilize scientific processes, such as phase-change cooling, to provide consistent thermal management without drawing on large amounts of energy. (more…)