There are many different electrical cooling processes that have benefited from the efficiency and reliability of modern heat exchangers. From cooling electrical enclosures and control panels to creating opportunities for greener practices on a wider scale, heat exchangers have provided optimal thermal management to a wide range of applications. More recently, those applications include vital processes such as wastewater treatment, which is required for companies in several different types of industries. The custom thermal solutions made possible with heat exchangers have also made the process of applying heat to treat wastewater much more streamlined and eco-friendlier. (more…)

There are many different electrical cooling processes that have benefited from the efficiency and reliability of modern heat exchangers. From cooling electrical enclosures and control panels to creating opportunities for greener practices on a wider scale, heat exchangers have provided optimal thermal management to a wide range of applications. More recently, those applications include vital processes such as wastewater treatment, which is required for companies in several different types of industries. The custom thermal solutions made possible with heat exchangers have also made the process of applying heat to treat wastewater much more streamlined and eco-friendlier. (more…)

Optimized Electrical Cooling in Hazardous Locations

The secret to how heat exchangers made such an impact on electrical thermal management lies in their simplicity. Rather than generating chilled air and circulating it through electrical enclosures, the more advanced enclosure cooling units simplify the process by simply collecting and transferring electrical waste heat within a continuous loop. While this dramatically improved thermal management costs and operations within manufacturing and other facilities, it didn’t quite solve the problem for industries that operate in more hazardous locations and conditions. Now, however, such industries have several hazardous location heat exchanger designs to choose from, allowing them to experience the same advanced thermal management benefits as other industries. (more…)

The secret to how heat exchangers made such an impact on electrical thermal management lies in their simplicity. Rather than generating chilled air and circulating it through electrical enclosures, the more advanced enclosure cooling units simplify the process by simply collecting and transferring electrical waste heat within a continuous loop. While this dramatically improved thermal management costs and operations within manufacturing and other facilities, it didn’t quite solve the problem for industries that operate in more hazardous locations and conditions. Now, however, such industries have several hazardous location heat exchanger designs to choose from, allowing them to experience the same advanced thermal management benefits as other industries. (more…)

An Eco-Friendly Way to Achieve Below-Ambient Cooling

Heat exchangers have always been widely recognized as the more eco-friendly cooling solution for most electrical systems. Compared to more traditional solutions, the unique heat transfer concepts that heat exchangers use to prevent electrical overheating are much less energy and cost intensive, and they don’t allow for the release of any contaminants into the environment. However, within conventional heat exchangers, those same concepts only achieve ambient cooling, or cooling the inside of an electrical enclosure to just above the ambient temperature outside of it. While this is more than adequate for most common applications with high maximum operating temperatures, there are many different applications that require below-ambient cooling for several different reasons. (more…)

Heat exchangers have always been widely recognized as the more eco-friendly cooling solution for most electrical systems. Compared to more traditional solutions, the unique heat transfer concepts that heat exchangers use to prevent electrical overheating are much less energy and cost intensive, and they don’t allow for the release of any contaminants into the environment. However, within conventional heat exchangers, those same concepts only achieve ambient cooling, or cooling the inside of an electrical enclosure to just above the ambient temperature outside of it. While this is more than adequate for most common applications with high maximum operating temperatures, there are many different applications that require below-ambient cooling for several different reasons. (more…)

Can Companies Really Produce More with Heat Exchangers?

After upgrading their electrical thermal management systems to heat exchangers, companies almost immediately experience a wide variety of benefits. From lower energy costs to a more streamlined and esthetic footprint, to the optimization of a company’s employees and technologies, the benefits of advanced electrical cooling often speak for themselves. However, the overall advantage of improved efficiency and productivity continue to grow more pronounced the longer companies rely on heat exchangers, and the more applications they utilize them for. In virtually every industry, the implementation of heat exchangers has become an essential part of streamlining overall production. (more…)

After upgrading their electrical thermal management systems to heat exchangers, companies almost immediately experience a wide variety of benefits. From lower energy costs to a more streamlined and esthetic footprint, to the optimization of a company’s employees and technologies, the benefits of advanced electrical cooling often speak for themselves. However, the overall advantage of improved efficiency and productivity continue to grow more pronounced the longer companies rely on heat exchangers, and the more applications they utilize them for. In virtually every industry, the implementation of heat exchangers has become an essential part of streamlining overall production. (more…)

What Heat Exchangers Can Do Besides Electrical Cooling

When it comes to modern electrical cooling and thermal management solutions, heat exchangers are often the optimal solution for a wide range of applications. For instance, they’ve long been recognized as a more affordable, efficient, and reliable alternative to cumbersome solutions such as air conditioners. More recently, their eco-friendly and nearly automated functions have made heat exchangers the preferred electrical cooling solution for increasingly more advanced applications. However, they’ve also become popular solutions for applications beyond cooling electrical control panels and other enclosures. With their ability to successfully absorb and transfer large amounts of heat without allowing for any notable rises in temperature, and without requiring exorbitant amounts of energy, heat exchangers have become ideal solutions for thermal management applications of all types. (more…)

When it comes to modern electrical cooling and thermal management solutions, heat exchangers are often the optimal solution for a wide range of applications. For instance, they’ve long been recognized as a more affordable, efficient, and reliable alternative to cumbersome solutions such as air conditioners. More recently, their eco-friendly and nearly automated functions have made heat exchangers the preferred electrical cooling solution for increasingly more advanced applications. However, they’ve also become popular solutions for applications beyond cooling electrical control panels and other enclosures. With their ability to successfully absorb and transfer large amounts of heat without allowing for any notable rises in temperature, and without requiring exorbitant amounts of energy, heat exchangers have become ideal solutions for thermal management applications of all types. (more…)

What’s So Eco-Friendly About Heat Exchangers?

Eco-friendliness wasn’t always a significant, wide-spread concern among most industries. However, saving money always has been, and when it comes to streamlining thermal management costs, heat exchangers have consistently been the preferred solution for decades. Now that minimizing environmental impacts and implementing greener, more eco-friendly solutions have become industry standards, heat exchangers continue to excel thanks to their more energy and cost-efficient thermal management processes. (more…)

Eco-friendliness wasn’t always a significant, wide-spread concern among most industries. However, saving money always has been, and when it comes to streamlining thermal management costs, heat exchangers have consistently been the preferred solution for decades. Now that minimizing environmental impacts and implementing greener, more eco-friendly solutions have become industry standards, heat exchangers continue to excel thanks to their more energy and cost-efficient thermal management processes. (more…)

How Thermal Management Benefits from Heat Exchangers

Whether it’s the significantly reduced costs or the lower energy requirements compared to other cooling solutions, heat exchangers have provided a wide range of extensive benefits to the realm of thermal management. For example, the process of cooling electrical enclosures and control panels in large manufacturing operations is made much simpler when companies don’t have to rely on difficult-to-manage air conditioning or air compressing equipment. The secret to those benefits lies largely in the innovative approaches that heat exchangers take to handing electrical waste heat. By using natural, eco-friendly heat transfer processes instead of more demanding HVAC technologies, heat exchangers have streamlined electrical thermal management in several important ways. (more…)

Whether it’s the significantly reduced costs or the lower energy requirements compared to other cooling solutions, heat exchangers have provided a wide range of extensive benefits to the realm of thermal management. For example, the process of cooling electrical enclosures and control panels in large manufacturing operations is made much simpler when companies don’t have to rely on difficult-to-manage air conditioning or air compressing equipment. The secret to those benefits lies largely in the innovative approaches that heat exchangers take to handing electrical waste heat. By using natural, eco-friendly heat transfer processes instead of more demanding HVAC technologies, heat exchangers have streamlined electrical thermal management in several important ways. (more…)

Heat Exchangers Used as Rugged Thermal Solutions

The pace at which heat exchangers have evolved to keep up with advancing technologies has proven the versatility that they bring to modern electrical cooling and thermal management. From electrical enclosure cooling to providing thermal solutions for innovative and eco-friendly processes, heat exchangers have transformed the way today’s technologies approach thermal management. However, the advancement of heat exchangers into certain fields of operations, such as military, aerospace, oil and gas, and other hazardous fields, has been slightly slower. That’s because such applications not only require high-performance, eco-friendly thermal management, but cooling solutions must also be rugged enough to adequately withstand some of the most demanding conditions. (more…)

The pace at which heat exchangers have evolved to keep up with advancing technologies has proven the versatility that they bring to modern electrical cooling and thermal management. From electrical enclosure cooling to providing thermal solutions for innovative and eco-friendly processes, heat exchangers have transformed the way today’s technologies approach thermal management. However, the advancement of heat exchangers into certain fields of operations, such as military, aerospace, oil and gas, and other hazardous fields, has been slightly slower. That’s because such applications not only require high-performance, eco-friendly thermal management, but cooling solutions must also be rugged enough to adequately withstand some of the most demanding conditions. (more…)

Cold Plates for Custom, Eco-Friendly Thermal Management

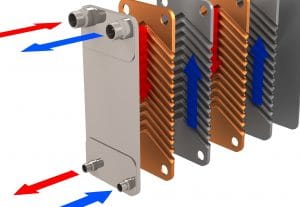

Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods. (more…)

Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods. (more…)

Using Heat Exchangers for More than Cooling Enclosures

For the application of cooling electrical enclosures, such as control panels, heat exchangers have excelled for decades. It isn’t just their reliability in consistently cooling such enclosures, but also the ability to do so with minimal energy, maintenance, and repair requirements. Given the many important benefits that they provide in electrical cooling, it’s only natural that the same efficient and eco-friendly heat transfer principles have led to thermal management innovations in areas beyond just keeping electrical enclosures cooled. Today, heat exchangers are commonly used for an increasingly wider variety of applications, which adds to their growing popularity across virtually every industry. (more…)

For the application of cooling electrical enclosures, such as control panels, heat exchangers have excelled for decades. It isn’t just their reliability in consistently cooling such enclosures, but also the ability to do so with minimal energy, maintenance, and repair requirements. Given the many important benefits that they provide in electrical cooling, it’s only natural that the same efficient and eco-friendly heat transfer principles have led to thermal management innovations in areas beyond just keeping electrical enclosures cooled. Today, heat exchangers are commonly used for an increasingly wider variety of applications, which adds to their growing popularity across virtually every industry. (more…)