If you work in injection molded plastic production, then you know how important it is to keep a close eye on the temperatures in and around your molds. Things can go wrong in an instant in this industry, and when that happens, it can mean leaving you with a bunch of useless waste instead of sellable products. Heat is one of the most critical risks to handle in plastic manufacturing, and if you are still relying on traditional thermal management for your protection, it is time to think about making a change.

If you work in injection molded plastic production, then you know how important it is to keep a close eye on the temperatures in and around your molds. Things can go wrong in an instant in this industry, and when that happens, it can mean leaving you with a bunch of useless waste instead of sellable products. Heat is one of the most critical risks to handle in plastic manufacturing, and if you are still relying on traditional thermal management for your protection, it is time to think about making a change.

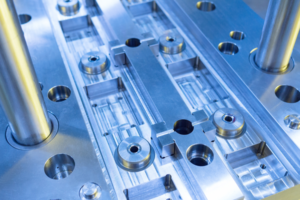

With our team of thermal energy experts at Noren Thermal Solutions in Taylor, TX, you can take steps to improve your efficiency in plastic production. For over 55 years, we have been designing and creating quality cooling systems for a range of industries, and we have seen a thing or two in our time. From specially crafted air-to-air and air-to-water heat exchangers to custom heat pipe assemblies and thermal pins tailored for injection molded plastic production, our team has you covered. To find out more about efficient injection molding thermal management, speak with one of our representatives today!

Injection Molded Plastic Production Requires Dedication To Your Temperatures

Are you still depending on traditional thermal management for your injection molded plastic production operation? If so, you could be wasting money on energy, while seeing unreliable or inconsistent results. Air conditioning may work great for your house or car, but when it comes to industrial applications, it just might be too inefficient for your workspace.

In the injection molding industry, you do not have time for continued mistakes. Talk to our team about the advantages of effective thermal management for your business. We offer a range of products designed to help companies just like yours to achieve more optimal working conditions and maintain them with consistency.

You Have Options In Efficient Injection Molding Thermal Management

At our shop in Taylor, Texas, we design and create a range of thermal management products, and we understand the challenges that can come with plastic manufacturing. When you need to upgrade or replace your existing mold cooling system, talk to us about ways to enhance your approach. With our custom heat pipe assemblies, you can reach areas where other methods simply cannot, and thermal pins are a dedicated device, designed for even and effective cooling across your molds. This can often reduce cycle time and improve product quality, so ask about your options.

Enhance Your Mold Cooling With Noren Thermal Solutions

To learn more about the advantages of thermal pins for injection molding, speak with one of our representatives at Noren Thermal Solutions in Taylor, TX at 512-595-5700 today!