Do you operate a business with significant excess heat production? Protecting your sensitive equipment from the thermal waste it produces can be a challenge. While a traditional air conditioning system can help you reduce overall temperatures, these systems can require high energy. Failing to anticipate your thermal management needs can lead to overheating situations that permanently damage your application or threaten the well-being of your employees. In the twenty-first century, all companies operate local servers that process tasks throughout the business day. This means that a lag in production from overheating can bring your entire company to a standstill. By taking advantage of a more passive form of thermal management, you can prevent these negative outcomes without breaking the bank. By placing a set of cold plates near the equipment generating thermal waste, we can send a tube full of cooling to absorb excess energy. We can even combine this heat exchanger with other methods to increase the efficiency of your production.

At Noren Thermal Solutions, we understand how important protecting your electronics and other heat-sensitive equipment is to your company. We have been in business for over 50 years, helping companies like yours implement thermal management techniques that allow them to operate without delay. We can examine your current setup or help design one entirely from the ground up. Our range of thermal management products helps us make your vision a reality.

Liquid Contact Cooling Brings Your Temperatures Into Range

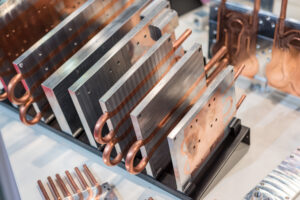

The design of a custom cold plate relies upon base metals that utilize attractive conductive capabilities. By selecting aluminum or copper, we take advantage of the ability to transfer large amounts of excess heat waste per square inch of contact. By using these ambient heat exchangers, we send a tube of cooling through the metal to transfer excess heat waste away to a safer location.

When you meet with the team at Noren, we will analyze your current needs to help determine which products best protect your machinery. You may be surprised at how easily one of our custom cold plates can interact with your pre-existing applications.

A Versatile Form Of Heat Exchange

We may suggest combining your cold plate with other equipment such as our heat sinks to maximize their effectiveness. Used in a chain, a cold plate can directly absorb temperatures while heat sinks placed near electronics take advantage of ambient exchange. This method absorbs temperatures through the surrounding air using a system of fins that expand surface area.

Speak With The Experts From Noren About Taking Advantage Of A Cold Plate Solution

Products such as heat sinks and cold plates help you transfer heat waste without amplifying energy costs. To learn more about how we help you manage waste heat, speak with a valued team member at Noren Thermal Solutions at (512)595-5700.