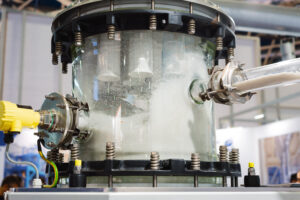

If you work in the production of manufactured plastic goods, you know how stressful the process can be. The most common form of this form of creation is through a process known as injection molding. This industrial application can be especially tricky for business owners. Multiple thermal management scenarios exist within this process, from the computerized products to automated systems. The injection molding itself can require a sophisticated solution to redirect high temperatures away from your vital equipment.

If you work in the production of manufactured plastic goods, you know how stressful the process can be. The most common form of this form of creation is through a process known as injection molding. This industrial application can be especially tricky for business owners. Multiple thermal management scenarios exist within this process, from the computerized products to automated systems. The injection molding itself can require a sophisticated solution to redirect high temperatures away from your vital equipment.

Traditional forms of air conditioning can be inefficient at best. These systems are wasteful both to the environment and your finances. Instead, rely upon the laws of thermodynamics with a system from Noren Thermal Solutions in Taylor, TX. Our thermal pins conduct heat more efficiently to reroute your thermal energy into a location that is safe for your equipment and your employees. Operate effectively and consistently to maximize revenue through being able to deliver a solid manufactured plastic product to your vendors on time. You have the power to grow your business with a better production line and solid output!

Meeting Your Thermal Management Needs For Injection Molding

Plastic manufacturing through the molding process is highly temperature-specific. Each step along the way requires the proper level of heat so that the materials harden accurately. Even the smallest of changes to this can leave you with a subpar product that you do not feel comfortable giving to your vendors. Deliver your plastic with pride when you appropriately care for your thermodynamic needs.

Discover The Difference With More Efficiency

Thermal pins help by transferring energy from your vulnerable electronics and manufacturing machinery. These take heat and draw them to another area, often a water source. Speak with our team about the forms of thermal pins. They can help you find the best solution for your business.

Certain forms of injection molding require small core solutions. Thermal pins help to move heat from tighter locations that other methods cannot reach. Discover the benefits of thermal pins in helping your business maintain efficiency.

Helping Your Business Through Stability With Noren Thermal Solutions

Injection molding requires sophisticated thermal management systems. Improper cooling can lead to waste of product or the creation of subpar goods. Deliver a quality product on time with efficient thermal pins to help your plastic manufacturing process. Limit the loss of financial resources from the loss of product, as well.

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative from our team to learn more about how our thermal pins can help you to avoid costly delays in production. Keep your quality up as well and limit the resource waste of a poor system.