For over fifty years, our team has utilized collaborative engineering and our years of expertise to help you find the ideal thermal solution that is needed for your specific needs. Indeed, thermal management is an essential process that helps prevent overheating in industrial applications, but what exactly does this mean, and how exactly does it all work? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the many components we use to promote optimal thermal management and explains how each method could benefit specific industries and businesses.

For over fifty years, our team has utilized collaborative engineering and our years of expertise to help you find the ideal thermal solution that is needed for your specific needs. Indeed, thermal management is an essential process that helps prevent overheating in industrial applications, but what exactly does this mean, and how exactly does it all work? In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the many components we use to promote optimal thermal management and explains how each method could benefit specific industries and businesses.

Causing Heat to Spread

For the purposes of this blog, thermal management can be described as any practice that aims to reduce the presence of waste heat within a technological enclosure in order to promote sustainable function and optimal usage. Indeed, not all applications are created with heat regulation in mind, but most all of them require some sort of heat exchanger to get the job done. This is where our team comes in to help.

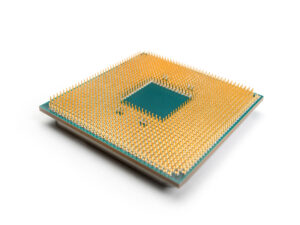

You see, a major part of what makes our heat exchangers so desirable is that they begin with simple yet sustainable components. Take, for example, the heat spreader. A heat spreader is a device used to move heat from a concentrated source to an exchanger with a large surface area or volume. The idea is that, when allowed to occupy more space, the waste heat will reduce.

When looking at these concepts in action, it becomes clear that a heat spreader acts as a primary heat exchanger between the source and a secondary thermal solution. The rate at which energy is transferred depends largely on the material the spreader is made from, and our team will work with you to determine your ideal options. To learn more about this process and how we can help, give us a call today.

Understanding Resistance and Conductance

In addition to heat spreading, other solution components to note include thermal resistance and thermal conductance. These components are used within heat sink thermal solutions. Thermal resistance is measured as a result from junction to the case of the semiconductor device, whereas conductance measures the quality of heat that passes through a plate of a particular area and thickness. Together, these components make up the method behind heat sink thermal management. Contact our team to learn more.

Evaporators, Condensers, and Heat Pipe Performance

Last, but most certainly not least, we have evaporators and condensers which contribute to heat pipe performance. You see, the evaporator is the heat input area while condensers measure the heat output area. Together, these components make up the phase-chance method of thermal transfer our heat pipe solutions use.

Get Started Today

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to learn more about the many components that make up the thermal management process within a given application, and speak to a representative from our team to get started on yours today.