Staying on top of your thermal management capabilities requires gaining a detailed-enough understanding of the parameters and circumstances that influence its function. In other words, simply purchasing a small fan to cool an overheating application will not be nearly as effective as implementing a customized heat exchanger solution, and the more you know about your parameters the better off you will be. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the varying components of our new Eco-Cool Heat Exchanger, as well as what you can expect in various conditions.

Staying on top of your thermal management capabilities requires gaining a detailed-enough understanding of the parameters and circumstances that influence its function. In other words, simply purchasing a small fan to cool an overheating application will not be nearly as effective as implementing a customized heat exchanger solution, and the more you know about your parameters the better off you will be. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the varying components of our new Eco-Cool Heat Exchanger, as well as what you can expect in various conditions.

Utilizing a Heat Sink Profile

By now, you are likely familiar with the notion of overheating electronics. After all, you would not expect a person to continue consistent activity without becoming fatigued, so what makes you think an application wouldn’t experience a similar concern? Indeed, overheating is what happens when the internal temperature of a technological application rises to above safe operating temperatures. What’s more? This can lead to temporary breakdown, electrical fires, and even permanent damage.

In order to ensure your equipment is functioning properly in your environment, it is highly recommended that you pursue a custom heat exchanger thermal solution. Products such as our Eco-Cool Heat Exchangers offer the most in application cooling by employing high-quality methods at low cost to you. But how exactly do they work?

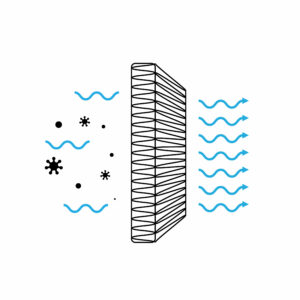

By utilizing heat sink technology, hot air inside of the enclosure circulates throughout internal fins via specialized fans. In doing so, the cooler ambient air is brought into the enclosure while pushing the warmer internal air out. To learn more about this process and how our team can help you get started, give us a call.

Built to Standard Specifications

In addition to an efficient and effective thermal management profile, our Eco-Cool models can be designed to adhere to various industry-wide standards. For instance, we manufacture heat exchangers that are consistent with NEMA 12, 4, and 4X enclosure types.

Another major component of our designs is the ability to accommodate different application model types, including drop-in and flush-mount attachments. In other words, we take your parameters carefully into consideration in order to help provide the best solution for optimal capabilities. Give our team a call today to learn how you can get started.

Minimal Power Consumption

Use of power and cost of operation is often a major deterrent for many, but we believe this should not be a barrier to ideal function. Not only does the Eco-Cool heat Exchanger highly efficient, but it is eco-friendly and offers low electrical consumption.

Speak with Our Team

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to learn how a custom thermal solution can enhance your operational capabilities, and speak with a representative from our team to get started today.