Nothing is more frustrating than attempting to optimize your capabilities through the use of a heat exchanger, just for your industrial application to breakdown shortly thereafter. Indeed, this is an unavoidable fate if you continue to fall victim to the appeal of one-size-fits-all solutions, as nothing can benefit your applications more than customized products. While you may be hesitant to pursue a custom solution for financial or efficiency reasons, feasibility studies and product testing helps ensure you receive nothing short of ideal. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a deeper look into the benefits of early product testing when seeking thermal solutions.

Nothing is more frustrating than attempting to optimize your capabilities through the use of a heat exchanger, just for your industrial application to breakdown shortly thereafter. Indeed, this is an unavoidable fate if you continue to fall victim to the appeal of one-size-fits-all solutions, as nothing can benefit your applications more than customized products. While you may be hesitant to pursue a custom solution for financial or efficiency reasons, feasibility studies and product testing helps ensure you receive nothing short of ideal. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a deeper look into the benefits of early product testing when seeking thermal solutions.

How to Begin the Process

As technological advancement has continued to influence the world as we know it, we are seeing a steadily growing world population in addition to ever-increasing rises in product demand. Indeed, various industries exist to help us farm resources from the planet, create products needed for everyday function, and a host of other purposes. As such, these fields must utilize their resources accordingly to meet this demand.

In order to get the most out of your technological applications, however, it is important to recognize the role your physical environment and parameters have on functional capabilities. For example, heightened operating temperatures within an application can easily leads to overheating, temporary break down, or even permanent damage.

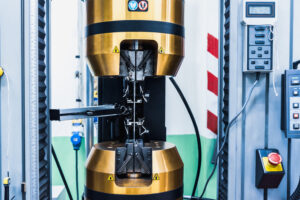

This is where a custom thermal solution comes into play. You see, our team will work with you to identify your contributing parameters and needs so that you can optimize your application’s capabilities. In order to meet this need, however, our team will conduct feasibility studies, protypes, and of course, product test. For more information about this process, give our team a call today.

Why We Prototype and Test

We recognize that among various fields, industry-wide standards must be kept and maintained to ensure proper performance and safety. Additionally, it is important to consider the consequences of faulty heat exchangers or one-size-fits-all approaches, which is why we aim for custom products from the get-go. As with all of our products, we offer customized testing procedures to meet your requirements. Further, early prototyping and testing allows for decrease in costs overall, as modifications can be completed in-house before scheduling your installation. To learn more, reach out to a representative from our team.

Providing High-Quality Solutions

For over fifty years, our team of collaborative engineers, manufacturers, and designers have placed an equal emphasis on results and sustainability. You do not have to worry about sacrificing quality for environment, and we will work closely with you to ensure your needs are met.

Learn More Today

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative from our team and learn how you can get started on your custom thermal solution today.