Whether you work at a Coca-Cola plant, in the Oil & Gas field, or with wastewater treatment, your equipment is an essential part of making the process happen. Indeed, a variety of heat exchangers and other thermal accessories exist to streamline production and increase yields, and the number one way to ensure the line is up and running is with effective application cooling. Further, it is best to address your needs precisely rather than with a one-size-fits-all approach. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores specifications for NEMA 4X enclosure types, as well as how our products meet these regulations.

Whether you work at a Coca-Cola plant, in the Oil & Gas field, or with wastewater treatment, your equipment is an essential part of making the process happen. Indeed, a variety of heat exchangers and other thermal accessories exist to streamline production and increase yields, and the number one way to ensure the line is up and running is with effective application cooling. Further, it is best to address your needs precisely rather than with a one-size-fits-all approach. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores specifications for NEMA 4X enclosure types, as well as how our products meet these regulations.

Which Industries Utilize 4X

The National Electrical Manufacturers Association (NEMA) sets standards for a variety of Industrial-grade applications and electrical equipment. This is to ensure a consistent level of quality across a wide variety of thermal management solutions and products.

Not only does NEMA set these standards to ensure baseline quality, but a list of standards is defined to address the needs of multiple enclosure types. For example, you would not expect a Food & Beverage application to contain the same exact parameters as an Oil & Gas application, so why would you rely on a product that touts the ability to address the needs of both?

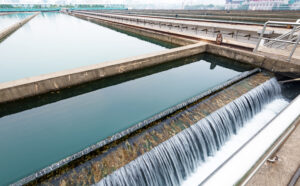

When taking a look at NEMA 4X enclosure cooling, we can see that these types of enclosures are often intended for applications used in dairies, ship docks, and wastewater treatment. As such, you can deduce that a standard component of these types of enclosures has to do with preventing water from entering the panel. To learn more about this process, give our team a call today.

Standard Components

It goes without saying that one of the more difficult environments to cool overheating applications in is wastewater treatment. Indeed, if water infiltrates an electrical enclosure, you can expect to experience a number of complications. For example, breakdown and permanent damage are likely, and replacing these electronics will cost you significantly in terms of time and profit.

As such, it is important that custom thermal solutions that are intended for wastewater treatment follow a few standard guidelines. This includes the ability to make a watertight connection and exclude no less than 65 gallons per minute of water or fluid. Contact our team to learn more about this process today.

Optimizing Your Processes

Our team recognizes the importance of consistency and dependability. Further, we work closely with you and your team to ensure your parameters are considered and your needs are met as ideally as possible.

Learn More Today

Don’t settle for subpar thermal solutions, and get the most from your applications. Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 and speak to a representative from our team today.