Consistent use of motors and other components within your industrial applications will inevitably lead to overheating, especially if you have not made accommodations to prevent it. Indeed, this is often the biggest oversight of many industrial application production companies and one that must certainly be addressed in order to optimize your business’ function. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the benefits of liquid cold plate cooling, and how it can lead to higher efficiency for production.

Consistent use of motors and other components within your industrial applications will inevitably lead to overheating, especially if you have not made accommodations to prevent it. Indeed, this is often the biggest oversight of many industrial application production companies and one that must certainly be addressed in order to optimize your business’ function. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX explores the benefits of liquid cold plate cooling, and how it can lead to higher efficiency for production.

Heat Transfer Over Large Areas

When a person goes for a run in the hot sun, you would not expect that person to be able to sprint an entire mile with no breaks or means for staying cool, right? Though humans and technology vary in more ways than one, this is one area in which they are both pretty similar. Indeed, the majority of industries rely heavily on advanced technology to accomplish their tasks, and having the line cease production due to a technological malfunction can cost a company significantly.

Since motors and other components within a technological device produce waste heat as they function, overheating is one of the top concerns a company should worry about. After all, if there is no way to expel this waste, then you can expect internal temperatures to rise to dangerous levels. Fortunately, that is where thermal management capabilities come in to help.

Thermal management concepts operate with the primary goal of removing waste heat. This can be accomplished through spreading, movement, or dissipation. What’s more? Our team places an emphasis on optimal use as well, meaning we can customize our products to fit your needs closely, thus helping you get the most out of your applications. Reach out to our team today to learn more about this process.

Necessary Internal Cooling

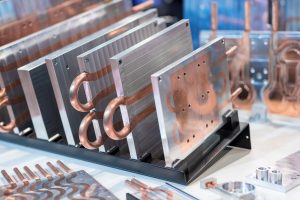

When it comes to sensitive electronics and functioning motors, one of our more popular solutions includes our liquid cold plate heat exchangers. These devices consist of large, flat metal plates that contain tubing to help dispel waste heat across its area, subsequently resulting in the cooling of that device.

Our cold plate solutions utilize liquid to help cool your electronics rapidly. Indeed, these devices can fit into tight spaces, and we custom design the flow paths that are connected to them in order to achieve the highly specific cooling parameters of a given application.

A Wider Variety of Applications

Because of the use of effective phase-change cooling, our custom cold plates help to bring the high-performance, low-cost capabilities of traditional liquid cooling to an even wider variety of both common and non-typical applications.

Speak with Our Team

To learn more about the benefits of cold plate cooling or to speak to a representative from our team, contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 today.