There are many factors to take into consideration when attempting to streamline your thermal management capabilities. Indeed, the cost is one of the most important, as are function, space allotted, environmental factors and influences, and so much more. In some ways, for example, competing companies tout the ability to offer efficiency in preventing overheating in industrial applications while increasing productivity and yields through complex methods. Our team, however, innovates to provide quality solutions that utilize simpler concepts. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the role our thermal pin heat exchangers play in not only preventing your equipment from overheating but increasing yield and cycle times as well.

There are many factors to take into consideration when attempting to streamline your thermal management capabilities. Indeed, the cost is one of the most important, as are function, space allotted, environmental factors and influences, and so much more. In some ways, for example, competing companies tout the ability to offer efficiency in preventing overheating in industrial applications while increasing productivity and yields through complex methods. Our team, however, innovates to provide quality solutions that utilize simpler concepts. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will discuss the role our thermal pin heat exchangers play in not only preventing your equipment from overheating but increasing yield and cycle times as well.

Rapid Heating and Cooling

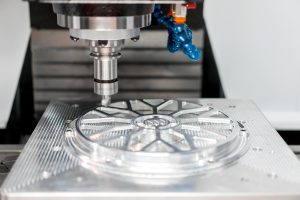

In industries that utilize plastic mold cooling such as Food & Beverage, among others, the ability to rapidly heat and subsequently cool the material is essential. Indeed, material processing has benefitted significantly from technological innovation, including higher-quality heat exchangers. For the molding industry in particular, these benefits are exceptional.

Because most businesses that operate on molding capabilities rely heavily on their cycle times and quality of products, a consistent thermal management solution is a must. After all, much of the profit and success comes from high-quality outputs that can be generated in a quick and timely fashion.

The secret behind creating such quality plastics lies behind the heating and cooling process. For instance, the plastic material must be heated rapidly to the point that it melts so that it can fill the mold properly, but then be subsequently cooled so that it can take on the shape of the mold and become solid again without discrepancies. For more information about this process, reach out to our team today.

Even Distribution

While rapid heating can be achieved through increased temperatures, bear in mind that there is a threshold at which the material becomes too hot to settle correctly. What’s more? An uneven mold thickness coupled with extreme temperatures can lead to quality concerns such as pulling, spotting, or sink marks. Fortunately, this is where our team comes in to help.

Our custom thermal pin heat exchangers consist of a small hollow core that allows for a more even distribution across the material as well as higher quality output. Reach out to a representative from our team to learn more.

Addressing a Variety of Needs

We recognize that not all technologies are created the same, nor do they have the same needs. Because of this, we customize every thermal pin to fit most molding apparatuses. These include extrusion, injection, rotational, and blow molding.

Learn More Today

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 today and ask our team about your thermal management options, or get started on your custom product.