When it comes to technological applications, one thing will always remain true: thermal management capabilities are needed in order to truly help you get the most from your machines. The problem is, however, that not all applications are created the same, and sometimes it can be difficult to discern which methods are best for your particular business or industry. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a dive into the inner workings of effective heat exchangers, and details how you can achieve rapid thermal dissipation with our Copper-Finned Heat Sinks.

When it comes to technological applications, one thing will always remain true: thermal management capabilities are needed in order to truly help you get the most from your machines. The problem is, however, that not all applications are created the same, and sometimes it can be difficult to discern which methods are best for your particular business or industry. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a dive into the inner workings of effective heat exchangers, and details how you can achieve rapid thermal dissipation with our Copper-Finned Heat Sinks.

Understanding the Basics

To determine the ideal solution for your equipment, an understanding of your thermal budget is needed. This means being aware of the amount of energy you can provide for an application to effectively perform its role. To do this, we utilize three main strategies that are intended to add efficiency to the process.

The thermal management concepts our team utilizes to effectively remove waste heat involve spreading, movement, and dissipation. Indeed, some of our products utilize a combination of these methods, while some focus primarily on one method or another.

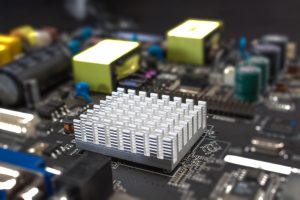

To begin explaining the heat dissipation process, we will take a look at our custom heat sinks as an example. This product is constructed from a solid, flat base with a number of perpendicular fins jutting out from it. As a technological application’s internal temperature begins to rise, the base of the sink absorbs this waste and pushes it through the many fins and into the surrounding air, effectively dissipating the energy. For more information about this process, reach out to our team today.

Benefits of Copper

Another important consideration when attempting to optimize your thermal management capabilities involves what materials and resources are used. For instance, our heat sink heat exchangers are made from copper, as copper has an extremely high and effective rate of thermal transfer.

With roughly two to three times the transfer rate of traditional aluminum sinks, our Copper-Finned products allow your applications to displace waste energy at a much faster rate. What’s more? You can benefit from increased yields, production, and more with reliable and consistent applications with quality management capabilities. For more information about effective transfer, speak to a representative from our team today.

Optimizing Your Applications

It is one thing to prevent your technologies from breaking down or overheating, but it is completely different to do so and optimize your output. Indeed, we have moved past a one-size-fits-all approach, embracing the major benefits of customization and quality design, and our team is ready to help yours today.

Learn More Today

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a member of our team and get started on your custom solution today.