When it comes to application cooling and prevention of overheating, the most important factor to keep in mind involves knowing how waste heat can be removed from a source. To accomplish this, concepts such as movement, spread, and dissipation are considered. Indeed, some methods are more effective for certain industries or companies with unique environments, and not all applications are created equally. This means customization also plays a major role. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at the concept of waste spread and dissipation, and how our Copper Finned Heat Sinks accomplish this goal.

When it comes to application cooling and prevention of overheating, the most important factor to keep in mind involves knowing how waste heat can be removed from a source. To accomplish this, concepts such as movement, spread, and dissipation are considered. Indeed, some methods are more effective for certain industries or companies with unique environments, and not all applications are created equally. This means customization also plays a major role. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX will take a look at the concept of waste spread and dissipation, and how our Copper Finned Heat Sinks accomplish this goal.

Protecting Sensitive Electronics

As the world continues through this technologically-driven information age, the thought of optimizing yield or output is largely improbable without the use of technology. Indeed, new ideas and inventions have been able to not only streamline a number of processes but optimize their use as well.

What should be kept in mind, however, is that any tool has a breaking point. In other words, waste heat is generated as equipment performs as needed, and without proper means for removing the waste, a device can truly suffer.

To best accomplish this, our team takes into account the many unique parameters that need to be met in order to provide effective application cooling. For applications looking to dissipate waste entirely, we recommend our Copper Finned Heat Sink.

Speedy Heat Transfer

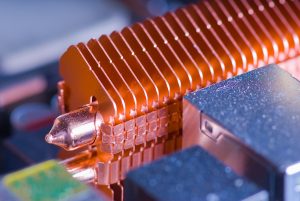

Heat sinks utilize a thermal management concept known as dissipation, which involves first spreading waste energy apart and out into the surrounding air, where the subsequent result is elimination.

A custom sink is designed in a manner where the bottom portion is flat like a plate and placed at the heat source. From here, the energy is absorbed into the base and transferred to a number of fins that are attached, allowing the energy to disperse. From here, it is released into the surrounding air and you and your team do not have to experience contamination or workplace pollution. For more information about this process, reach out to our team today.

Fin Customization

As we mentioned before, every application is not created equally, and different environments and parameters require different solutions. We utilize copper in our products because it has an extremely high effective rate of thermal transfer. We also offer customization in fins, including how many, how tall they protrude, and how wide or thick they are. Reach out to our team to learn more about your customization options, or to get started on your custom product.

Learn More Today

For more information about our products and how they can help optimize your applications, reach out to Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a member of our team today.