Getting the most out of your heat exchanger has become a must for a variety of industries nowadays. Whereas prevention of overheating was the top priority in the past, efficiency and productivity are the major concerns of the present. What’s more, a demand has been created for accessories that can accomplish these goals while also taking up as little space as possible, somewhat throwing a wrench into the equation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discuss the ways that our custom products such as our cold plates can meet these parameters and help you get the most out of your equipment.

Getting the most out of your heat exchanger has become a must for a variety of industries nowadays. Whereas prevention of overheating was the top priority in the past, efficiency and productivity are the major concerns of the present. What’s more, a demand has been created for accessories that can accomplish these goals while also taking up as little space as possible, somewhat throwing a wrench into the equation. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discuss the ways that our custom products such as our cold plates can meet these parameters and help you get the most out of your equipment.

High-Performance in Tight Spaces

It goes without saying that as power densities per square inch continue to increase exponentially, the space allotted to accomplish effective thermal management is forever decreasing. That being said, heat exchangers must be designed to accommodate these needs.

To accomplish this, the team at Noren creates and manufactures products that are custom tailored to the needs of your specific parameters. For instance, our custom cold plates are relatively flat aluminum plates that contain internal tubing to help provide adequate cooling. What’s more, they can utilize a pumped liquid coupled with phase-change technology to accomplish this same goal. In order to function optimally, versatility and customization must play a role. For more information about this process, contact our team today.

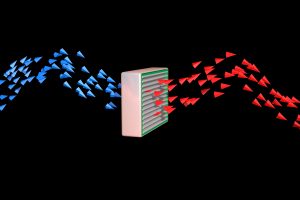

Conduction Through Phase-Changes

In addition to the passive options for thermal management, our cold plates can be created using phase-change technology. This method utilizes a fluid’s latent heat of vaporization in order to transfer waste heat over great distances. You see, the fluid is present at the heat source where it will absorb the waste and continue to increase in temperature. Once it reaches its point of vaporization, the fluid changes states of matter and transforms into a gas or vapor. From here, the vapor is carried across the internal tubing of the cold plates where it is deposited at and spread through the other plate. Once it has cooled, it returns back to its liquid state where the process repeats itself. To learn more about this process, reach out to our team today.

Addressing the Needs of Various Applications

One of the major benefits of cold plates – as well as our other products – is that they can be custom-tailored to meet the needs of your specific industry. In other words, our team works with yours to create the ideal heat exchanger that can utilize as much (or as little) space that is allotted, as well as give you the most out of your solution.

Speak with Our Team

For more information about the role of custom cold plates or to speak to a member of our team, contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 today.