As many other forms of technology have become increasingly more complicated as they’ve advanced, modern electrical cooling solutions have followed the trend of simplification. For example, in conventional cooling solutions, the most-often relied on solutions included air conditioning and air compression processes that created cold air to prevent overheating. Today, however, more advanced and efficient thermal management solutions are designed to simplify the process by utilizing an eco-friendly cooling fluid to absorb and transfer the heat continuously. Though the heat transfer process is significantly more streamlined, it’s also capable of producing higher-performance electrical cooling with greater efficiency.

As many other forms of technology have become increasingly more complicated as they’ve advanced, modern electrical cooling solutions have followed the trend of simplification. For example, in conventional cooling solutions, the most-often relied on solutions included air conditioning and air compression processes that created cold air to prevent overheating. Today, however, more advanced and efficient thermal management solutions are designed to simplify the process by utilizing an eco-friendly cooling fluid to absorb and transfer the heat continuously. Though the heat transfer process is significantly more streamlined, it’s also capable of producing higher-performance electrical cooling with greater efficiency.

The processes of absorbing and transferring heat

The processes of utilizing cold air that more conventional cooling solutions relied had several different drawbacks for companies as they’ve invested in more advanced technologies. Such solutions require large amounts of energy and large, complicated machinery with many different external moving parts. However, because heat exchangers don’t rely on cold air, they don’t require the same amount of energy or machinery to create and circulate it. Absorbing and transferring waste heat involves the natural properties of a cooling fluid, such as water, to collect heat without allowing for any rise in temperature in the surrounding air. Once the fluid collects enough heat, it transfers and dissipates it in a heat sink.

Heat transfer process inside of modern heat pipes

Transferring electrical waste heat in a continuous loop is the foundation of how modern heat exchangers work, but different cooling solutions are able to utilize the process to maximum effect according to each application’s needs. For instance, some modern heat exchangers are designed as heat pipes, which consist of metal pipes that bend, lie flat, and fit into most application’s designs with optimal efficiency. The fluid transfers heat through the pipes to the heat sink in a highly efficient manner, and because it all occurs within a tightly sealed loop, companies don’t need to consistently maintain or repair the heat exchanger.

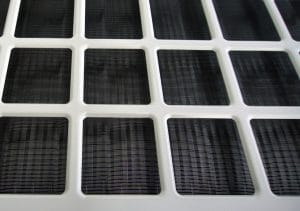

The high-performance cooling of custom cold plates

In addition to high-performance heat pipes, companies also often utilize advanced cold plate heat exchangers, which consist of an appropriate number of custom-machined cold plates stacked together. Within each plate, the flow paths are machined to optimize the fluid’s flow given the application’s specific parameters. Cold plates are able to absorb waste heat across a larger area with optimal efficiency, and can be utilized for a wide range of applications in virtually every industry. For more information about what transferring heat means in modern heat exchangers, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.