As companies invest in increasingly more advanced technological applications, the need for efficient and high-performance electrical cooling has become more diverse. The different uses, sizes, shapes, and demands of modern electrical enclosures has become nearly endless, and often, traditional methods of electrical cooling are unable or too costly to keep up. This need has given rise to companies in every industry adopting more modern and efficient cooling processes, often in the form of modern heat exchangers. Their ability to rapidly transfer electrical waste heat makes heat exchangers a highly efficient solution for companies’ various electrical cooling needs, and that efficiency has had significant benefits in several areas.

As companies invest in increasingly more advanced technological applications, the need for efficient and high-performance electrical cooling has become more diverse. The different uses, sizes, shapes, and demands of modern electrical enclosures has become nearly endless, and often, traditional methods of electrical cooling are unable or too costly to keep up. This need has given rise to companies in every industry adopting more modern and efficient cooling processes, often in the form of modern heat exchangers. Their ability to rapidly transfer electrical waste heat makes heat exchangers a highly efficient solution for companies’ various electrical cooling needs, and that efficiency has had significant benefits in several areas.

Thermal management without chilled air

Traditional electrical cooling systems, such as air conditioners and air compressors, are designed to keep electrical enclosures from overheating by utilizing a continuous source of chilled air. This core process is what often makes electrical thermal management a burden for companies, particularly the more reliant they are on advanced technologies. Transferring waste heat means preventing electrical overheating without having to rely on chilled air to do it. This means cooling units that utilize heat transfer processes don’t require the same amount of energy, and can be designed to prevent overheating using streamlined, easier-to-manage cooling apparatus.

Maximum cooling with minimal energy

The reduced energy needs associated with more modern cooling processes stems from their more natural methods of transferring heat, but using less energy doesn’t make the heat transfer process less effective. On the contrary, modern cooling units that are designed to continuously transfer waste heat can often maintain electrical cooling at a greater rate than many traditional solutions. Harnessing the natural properties of an eco-friendly cooling fluid, including its ability to absorb heat without allowing for any rise in the surrounding temperature, can allow modern heat exchangers to accomplish high-performance electrical cooling for many of the most demanding technological applications.

More reliable thermal management processes

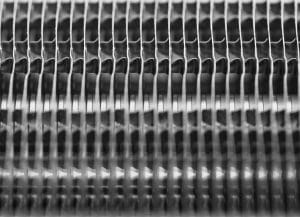

The more companies transform their operations with technology, the more important it becomes to ensure that technology can run efficiently and reliably on a consistent basis. Electrical thermal management that’s powered by traditional solutions can be prone to frequent maintenance needs and downtime due to unscheduled repairs. By contrast, more modern cooling solutions don’t consist of many different external mechanical parts, like air conditioners. Most utilize an eco-friendly cooling fluid that flows easily through heat pipes or custom cold plates. Their streamlined design helps ensure that modern heat exchangers can continue operating at maximum efficiency.

For more information about more modern and efficient cooling with heat exchangers, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.