Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods.

Cooling electrical enclosures may not seem like an area ripe for innovation, but not long ago, such electrical thermal management concerns were significant to companies in most industries. That’s because the most common thermal management solutions, such as air conditioners and compressed air units, were often costly and cumbersome to operate. However, they were necessary, so companies accepted those concerns. Heat exchangers became the more popular electrical cooling solution because they revolutionized how companies approached thermal management. The eco-friendly cooling units rely on transferring waste heat instead of overcoming it with chilled air. For example, plate heat exchangers utilize a combination of cold plates and eco-friendly cooling fluid to remove waste heat in a much more efficient and reliable manner than more conventional methods.

How Cold Plate Heat Exchangers Work

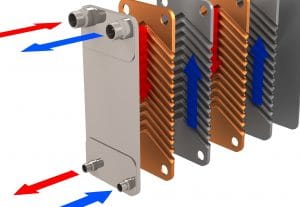

A heat exchanger is designed to prevent electrical overheating by redirecting waste heat as soon as electrical components emit it. Compared to air conditioners and compressors, this process is significantly simpler, and doesn’t require the use of complicated, energy-inefficient machinery. In a cold plate heat exchanger, for instance, the plates carry cooling fluid through the paths that are carefully machined into them. The heat that the plates are exposed to is absorbed by the fluid, which transfers the heat as it flows through the machined paths toward a cooler area, where it can dissipate the heat.

When Are They Most Appropriate?

These days, there are many different types of heat exchangers, each designed for virtually any electrical cooling need. In many cases, cold plates are appropriate for several reasons. Because cold plates can be conveniently stacked, they can successfully manage large amounts of electrical waste heat on a continuous basis. The plates can also absorb waste heat across large surface areas, making them ideal for several different types of high-performance applications.

The Value in Custom Thermal Solutions

For unique applications that require custom thermal management solutions, cold plate heat exchangers are often the most effective and efficient solution. That’s especially true for applications outside of traditional electrical enclosure cooling. For example, processes such as pasteurization within the food and beverage industry often benefit from the consistent, uniform, and eco-friendly thermal management capabilities of plate heat exchangers. Because of their versatility, plate heat exchangers can also be custom-designed to fit the unique specifications of newer, more innovative technologies, such as military and aerospace applications.

For more information about the benefits of custom thermal solutions such as cold plates, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.