While there are several ways to address the many thermal management challenges that can arise with any application, the concept of a thermosyphon has become an increasingly more popular one. Thermosyphons describe innovative heat transfer mechanisms that combine phase-change cooling principles with the force of gravity to create an eco-friendly, closed-loop system for eliminating electrical waste heat. Today, we examine how the method occurs and how heat exchangers utilize thermosyphon technology to provide efficient, reliable, and highly effective electrical thermal management solutions to all industries.

While there are several ways to address the many thermal management challenges that can arise with any application, the concept of a thermosyphon has become an increasingly more popular one. Thermosyphons describe innovative heat transfer mechanisms that combine phase-change cooling principles with the force of gravity to create an eco-friendly, closed-loop system for eliminating electrical waste heat. Today, we examine how the method occurs and how heat exchangers utilize thermosyphon technology to provide efficient, reliable, and highly effective electrical thermal management solutions to all industries.

The Effects of Phase-Change Cooling

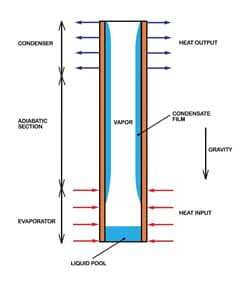

Phase-change cooling is the process of utilizing a fluid’s latent heat of vaporization to transfer heat. As a liquid, it absorbs the excess heat, evaporating as it does so without any notable rise in temperature. Within a thermosyphon, this liquid remains at the bottom of the enclosure until it is superheated enough to evaporate. Then, the vapor rises to a condenser at the top, where the fluid can safely release its thermal energy and condense back into liquid. The denser liquid falls back to the evaporator section at the bottom of the thermosyphon, and the process repeats itself in a continuous cycle as long as waste heat is being emitted.

The Benefits Over Other Cooling Methods

Thermosyphons allow heat exchangers to effectively prevent electrical overheating in a more efficient and minimalistic manner than many other thermal management solutions. This generates several benefits, including a reduced overall need for energy consumption and fewer interruptions to operations for scheduled maintenance, unexpected repairs, and more. Also, because the fluid cycles through a closed-loop, heat exchangers that utilize thermosyphons don’t have to be refilled.

For more information about thermosyphons and heat exchangers, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.