When you work to create items with plastic, many things can go wrong, and hate can be a major source of frustration. Injection molded plastic production requires a dedicated approach to thermal management, as the wrong temperatures can increase your cycle times, decrease the quality of your products, and more. If you are struggling with your traditional thermal management design, talk to an expert about ways to better your approach and keep your production floor optimized to meet the needs of your industry.

When you work to create items with plastic, many things can go wrong, and hate can be a major source of frustration. Injection molded plastic production requires a dedicated approach to thermal management, as the wrong temperatures can increase your cycle times, decrease the quality of your products, and more. If you are struggling with your traditional thermal management design, talk to an expert about ways to better your approach and keep your production floor optimized to meet the needs of your industry.

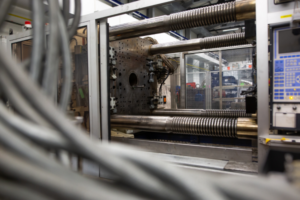

At Noren Thermal Solutions in Taylor, TX, we understand the importance of efficiency. That is why for over 55 years, we have been working tirelessly to design and develop quality thermal management concepts to help businesses just like yours to better handle their heat in more effective ways. With custom heat pipe assemblies, air-to-water heat exchangers, and more, our team is here to help you regulate your heat and protect your vital electronic components and wiring. For injection molded plastic production, we also design specified thermal pins, aimed at giving you more control over the thermal energy within your molds. To find out more, give us a call today!

Are You Still Relying On Traditional Methods Of Thermal Management?

If you are still depending on compressed air or air conditioning to keep your equipment safe, it is time to talk to an expert about your options. There are new and advanced thermal management possibilities available to you, and our team at Noren is here to help you to find the right solution for your company. We also understand that not every business is exactly the same, which is why we design and develop custom thermal solutions, giving you a system that has been crafted specifically for your needs.

Thermal Pins Provide Effective Cooling For Injection Molded Plastic Production

If you are struggling with your thermal management in injection molded plastic production, then you could be experiencing one or more of a wide variety of problems. Your products could wind up inconsistent or of poor quality, leaving you with nothing to show for your hard work except a lot of trash. Your cycle times could also become longer and longer, decreasing your profit margins. With thermal pins, you have a customizable thermal management design that can reach tough areas. Our team creates efficient thermal pins, helping you to get back to doing what you love.

Discover Your Thermal Management Options With Noren!

When you work in injection molded plastic production, you need to keep a close eye on your thermal energy. To find out more about the advantages of thermal pins for injection molding, give us a call at Noren Thermal Solutions in Taylor, TX at 512-595-5700 today!