If your company employs sophisticated electronic equipment in your daily operations, they produce waste heat that must be properly managed to keep your operation online. This means planning for your temperature control needs can prevent problems with overheating or lagging of your computer systems. When your system goes down due to thermal mismanagement, repair bills can skyrocket while labor that relies on your computers becomes unproductive. To best serve your bottom line, plan by consulting a team that specializes in protecting equipment from waste heat.

If your company employs sophisticated electronic equipment in your daily operations, they produce waste heat that must be properly managed to keep your operation online. This means planning for your temperature control needs can prevent problems with overheating or lagging of your computer systems. When your system goes down due to thermal mismanagement, repair bills can skyrocket while labor that relies on your computers becomes unproductive. To best serve your bottom line, plan by consulting a team that specializes in protecting equipment from waste heat.

At Noren Thermal Solutions, we provide a suite of custom products to meet the majority of your cooling needs. We know that disposing of waste heat may not be your main concern, but it is ours. That is why we have been helping companies like yours for over half a century implement custom solutions to protect their applications from overheating. When you understand how products like heat sinks and cold plates keep your machinery safe, you can feel confident that your valuable equipment is in good hands.

Using A Cold Plate To Transfer Waste Heat From Your Sensitive Electronics

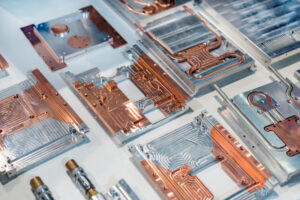

Across all sectors and industries, a wide variety of electronic devices produce heat while operating, which must be dealt with. One option for transferring thermal energy is a cold plate that can directly contact your application. By absorbing its temperatures, a cold plate conducts them to a safer location where the original equipment will not overheat or begin to lag. At Noren, we design our plates from aluminum that holds a tube inside. By pumping a cooling liquid through the tube, heat transfers as the liquid is directed elsewhere. This method of surface touch is called direct contact cooling and may be combined with other products such as heat sinks to form larger thermal management systems.

Take Advantage Of A Copper Heat Sink When Designing Your Systems

If you are looking to reduce the costs of your thermal management technology, passive heat exchange provides a valuable alternative to traditional air conditioning methods. A copper heat sink is one such piece of technology. They operate by composing a series of copper fins that absorb temperatures from the surrounding air. By attaching a heat sink to your chipsets or motherboard, the increased surface area provided by the individual fins allows you to take in a great amount of energy. You may also transfer waste heat from a cold plate into the heat sink to better store it after direct contact cooling.

Protect Your Valuable Equipment From Heat With Technology from Noren Thermal Solutions

If you are designing a system to protect your company’s electronic infrastructure, we are happy to help! To learn more about how we help you manage waste heat, speak with a valued member of our team at Noren Thermal Solutions at (512) 595-5700.