If you operate a business that generates significant amounts of waste heat, anticipating your thermal management needs requires expertise. If you are unfamiliar with these processes, receiving quality consultation from a team of professionals can help you keep your operation running smoothly without unpredictable delays. Problems with overheating can spike costs when you lose productivity or require expensive repairs to your valuable equipment. This means that maintaining your internal temperatures is a top priority when expanding your reliance on circuitry and other electrical equipment. To prevent safety risks from overheating, contact a member of our team to take a look at your equipment.

At Noren Thermal Solutions, we have been helping companies like yours achieve their waste heat management goals for half a century. When you rely upon a team like yours, you can discover that cost-effective thermal management is easily accessible. By discovering the differences between cold plates and heat sinks, you can learn how each can be a vital part of your thermal management system.

Cold Plates Help Protect Your Surfaces

When you have a sensitive surface area that is susceptible to high temperatures, a cold plate can move heat away and transfer it to a safer location. This device operates by sending cooling through an internal tube that runs through a plate of aluminum. As surface heat transfers into the aluminum plate, the cooling carries heat away from machinery connected to the outside. This device relies upon a method called direct contact cooling to achieve these goals. For situations where direct contact is available, a cold plate is an effective product for shifting your internal temperatures and protecting your equipment.

Transferring Your Waste Heat With The Aid Of A Heat Sink

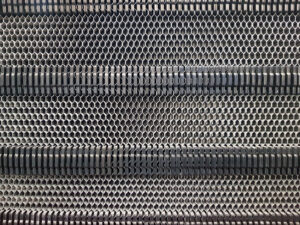

If you are looking to decrease the energy costs of your current thermal management equipment, consider a product that relies upon passive heat exchange. A heat sink can attach to a circuit board to absorb heat from the surrounding air. This device contains a system of many folds in direct succession to expand the total surface area for transfer.

We can combine both heat sinks and cold plates to help you best move your excess waste energy. A cold plate could collect energy with direct contact and move it towards a heat sink. This helps store dangerous temperatures away and reduces the likelihood of overheating electronic circuitry.

Helping Protect Your Valuable Equipment From Heat With Noren Thermal Solutions

Relying upon a team of thermal management professionals can help you reach your goals when expanding electronic equipment. We could design a custom solution for your company today. To learn more about methods for managing waste heat, speak with a valued member of our team at Noren Thermal Solutions in Taylor, TX at (512)595-5700.