In our most recent blog post, our team took a look at the important role of thermal accessories and why we need to ensure applications have methods in place for regulating waste heat production. Indeed, there are several factors that can negatively influence your industrial application’s ability to function properly, and taking care to address these concerns with a custom heat exchanger can truly help you optimize your setup. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind cold plate heat exchangers and how they can be used to cool large areas.

In our most recent blog post, our team took a look at the important role of thermal accessories and why we need to ensure applications have methods in place for regulating waste heat production. Indeed, there are several factors that can negatively influence your industrial application’s ability to function properly, and taking care to address these concerns with a custom heat exchanger can truly help you optimize your setup. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the science behind cold plate heat exchangers and how they can be used to cool large areas.

High-Performance Thermal Transfer

If you are like many other individuals working in a specific industry, you would know that your line of work is very unique to you. What we mean by this is that there are often industry-wide standards that you not only have to follow but must be reflected through the equipment you use as well. While safety is always going to be a priority concern, how you manage waste heat matters greatly as well.

Indeed, overheating is the most common issue applications are plagued with, as oftentimes they are created without a natural means of ridding waste heat on their own. As a result, the heat can pool in the enclosure itself until reaching dangerous temperatures, which can lead to anything from temporary shutdown to permanent damage and even electrical fires.

In applications that utilize a lot of space, there is even more area to consider when implementing a heat exchanger. Fortunately, this is where our custom cold plate options come in to help. To learn more about this process and how our team can help you get started, give our staff a call today.

Effective for Large Areas

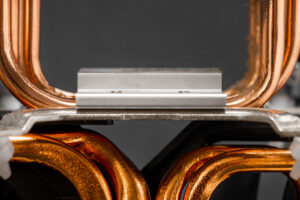

For purposes of this blog, a cold plate helps provide localized cooling through the transfer of heat. The dissipation process can occur through air, but can also be accomplished with the help of pumped liquid.

Large applications can benefit from cold plate heat exchangers because these products can provide high rates of thermal transfer. What’s more? The aluminum plate utilizes internal tubing in order to absorb the waste heat that is transferred through resistors. Contact our team to learn more today about your options.

Utilizing Pumped Liquid

In addition to our standard cold plate models, our team also offers liquid cold plates, which function by passing waste heat from the metal plate itself to the cooling fluid. This process utilizes phase-change cooling, which involves utilizing a fluid’s latent heat of vaporization to transfer waste energy in a sustainable manner.

Give Our Team a Call

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative from our team and learn more about the low-cost, high-efficiency of cold plate thermal management.