Are you still continuing to use compressed air or air conditioning to keep your equipment safe from the harms of heat? Your wiring and circuitry can generate significant thermal energy when in use, and this can lead to big problems for your company if you are not careful. Relying on an outdated or otherwise inefficient method of thermal management can leave you waiting around for repairs. Protect your investment with a better way.

Are you still continuing to use compressed air or air conditioning to keep your equipment safe from the harms of heat? Your wiring and circuitry can generate significant thermal energy when in use, and this can lead to big problems for your company if you are not careful. Relying on an outdated or otherwise inefficient method of thermal management can leave you waiting around for repairs. Protect your investment with a better way.

With our team of thermal management experts at Noren Thermal Solutions in Taylor, TX, you can safeguard your electronics, wiring and more with a more effective way of controlling your heat. We create a full range of highly efficient options for businesses of all shapes and sizes, and our team can help you to find the one that’s right for your operation. Thermal management is a vital aspect of maintaining your electronic equipment, and for over 55 years, our team has been here to help. Give us a call today to learn more!

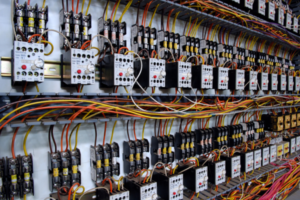

These days, electronic devices are just about everywhere that you look, and if your business relies upon them, you need to make sure that you are keeping them well-maintained. Your electronics can create significant heat during operation, and this can cause damage to their circuitry and wiring. Without

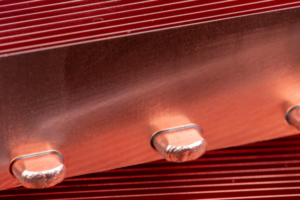

These days, electronic devices are just about everywhere that you look, and if your business relies upon them, you need to make sure that you are keeping them well-maintained. Your electronics can create significant heat during operation, and this can cause damage to their circuitry and wiring. Without  Heat pipes are quickly becoming a popular go-to solution in the world of thermal management. They have become a significant part of moving toward a more sustainable method of handling the heat, as people look toward better solutions than traditional means of thermal management, such as compressed air and air conditioning. If you are still relying on these methods to protect your equipment, take some time to learn about the way that

Heat pipes are quickly becoming a popular go-to solution in the world of thermal management. They have become a significant part of moving toward a more sustainable method of handling the heat, as people look toward better solutions than traditional means of thermal management, such as compressed air and air conditioning. If you are still relying on these methods to protect your equipment, take some time to learn about the way that  Your business depends on your equipment each and every day, and regulating heat within and around your electrical equipment is a key part of keeping things safe. Traditional methods of thermal management can be as expensive as it is inefficient, so if you are still relying on compressed air or air conditioning to keep your electronics and wiring within your electrical enclosures safe, it is time to think about making a change. When you want a

Your business depends on your equipment each and every day, and regulating heat within and around your electrical equipment is a key part of keeping things safe. Traditional methods of thermal management can be as expensive as it is inefficient, so if you are still relying on compressed air or air conditioning to keep your electronics and wiring within your electrical enclosures safe, it is time to think about making a change. When you want a If your operation relies on automated tech in order to run efficiently, you are far from alone. As these forms of technology develop, more and more industries are taking advantage of automation, and this means that they need to make sure they their equipment is well-maintained and optimized for the best system performance possible. From the world of semiconductor production to the rugged outdoors of oil and gas,

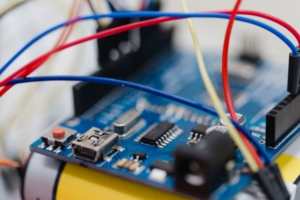

If your operation relies on automated tech in order to run efficiently, you are far from alone. As these forms of technology develop, more and more industries are taking advantage of automation, and this means that they need to make sure they their equipment is well-maintained and optimized for the best system performance possible. From the world of semiconductor production to the rugged outdoors of oil and gas,  These days, it is important for businesses to be careful with their resources. More than ever, your consumers are looking to you to be a responsible member of the community, and by

These days, it is important for businesses to be careful with their resources. More than ever, your consumers are looking to you to be a responsible member of the community, and by  These days, businesses depend on technology more than ever, and that means that this equipment needs to be protected in order to stay running smoothly. Your electronics and circuits create significant thermal energy during operation, and if you do not have the right protection for your equipment, it can cause problems both immediately and in the longer term. One of the ways that you can work to handle your heat is through the use of

These days, businesses depend on technology more than ever, and that means that this equipment needs to be protected in order to stay running smoothly. Your electronics and circuits create significant thermal energy during operation, and if you do not have the right protection for your equipment, it can cause problems both immediately and in the longer term. One of the ways that you can work to handle your heat is through the use of  As a business, you need to care for your equipment, and your electrical enclosures are an important part of that. These areas are true workhorses, and that means that they do serious work for your operation; they also

As a business, you need to care for your equipment, and your electrical enclosures are an important part of that. These areas are true workhorses, and that means that they do serious work for your operation; they also  Your customers want to know that you are putting for the right effort into doing what is right for the environment. This is becoming an increasing concern for people, and they make their purchasing decisions with this idea in mind. Thankfully, within the world of thermal management, there is an option that can help to

Your customers want to know that you are putting for the right effort into doing what is right for the environment. This is becoming an increasing concern for people, and they make their purchasing decisions with this idea in mind. Thankfully, within the world of thermal management, there is an option that can help to  In certain fields, the choice in equipment protection can mean more than reliable performance. If you work in the pharmaceutical or medical device arena, then you know how important it is that you do the job right. Lives depend on you making those key decisions, and cutting corners in thermal management for medical applications can become a big problem. That’s why

In certain fields, the choice in equipment protection can mean more than reliable performance. If you work in the pharmaceutical or medical device arena, then you know how important it is that you do the job right. Lives depend on you making those key decisions, and cutting corners in thermal management for medical applications can become a big problem. That’s why