Last week, our team took a look at the ins and outs of heat sink thermal management, including the way these devices utilize thermal dissipation to provide an eco-friendly solution. Indeed, heat exchangers are excellent tools to help regulate internal temperatures within a technological application, and most are created without thermal solutions in mind, to begin with. Fortunately, our team manufactures a variety of solutions to help address your unique needs, including those of plastic molds. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the unique parameters of plastic mold cooling and how our solutions can address a variety of needs.

Last week, our team took a look at the ins and outs of heat sink thermal management, including the way these devices utilize thermal dissipation to provide an eco-friendly solution. Indeed, heat exchangers are excellent tools to help regulate internal temperatures within a technological application, and most are created without thermal solutions in mind, to begin with. Fortunately, our team manufactures a variety of solutions to help address your unique needs, including those of plastic molds. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX discusses the unique parameters of plastic mold cooling and how our solutions can address a variety of needs.

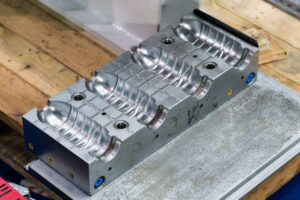

Major Features of Our Thermal Pins

When looking at plastic thermal management, we immediately are met with a set of unique factors to consider, as variations in mold thickness make it difficult for any one-size-fits-all solution to make a noticeable difference. Indeed, many companies jump on to the all-in-one solutions for promises of saving money and still meeting your needs, however, this is hardly ever the case.

You see, one-size-fits-all heat exchangers are unable to properly meet your needs, as they are not constructed with your unique parameters in mind, to begin with. Not only does this lead to sub-optimal function, but it can even cause major complications down the line. In other words, it is more cost-effective to seek a custom thermal solution than a uniform one.

Whether you are aware of it or not, your physical environment, type of application, materials used, and other factors all influence your application’s ability to function at full capacity. This is where custom thermal pins come in to help. To learn more about this process, give our team a call today.

Consistent Cooling Regardless of Mold Thickness

As part of their manufacturing or production process, a host of different industries may utilize plastic mold cooling. Moreover, there are several different methods that can be utilized depending on the outcome or intended goal, but each requires a solution for rapid cooling.

Thermal pin heat exchangers are considered to be high temperature miniature heat pipes, and are used to reach all areas of the mold, regardless of mold thickness. Contact our team to learn more.

Benefits of High Temperature Heat Pipes

Thermal pins can help provide plastic injection mold cooling as well as plastic extrusion mold cooling, as well as assist in applications specially designed for blow and rotational mold cooling. Not only do they assist in removing waste heat quickly, but they are able to do so without causing noticeable product blemishes such as pulling, spotting, or sink marks.

Let’s Get Started Today

There may be several different plastic mold cooling needs, but our team offers custom solutions for them all. Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak to a representative from our team and get started on your thermal solution today.