Overheating is the most common issue shared among technological applications across all industries. Indeed, growing internal temperatures present a major obstacle in terms of functionality, production, and profit. This means that, in order to stay in the running in a highly competitive industry, you must consider these factors and enact a plan to address it. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at what it means to provide even cooling in plastic mold processes, and how consistency can lead to greater-quality products.

Overheating is the most common issue shared among technological applications across all industries. Indeed, growing internal temperatures present a major obstacle in terms of functionality, production, and profit. This means that, in order to stay in the running in a highly competitive industry, you must consider these factors and enact a plan to address it. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at what it means to provide even cooling in plastic mold processes, and how consistency can lead to greater-quality products.

A Need for Rapid, Consistent Cooling

It goes without saying that your applications are an essential part of your overall operation. Not only can they help perform routine tasks at a greater rate than that of individual workers, but it allows you to reallocate your staff’s time, effort, and energy into other, more detail-specific tasks. In other words, it’s a win-win!

What you need to recognize through this process, however, is that there are various factors that can complicate these capabilities, and overheating is a primary player. Indeed, seeking the help of a custom heat exchanger can elevate your functionality, and our team is more than happy to help you get started.

Whether you are working outside and in need of an electrical panel heat exchanger, or you simply require a custom accessory to enhance your capabilities, our team has you covered. We take the time to truly get to know you and your needs, as well as utilize your unique parameters to help you achieve the best possible solution. To learn more about this process, give our team a call today.

Types of Applications That Benefit

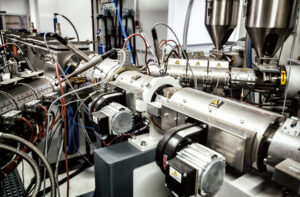

If we take a more detailed look at plastics, we see a very noticeable need for rapid and consistent heating and cooling. After all, being able to produce high-quality plastic products with optimal cycle times is a must for competitive industries, and the shorter those cycle times become, the better off you will be.

What you might not know, however, is that there are various ways to produce plastic products, but thermal pins can be customized to meet the needs of all. For example, plastic injection mold cooling utilizes injection processes to help reach areas previously inaccessible to remote water cooling, whereas plastic rotational mold cooling involves rapid heat transfer regardless of mold thickness. Give our office a call today to learn more.

Pursuing Custom Solutions

Although one-size-fits-all solutions may tout the ability to address your needs regardless of your industry, in actuality, you are only able to achieve a fraction of what a custom solution could provide you. Moreover, it is more cost-efficient in the long run to meet your needs precisely, thus helping you get the most from your application.

Speak With Our Team

Contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 to speak with a representative from our team and learn more about the ways thermal pin heat exchangers optimize plastic capabilities.