Ensuring that your business stays ahead of the curve typically involves considering a number of factors. Indeed, these can include keeping tabs on the competition, utilizing top-of-the-line equipment, and ensuring your setup is ideal for optimal thermal management capabilities. Though success often involves a combination of these and other factors, it is important to also have an understanding of the method to the madness, meaning what causes your equipment to function in the first place. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the major components involved in application cooling, and how we utilize eco-friendly methods along the way.

Ensuring that your business stays ahead of the curve typically involves considering a number of factors. Indeed, these can include keeping tabs on the competition, utilizing top-of-the-line equipment, and ensuring your setup is ideal for optimal thermal management capabilities. Though success often involves a combination of these and other factors, it is important to also have an understanding of the method to the madness, meaning what causes your equipment to function in the first place. In today’s blog, the team at Noren Thermal Solutions in Taylor, TX takes a look at the major components involved in application cooling, and how we utilize eco-friendly methods along the way.

Heat Spreaders

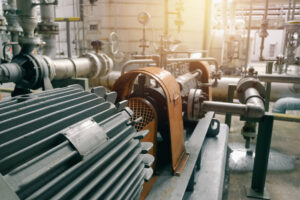

It goes without saying that, just as a human sprinting a marathon can quickly overheat without rest or water, so, too, can machinery. Of course, we are not implying that you should give your equipment water to keep going, but that overheating is a major concern for any technology. You see, mechanical function tends to generate waste heat, and without a method, for this waste heat to be removed, it will cause internal temperatures to increase greatly. Once these temperatures reach a certain point, the result will include temporary shutdown due to overheating, permanent damage, and even electrical fires.

To avoid this, it is highly recommended that your business looks into a method for removing waste heat. One such component that can benefit a number of applications includes a heat spreader. This consists of a device that contains a high rate of thermal transfer or conductivity to help displace the waste energy in a rapid manner. To learn more about this thermal solution component, reach out to our team today.

Sinks or Pipes?

Two other very important thermal solution components that can be used in tandem with other options include the heat sink and the heat pipe. A sink consists of a solid base with multiple perpendicular fins jutting out from it, allowing heat to spread and dissipate rapidly. On the other hand, a pipe assembly is used to carry thermal energy away from the heat source so that your application does not overheat. Both options offer significant benefits, and the one that works best for you will largely depend on your unique needs and parameters. Reach out to our team to learn more today.

Utilizing Eco-Friendly Methods

What makes our products so unique is that we place an equal emphasis on optimal function as well as eco-friendly solutions. Indeed, we utilize natural methods such as passive/active cooling and phase-change methods to provide the most when it comes to internal temperature regulation without harming the physical environment or your working one.

Speak with Our Team

For more information about the thermal solution components that comprise our products, or to speak to a representative from our team, contact Noren Thermal Solutions in Taylor, TX by calling 512-595-5700 today.