Many of the most important trends in manufacturing and other industries have involved implementing advanced technologies to improve key efficiencies and overall productivity. However, more recently, trends and changes in processes have also become focused on creating more natural and eco-friendly processes, especially in the realm of electrical thermal management. For example, for many companies, the use of eco-friendly heat exchangers has proven a valuable element in their quest to lower their environmental footprints. This is thanks largely to their ability to handle large amounts of electrical waste heat consistently, with minimal amounts of energy, and with a limited impact on the environment.

Many of the most important trends in manufacturing and other industries have involved implementing advanced technologies to improve key efficiencies and overall productivity. However, more recently, trends and changes in processes have also become focused on creating more natural and eco-friendly processes, especially in the realm of electrical thermal management. For example, for many companies, the use of eco-friendly heat exchangers has proven a valuable element in their quest to lower their environmental footprints. This is thanks largely to their ability to handle large amounts of electrical waste heat consistently, with minimal amounts of energy, and with a limited impact on the environment.

The environmental impacts of conventional cooling

Eco-friendliness can mean many different things in different industries, but generally, it involves finding ways to lower the impact that a company’s operations have on the surrounding environment. In electrical thermal management, these impacts conventionally stemmed from the cumbersome requirements of traditional cooling solutions. For example, with more conventional air conditioners and air compressors, the process of electrical cooling centers on the generation and circulation of chilled air. This requires substantial amounts of energy to facilitate, and the machinery utilizes chemicals and substances that could prove harmful to the environment.

The more natural methods of modern heat exchangers

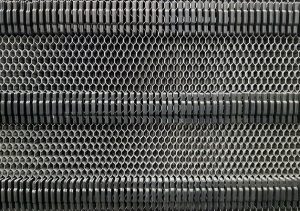

The use of conventional electrical cooling solutions can become burdensome in many different ways, from the need for more energy to the potential impact they can have on a company’s environmental footprint. As companies in every industry continue adopting more advanced forms of technology, these burdens have become immense. To eliminate them, many companies turn to more natural and efficient heat exchangers, which don’t rely on the same methods of chilling and circulating air. Modern heat exchangers are designed to prevent electrical overheating by creating a loop in which an eco-friendly cooling fluid can continuously absorb and transfer electrical waste heat. The process of continuous heat transfer doesn’t require complicated HVAC equipment or the same large amount of energy, making it a more eco-friendly solution for modern electrical cooling.

The focus on eco-friendly electrical cooling

The advantages that stem from utilizing more streamlined electrical cooling cover a wide range of areas. For example, without the same level of mechanical operation, heat exchangers can accomplish high-performance electrical thermal management with minimal amounts of energy and maintenance. In addition, the reduced energy and use of more eco-friendly cooling fluids means modern heat exchangers are inherently designed to operate with a greater level of environmental friendliness. For more information about the role of heat exchangers in eco-friendly production, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.